Полностью Автоматическая выдувная формовочная машина для пластиковых бутылок 20 л от

- Категория: >>>

- Поставщик: Zhangjiagang,Fillex,Beverage,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 35700.22 $* | 37485.33 $* |

| Aug-16-2025 | 35400.75 $* | 37170.85 $* |

| Jul-16-2025 | 29700.95 $* | 31185.66 $* |

| Jun-16-2025 | 34800.88 $* | 36540.83 $* |

| May-16-2025 | 30300.84 $* | 31815.88 $* |

| Apr-16-2025 | 34200.52 $* | 35910.88 $* |

| Mar-16-2025 | 33900.61 $* | 35595.70 $* |

| Feb-16-2025 | 33600.5 $* | 35280.42 $* |

| Jan-16-2025 | 33300.93 $* | 34965.23 $* |

Характеристики

Product Application

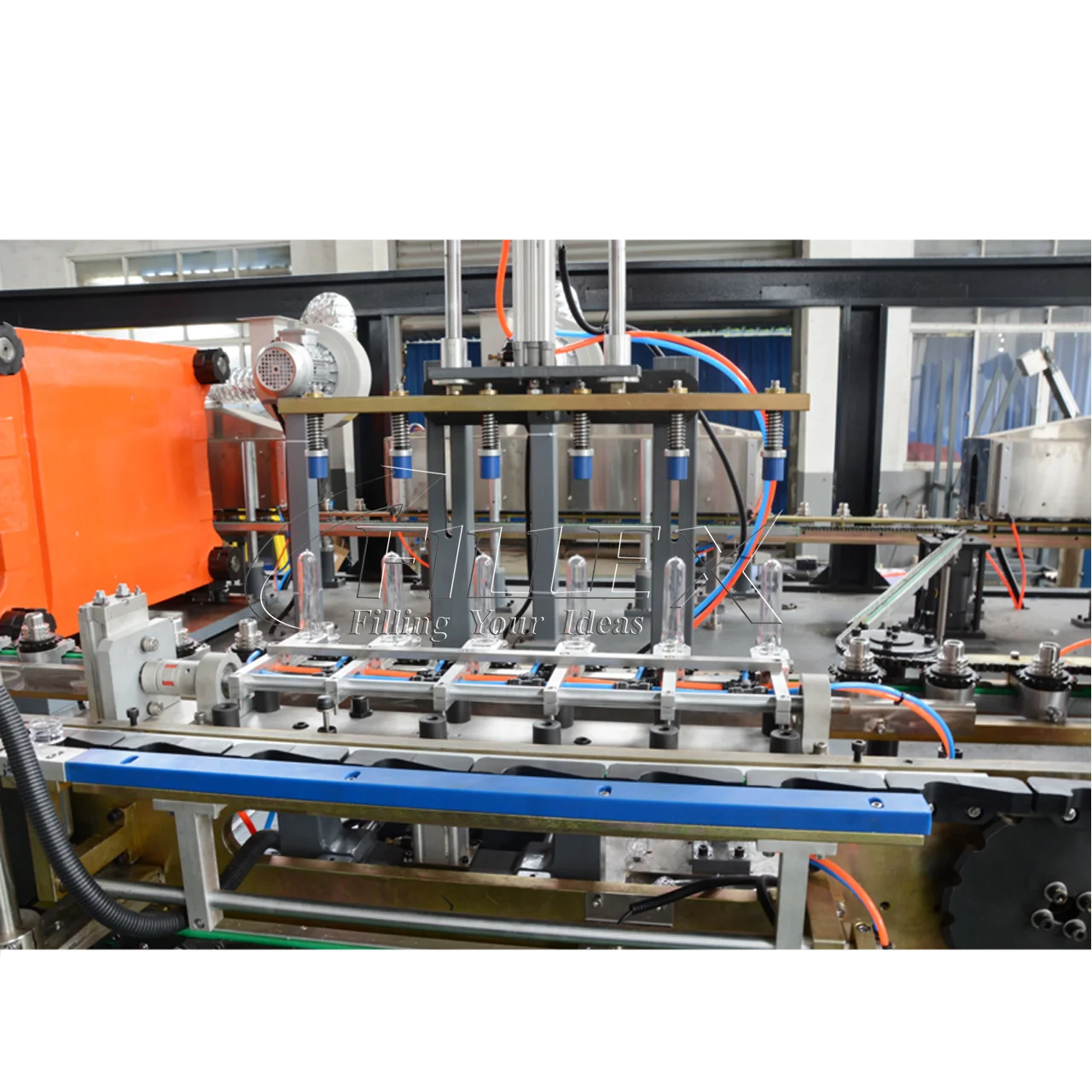

Fully Automatic 20L Plastic Bottle Blow Molding Machine Manufacturer

RBL series fully automatic rotary stretch blow molding machine ensures first-class performance which combined with a comprehensive bottle solution development program to devise the best solution for high speed. The machine features as high-tech component, stable running, less power and air consumption, minimized maintenance which could meet relevant national food sanitation requirements and shows the leading status domestically. The machine covers an extremely board range of applications including still or carbonated water, soft drinks, edible oil, juice and sport drinks, tea and milk or milk drinks.

Fillex -FBL Unit | 14KW (Water) | 16KW (Water) | 20KW (Water) | 24KW (Water) | ||

Suitable Range | Theoretical ---BPH | 20000(0.6L) | 26000(0.6L) | 33000(0.6L) | 38000(0.6L) | |

11000(1.5L) | 13000(1.5L) | 16000(1.5L) | ||||

8000(2.5L) | ---------------- | ---------------- | ||||

Plastic Resin(material) | PET-or Bio-PET | PET-or Bio-PET | PET-or Bio-PET | PET-or Bio-PET | ||

Max.Height---mm(preform) | ≤120 | ≤120 | ≤120 | ≤120 | ||

ID(neck)--mm(preform) | Φ20~25 | Φ20~25 | Φ20~25 | Φ20~25 | ||

OD(Support Ring)---mm (preform) | 33~40 | 33~40 | 33~40 | 33~40 | ||

OD(Round Shape)(Bottle) | Φ50~115 | Φ50~90 | Φ50~90 | Φ50~90 | ||

Diagonal(Square Shape) (Bottle) | 60~115 | 60~92 | 60~92 | 60~92 | ||

Height(Under Support Ring)(Bottle ) | ≤332 | ≤320 | ≤320 | ≤320 | ||

Max.Height(ml)(Bottle ) | ≤2500 | ≤1500 | ≤1500 | ≤1500 | ||

Main Features

*It adopts the high definition TFT touch scream display, which can easily make the languages conversion and give the operation order through multi-level menu with pictures and text mode. The production speed, shift production, technical parameters and etc are displayed in the different level menus, which has a good man/machine interface while it is convenient for the operation.

*It adopts the special design of the after-blowing system, which can inspect the pressure curve during bottle molding and provide the on-line parameters for the technical adjustment .It saves work to adjust the technical parameters and also ensures that bottle molding is stable.

*The heater adopts the nine -section far infrared temperature control; each group of lamp in the heating light preheating area and adjusting area is respectively controlled according to the technics .There is an on-line temperature detection system, which ensure the technical accuracy and stability.

*Technical parameters such as preform, heating temperature, blowing time and etc can be prefixed when changing the bottle preform and bottle shape .Thus production runs normally.

*Air pipe part is equipped with exhaust air recycle system, save 20-30% consumption, reduce the cost.

*Equip the imported lubrication system; machine can do the lubrication itself, which reduces the labor.

*Blow molding adopts the special aluminum alloy, the surface is oxidized treated .It has a long life use, which reduce the production cost.

*It' s equipped with the safety door alarm system ,ensuring the operator safety .

Water Filling Machine

91.8% Response Rate

OPP Labeling Machine

91.8% Response Rate

Shrink Wrapping Machine

91.8% Response Rate