GG-JMS240 От 4 до 12 лет/ч арахисовое масло Обрабатывающее Оборудование для

- Категория: Станок для производства арахисового масла >>>

- Поставщик: Henan,Gelgoog,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.33 $* | 0.90 $* |

| Aug-15-2025 | 0.87 $* | 0.96 $* |

| Jul-15-2025 | 0.15 $* | 0.88 $* |

| Jun-15-2025 | 0.87 $* | 0.40 $* |

| May-15-2025 | 0.30 $* | 0.91 $* |

| Apr-15-2025 | 0.44 $* | 0.23 $* |

| Mar-15-2025 | 0.22 $* | 0.68 $* |

| Feb-15-2025 | 0.74 $* | 0.47 $* |

| Jan-15-2025 | 0.10 $* | 0.29 $* |

Характеристики

Application of Peanut Butter Processing Equipment

The peanut butter processing equipment is used for processing the raw material into super-imperceptible butter. the peanut butter processing equipment could be used for the pharmacy, food, chemical, and other materials.

Model | Capacity | Power (kw) | Dimension (mm) | Rotor diameter | Weight |

GG-JMS80 | 70-500KG/H | 4 | 680*380*930 | 80mm | 210kg |

GG-JMS110 | 300-1200KG/H | 7.5 | 750*450*1000 | 110mm | 280kg |

GG-JMS130 | 400-2000KG/H | 11/15 | 990*450*1100 | 130mm | 400kg |

GG-JMS180 | 800-6000KG/H | 18.5/22 | 1000*480*1150 | 180mm | 450kg |

GG-JMS240 | 4000-12000KG/H | 37/45 | 1330*650*1300 | 240mm | 1000kg |

GG-JMS300 | 6000-25000KG/H | 75/90 | 1450*630*1420 | 300mm | 1600kg |

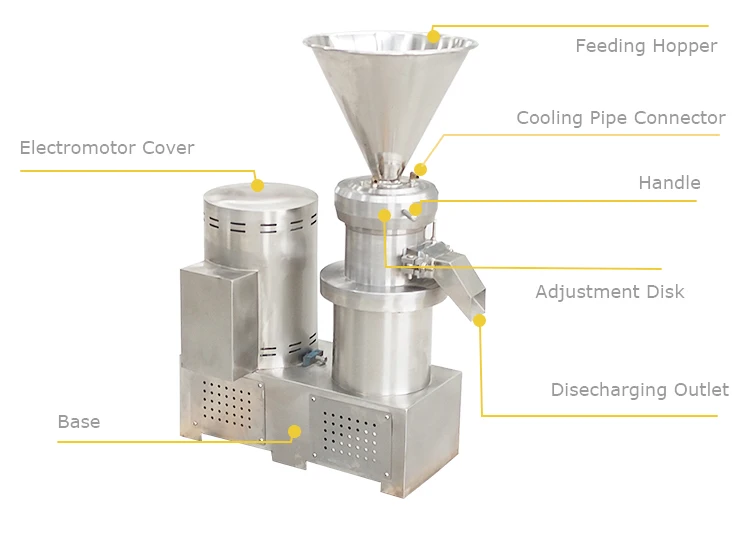

Working Principle of Peanut Butter Processing Equipment

This peanut butter processing equipment is using different shapes of stators and rotors, crushing under the high circumgyration. Grinding the material through cutting, milling, high- frequent-shaking. The distance between stators could be adjusted and grinding by recirculation.

A3: The peanut butter making machine industrial grinding nozzlecan be changed to the circulating return pipe. The circulating return pipe is provided with a three-way valve. It can be discharged or cycled as needed. All models can be changed. The 80 and 110 return pipes are 25mm in diameter, 130/. 180 return pipediameter 32mm.

Henan Gelgoog Machinery Co.,Ltd. founded in the year of 2010, is located in Zhengzhou City, Henan Province in China. We mainly engaged in producing all kinds of nuts processing machines, peanut butter making machine line and other Food Processing Machines.

Our company has many years' export experience in Machinery. We have outstanding quality control personnel as well as Trained Techinical Workers, and we have established a strong quality guarantee system. Our products are sold very well and are introduced to South-East Asia, Eastern Europe and Africa.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.