Солевая хлоринаторная клетка bsv 15 г ремонтные пластины с титановыми электродами и

- Категория: Другой титан >>>

- Поставщик: Utron,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.29 $* | 0.30 $* |

| Aug-16-2025 | 0.17 $* | 0.50 $* |

| Jul-16-2025 | 0.87 $* | 0.12 $* |

| Jun-16-2025 | 0.64 $* | 0.50 $* |

| May-16-2025 | 0.18 $* | 0.11 $* |

| Apr-16-2025 | 0.29 $* | 0.85 $* |

| Mar-16-2025 | 0.28 $* | 0.71 $* |

| Feb-16-2025 | 0.20 $* | 0.42 $* |

| Jan-16-2025 | 0.49 $* | 0.23 $* |

Характеристики

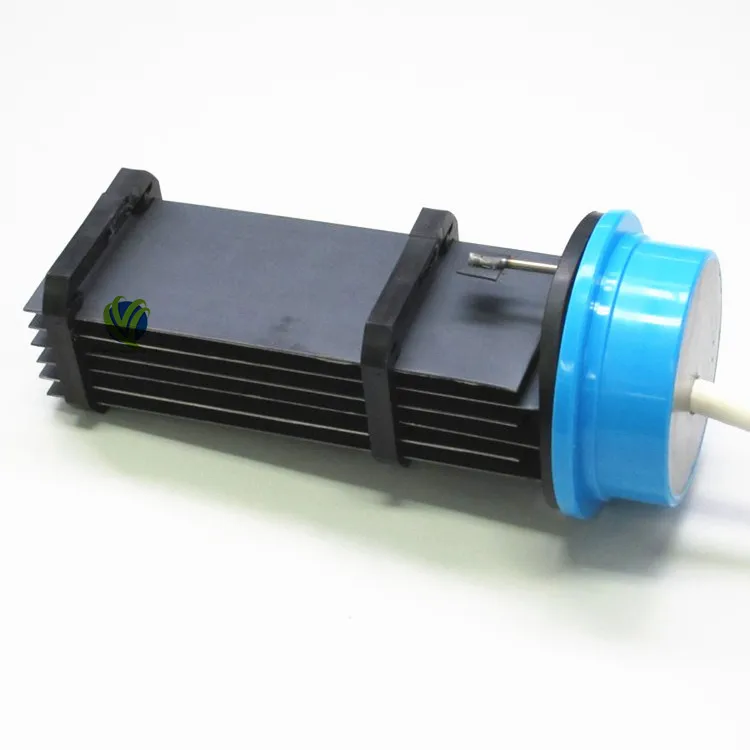

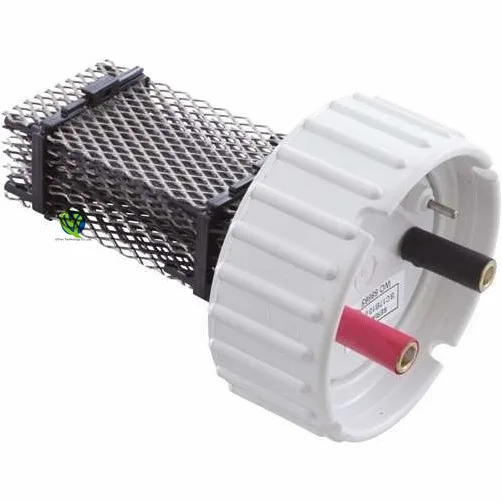

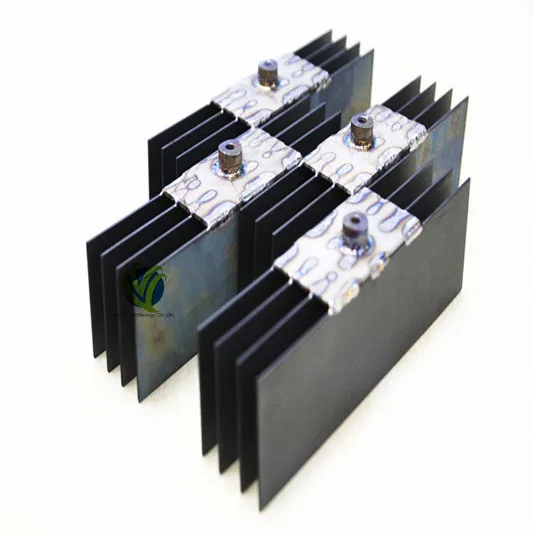

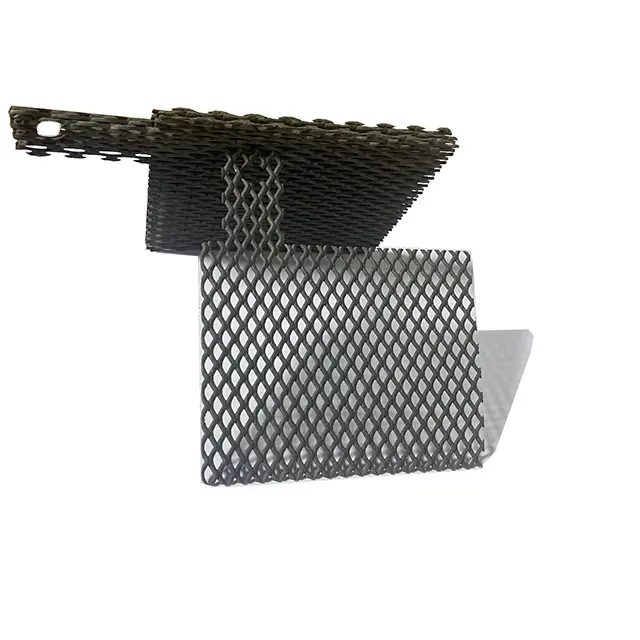

The chlorinator electrolysis cell is the one part of the whole system that actually creates chlorine in the pool. Sodium chloride or common salt dissolved into the water passes through the cell. A small amount of electric current is made to flow into a parallel set of titanium plates inside the cell. These plates, covered with a metal called iridium, separate the sodium chloride molecules through electrolysis and produce hypochlorous acid, which is the same thing produced in a non-saltwater pool when chlorine (in the form of tablets, granular, or liquid) is added to water, keeping the pool sanitized. Eventually two things will happen to the plates in the cell. The first is that the iridium coating will wear away over time and cause the cell to fail. The second issue is that these plates will accumulate scale deposits which lessen potential chlorine production.

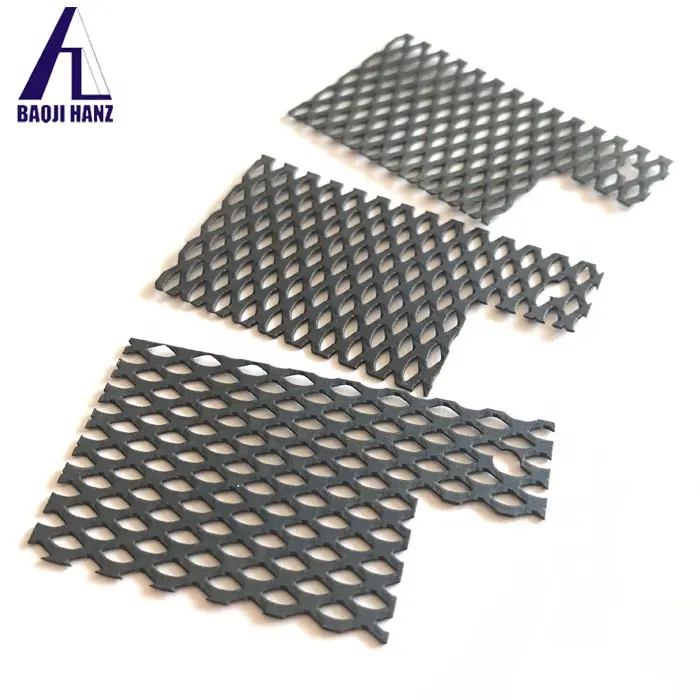

Long Life Salt Cell: The Electrochlor’s salt cell consists of a series of titanium electrodes with opposite charges. Electrochlor’s clear salt cell housing allows visual inspection of the salt cell plates and enables monitoring of chlorine production. The cell housing is constructed using clear U.V. stabilized acrylic. Both anode and cathode of the self-clean chlorinator are made from uniquely coated titanium mesh to add extra durability and life.

Low Maintenance: Electrochlor Self Clean Salt Cell has the added ability to reverse the polarity of the voltage to clean calcium buildup off its electrodes.

Brass pin connections – utilizing quick connectors for quick simple removal of the cell

Salts Level – Operation: Once an Electrochlor is installed and the desirable salt level is achieved (see table), salt needs only to be added occasionally to replace any water loss e.g. splash out, evaporation, backwashing. Salt Levels (ppm) Minimum = 4000 Optimum = 5500 Maximum = 6000 Note: Low salt level will reduce the life of the salt cell and lead to low chlorine production

Five Years Warranty:

Electrochlor Chlorinator 2 years + 3 years pro rata* Titanium cell 2 years + 3 years pro rata Power pack 2 years Commercial Installations 1 year *Please refer to Waterco’s Warranty terms and conditions

Customize the Titanium Electrodes:

Utron has a professional technical team with decades of experience on titanium electrodes, coated titanium anodes; we can design the coating according to your specific working condition. Customize the operating life as per clients’ specific needs.

Develop New Products:

UTron has excellent innovative technical engineers help you to develop new products.

Consulting and Technical Assistance:

The sales engineers and technical engineers in UTron are professional; they have intrinsic knowledge of the world of cathodic protection, waste water treatment, electroplating and electrowinning. Feel free to contact them you have any queries. They are committed to improve your processes or to solve a tricky challenge that, given certain circumstances, might have never previously existed.

OEM:

UTron can produce as per clients’needs.

Tests:

UTron can provide the Accelerated Life Test, Coating X-Ray Test, Coating Thickness Test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test and other test.

Samples:

UTron can offer free or paid samples for test.

UTron Technology is one of the leading manufacturers of titanium electrodes, coated titanium anodes and waste water treatment solution in China. It has a professional technical team and skilled workers with decades of experience in titanium electrodes and electrochemistry fields. It can offer you customize high quality titanium electrodes and perfect solutions.

Work Shop:

Our Team:

At The Fair:

Why Choose UTron?

1. Decades of titanium electrodes production experience and technical background;

2. Professional technical team and skillful workers;

3. Complete production line, from raw materials, mechanical process, surface treatment and deep processing;

4. Complete products ranges: cathodic protection titanium anodes; waste water treatment titanium electrodes; electroplating titanium electrodes; electrowinning titanium electrodes; platinized titanium electrodes, etc.

5. ISO9001: 2008, Rohs Certified;

6. Patented products;

7. Exported to 62 countries with over 2000 happy clients.

1. Can you give a quotation as per the product picture on your website?

Answer: Our anodes are non-standard products, most of them are in accordance with the requirements of the customer's specific requires. The application industries and countries are different, so please let your engineers or your customer's engineers to provide a specific size, anode working environment, usage, current density and life expectancy, so we can offer you specific price.

2. What is your internal inspection procedure, how do you inspect your products?

Answer: Re the internal inspection procedures, There are 6 steps: Material, mechanical processing, surface treatment, coating, cable connection and packing.

Every step has responsible leader, the inspector checks carefully every step with professional records, operation files, check subjects and performing programs. Once problems are checked out, steps will be taken to make up.

3. Do you have any certificate for your testes from any third party (like SGS, etc)? Or has any third party inspection company has ever tested your anodes and reported?

Answer: yes, we do have some test certificates from famous third party, like St Louis testing laboratory and china classification society etc.

4. The wooden case is too heavy; can I have other packing method such as carton box to save the freight cost?

Answer: Wooden cases are do heavy, but as per our years of export experience, carton box can make damage for the anode. Though wooden cases are heavy, but it will not damage the anode.