Полностью автоматическая упаковочная машина для чайных

- Категория: Boxing Machines >>>

- Поставщик: Dongguan,Longxingjian,Intelligent,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 190400.60 $* | 199920.37 $* |

| Aug-17-2025 | 188800.7 $* | 198240.49 $* |

| Jul-17-2025 | 158400.55 $* | 166320.8 $* |

| Jun-17-2025 | 185600.70 $* | 194880.52 $* |

| May-17-2025 | 161600.22 $* | 169680.73 $* |

| Apr-17-2025 | 182400.63 $* | 191520.62 $* |

| Mar-17-2025 | 180800.63 $* | 189840.92 $* |

| Feb-17-2025 | 179200.92 $* | 188160.76 $* |

| Jan-17-2025 | 177600.44 $* | 186480.88 $* |

Характеристики

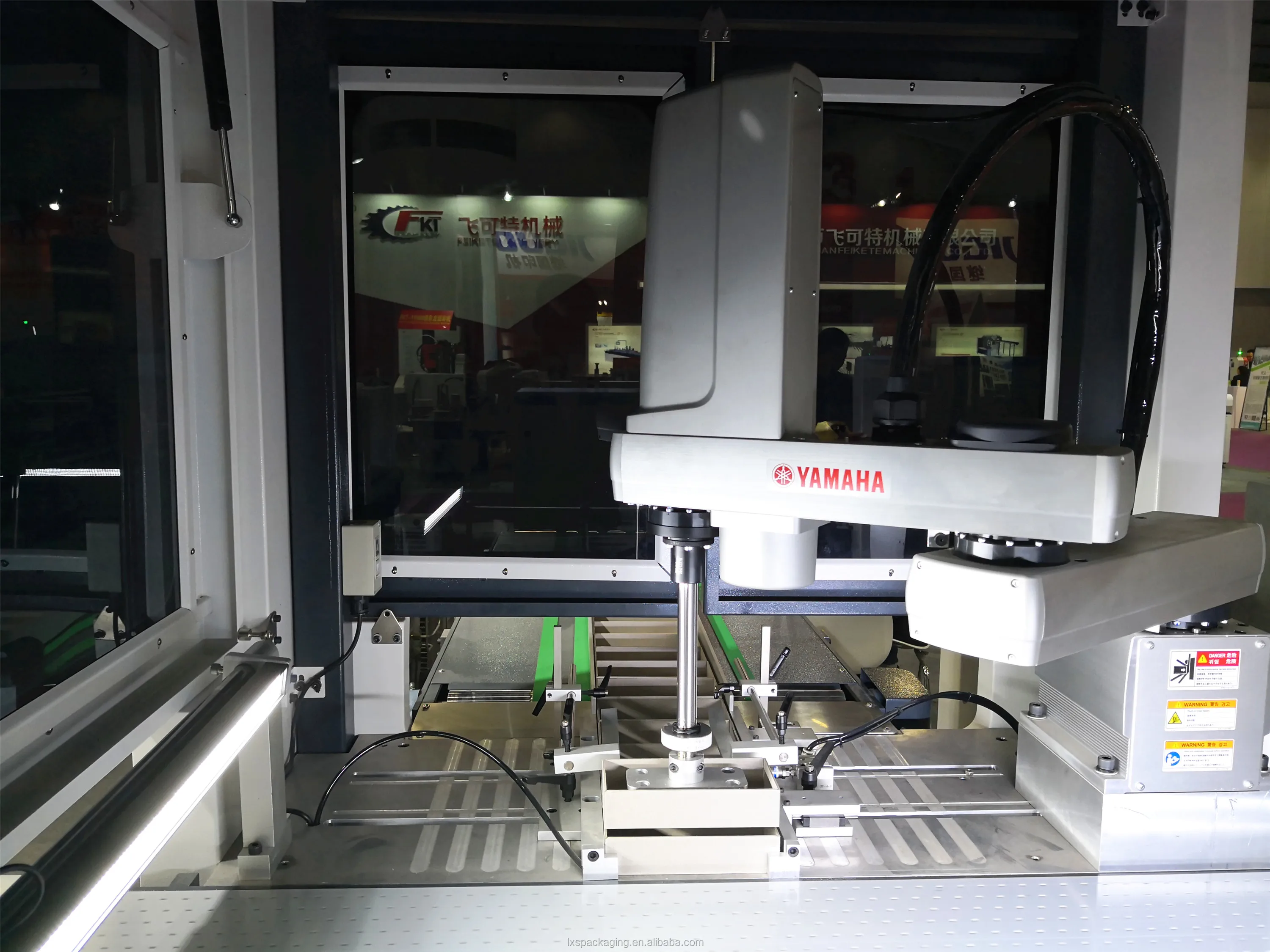

6. Mitsubishi servo motor

7. Panasonic PLC

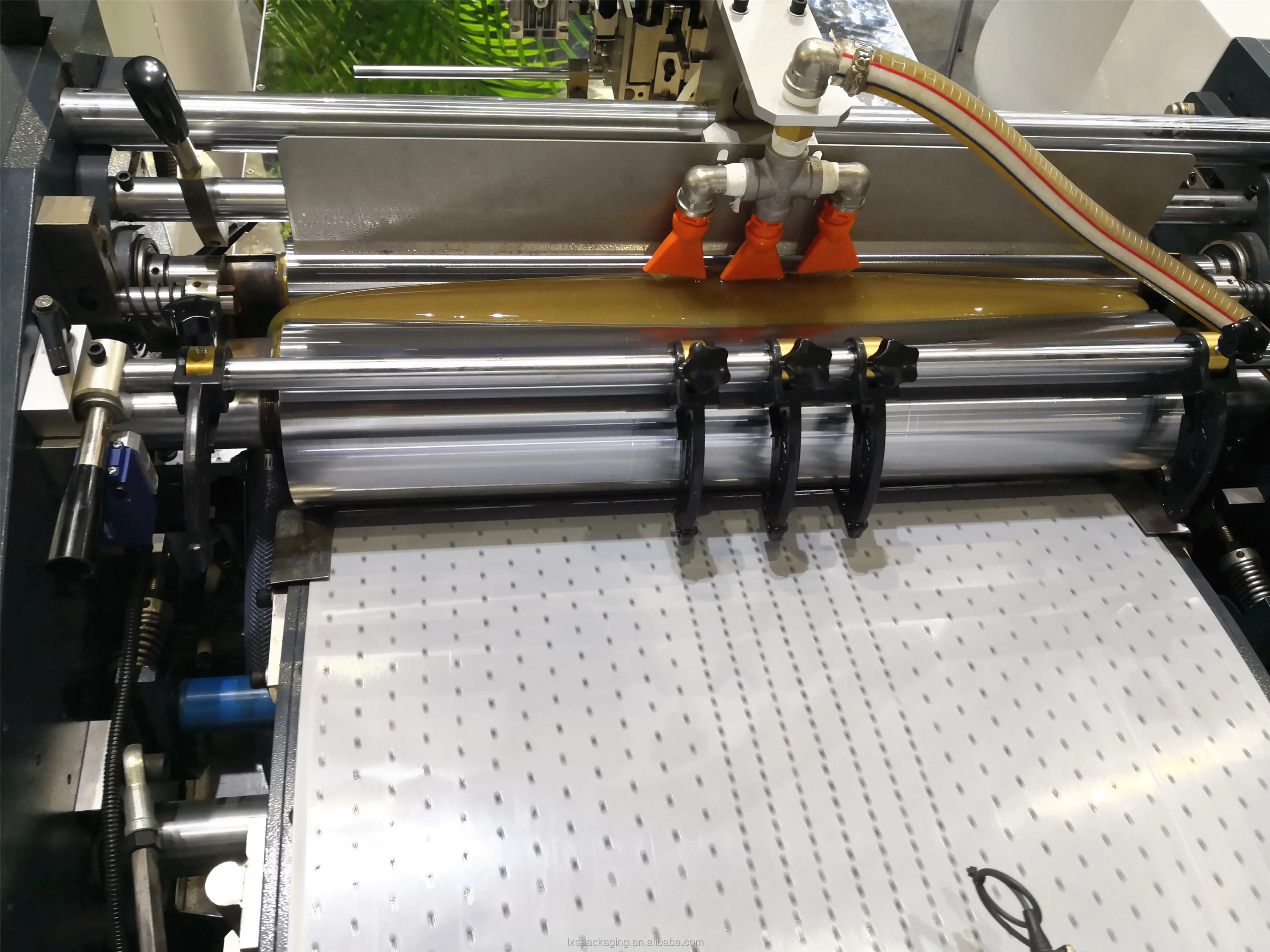

8. Anti-leaking gluing system

9. Servo motor feeding system

No need to change air pressing plate

No need to change tuck in blade

No need to move camera for size changing, quick job changing

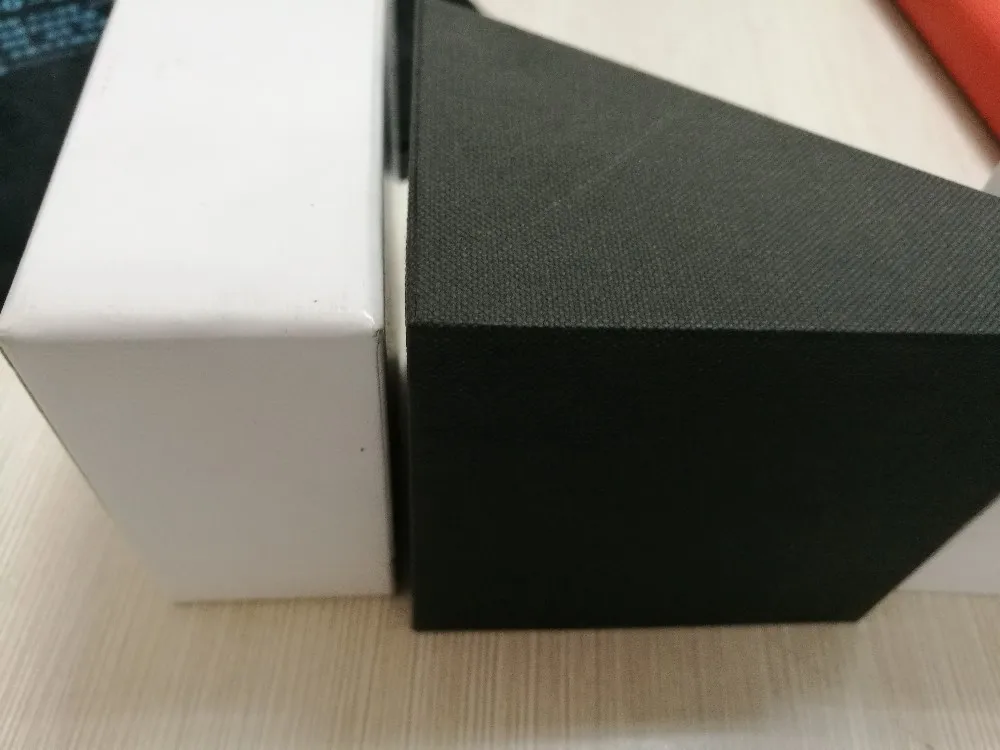

Make high-end boxes

Special pick up and wrapping system

Can use the carton paper to wrap the inner box

Can make big size box, such as 600*400mm, and the height can reach 120mm

Storage(memory) function for sizes setting

Suitable for changeable orders

Such as 10,000 pcs for one order

LS-1246B/D Automatic smart rigid box making machine | ||||

Machine model | LS-1246B | LS-1246D | ||

Paper size(max) | L800*W600mm | L800*W600mm | ||

paper size (min) | L150*W100mm | L150*W100mm | ||

Box size(length ) | L 80-600mm | L 80-600mm | ||

Box size(width) | W 65-400mm | W 65-400mm | ||

Box size(height) | H 15-120mm | H 15-120mm | ||

Max board size | L760*W560mm | L760*W560mm | ||

Min board size | L120*W100 | L120*W100 | ||

Paper thickness | 80-350g/㎡ | 80-350g/㎡ | ||

Working speed | 15-25 pcs/min | 15-45pcs/min | ||

Positioning accuracy | ±0.1 mm | ±0.1 mm | ||

Motor power | 14kw/380v 3 phase | 14kw/380v 3 phase | ||

Heating power | 8 kw | 8 kw | ||

Air pressure | 40L/min 0.8Mpa | 40L/min 0.8Mpa | ||

Weight of machine | 3800kg | 5000kg | ||

Machine dimension | L6600*W3500*H3000mm | L7600*W3800*H3000mm | ||

Machine dimension | L6600*W3500*H3000mm | L7600*W3800*H3000mm | ||

Pre-sale service.

* Inquiry and consulting support.

* Sample testing support.

* Factory visit.

* Order confirmation.

After-sale service.

* Machine installation and training in customer factory.

* Engineers available to service machinery overseas.

* On-line technology support.

* Free machine parts replacement during warranty.

* Whole life of machine service.

FAQ

1.What is LXS company machine warranty?----1 year warranty including free machine parts replacement ( consumables are not included).

2.Does your machine with CE certificate?----Yes.We have CE ,ISO9001 .

3.What is the production time while placing order?---- Within 7-30 workdays.

4.Do you have stock product to sell?----Normally we do,it depends on which models you inquired .

5.What is your lead time?----Within 5-30 workdays ,we will arrange your order upon receiving your 30% deposit on order and ship out the machine before receiving your 70% remaining payment.

6.Can LXS company handle shipping for customers?----Yes.(Please provide us your requested sea port and we can check the shipping cost from logistic company and arrange shipping for you.

7.Does the packing strong?----Yes, of course! All of our export packing is with strong wooden case,all are confirm to export packing standard.

8.How about after-sales service process?----When your machine has problem, just contact your sales and we will solve your problem ASAP.

9.Can your engineer come to us for installing the machine & handle problems?---Yes,we can.And it is free-cost for the installing & training for 7 work days,you just need to pay for the air tickets & accommodation for our engineer.

10.Are you a manufacturer?----Yes, we are a manufacturer with over 12 years professional experience .Welcome the exclusive agents in Europe/Asia/Africa/America to join us.

11.What is the minimum quantity for order?----1 set, we done business step by step with high quality products and excellent services.

12.Do you inspect the finished products?----Yes, each step of production products will be inspection by our QC department and the running inspection video will be sent to to you for your verification before shipping.

13.What’s the payment term?---FOB/CIF terms,payment by T/T 30% in advance,70% balance before shipping.(It is negotiable)

If you have any inquiry, please don’t hesitate to contact us. We will reply you at the first time as we can.

Best and regards,

Longxingjian Intelligent Equipment Co.,Ltd