Автоматическая кривая ПВХ кромкооблицовочная машина для обработки древесины с предварительной

- Категория: Wood Based Panels Machinery >>>

- Поставщик: Jinan,Goodcut,Cnc,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.97 $* | 0.56 $* |

| Aug-19-2025 | 0.39 $* | 0.83 $* |

| Jul-19-2025 | 0.43 $* | 0.4 $* |

| Jun-19-2025 | 0.28 $* | 0.53 $* |

| May-19-2025 | 0.48 $* | 0.14 $* |

| Apr-19-2025 | 0.84 $* | 0.25 $* |

| Mar-19-2025 | 0.78 $* | 0.15 $* |

| Feb-19-2025 | 0.11 $* | 0.56 $* |

| Jan-19-2025 | 0.27 $* | 0.84 $* |

Характеристики

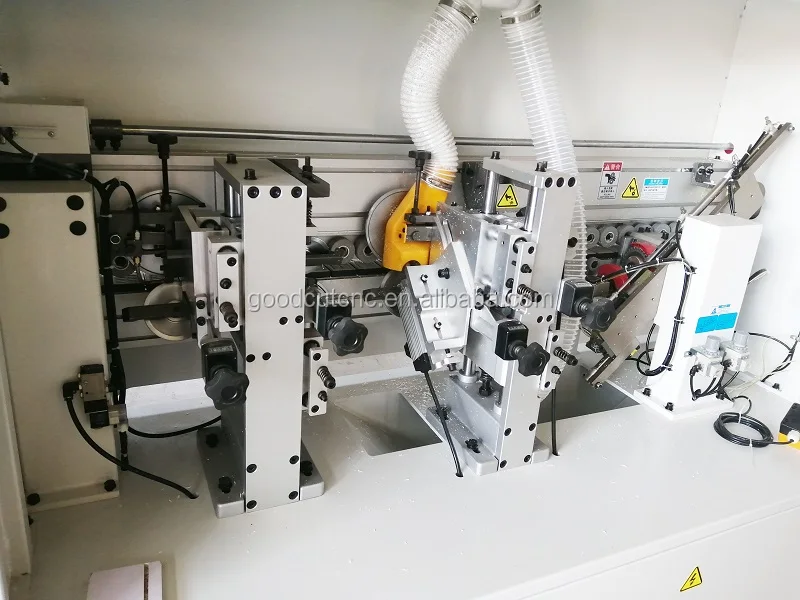

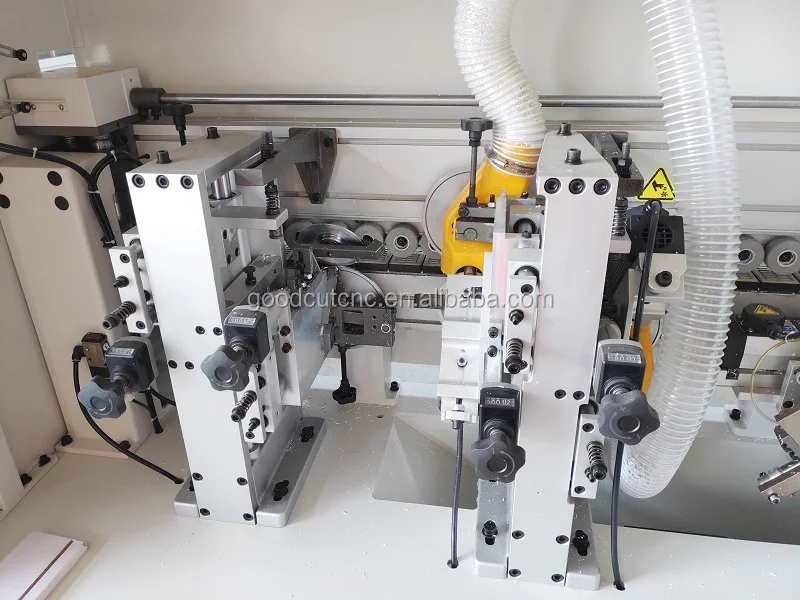

Auto curve pvc wood edge bander machine for wood working with pre milling

Production Description:

Edge Banding machine work is a process and an associated narrow strip of material used to create durable and aesthetically pleasing trim edges during finish carpentry. Edge banding is used to cover the exposed sides of materials such as plywood, particle board or MDF, increasing durability and giving the appearance of a solid or more valuable material. Common substitutes for edge banding include face frames or molding. Edge banding can be made of different materials including PVC, ABS, acrylic, melamine, wood or wood veneer.

Traditional edge banding was a manual process requiring ordinary carpentry tools and materials. In modern applications, particularly for high-volume, repetitive manufacturing steps such as cabinet doors, edge banding is applied to the substrate by an automated process using a hot-melt adhesive.

Because of the needs of the market, automatic edge banding machines were used in wood products processing widely.

Model | HC469JC |

Electrical Lift | Yes |

Motor Power | 19kw |

Overall size(L*W*H) | 9200*1000*1900mm |

Feed Speed | 0-28m/min |

Panel Width | ≥60mm |

Panel Thickness | 10~60mm |

Edge Tape Width | 15~65mm |

Edge Tape Thickness | 0.4-3mm |

Features:

1. Through special structure, the edge-sealing sheet and the edge-sealing material are evenly coated and pressed, so that the edge-sealing strip is more firmly attached.

2. Through the precision linear guide motion, the rapid cutting structure of the high-frequency high-speed motor is automatically tracked by the master to ensure that the cut surface is smooth and smooth.

3, using the model automatic tracking and high-frequency high-speed motor structure, repair the excess edge banding material on the edge of the board edge strip.

4, used to eliminate the ripples caused by the cutting process of trimming non-linear motion.

5. Clean the finished plate with a cotton polishing wheel and smooth the edge of the edge by polishing

Advantage:

1.Adopt domestic famous motor and high quality electrical components.

2.The fuselage is firm and steady,thus increasing the stability of the whole machine.

3.Aluminum alloy beam is a relatively advanced method, its precision and straightness are far

superior to cast iron.

4.Auto cleaning, high precision, high efficiency.

5.The machine can be customized.

6.Automatic and precise gluing procedure as well integrated double finishing side within one workflow .The end cutting can be done at the rear side of the machine.

7.Multiple Air cylinder will assembled on the machine, mainly used for positioned location assured the panel materials processing accuracy in a very high level.

8.Secondary Dust Exhaust System, mainly used for sawdust collection during processing period, to keep the material smooth and clean.

9.The machine adopts the devices of sound insulation, controlling of dust, platform frame Micro adjustment by manual operation.

Product Application:

Edge banding machine in woodworking is used in banding edge of desks,carbinet,wardrobe and stright line furniture.The edge bander can be PVC,melamine,wood based works and so on,with powerful fuctions as edge feeding,sticking,material cutting,front-back trimming,roughing,fine finishing,scraping and buffing,with features as follows:

1) Adopt high-power and high frequency motor to improve effect

2)The pressure beam is made of high strength aluminum alloy heavy structure, which makes the material more stable and efficient during operation.

3)The imported trachea has high flexibility, winter frost resistance, no burst, frost resistance, fatigue resistant cable and more extended service life.

4) The frame plate, cold plate welding, after welding after annealing processing, the machine in the production process without affecting the internal stress and deformation.

The machine is guaranteed for 12 months .Within 12 months under normal using and maintenance, if the machine has something problem ,you will get spare part for free . more than 12 months,you will get the cost price for accessories. You will also get technical support and service all the time.

Payment:

1)Sample payment by T/T,Paypal,Western Union,MoneyGram,Alipay

2)Large quantity payment by T/T