Плазменный ионизирующий генератор для клубники и

- Категория: Другое оборудование для очистки воздуха >>>

- Поставщик: Shenzhen,Lideng,Environmental,Protection,Engineering,Co.,Ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-18-2025 | 48475.78 $* | 49445.96 $* |

| Jul-18-2025 | 39314.16 $* | 40100.6 $* |

| Jun-18-2025 | 47711.35 $* | 48665.85 $* |

| May-18-2025 | 47330.13 $* | 48277.98 $* |

| Apr-18-2025 | 37787.77 $* | 38543.84 $* |

| Mar-18-2025 | 46566.34 $* | 47497.87 $* |

| Feb-18-2025 | 46184.98 $* | 47108.47 $* |

| Jan-18-2025 | 45803.6 $* | 46719.92 $* |

Характеристики

Product Description

Disinfection and sterilization in food production, processing and storage is an important issue that enterprises must address. However, with the development of society and the progress of science and technology, the disadvantages of traditional disinfection methods are gradually revealed. Traditional methods are often incomplete disinfection, there are dead ends, the disinfection effect decays quickly, can not realize the human-computer coexistence, and is ineffective for certain bacteria in a specific environment.

1. Central air-conditioning disinfection in production workshop

Although the central air conditioning in food production workshops has filtered the air, many microorganisms such as staphylococci, bacilli, molds and various viruses are still present in the air for various reasons. Food products are directly exposed to the air, so it is extremely important to keep the air clean and sanitized. Chemical spraying or fumigation methods may contaminate the foodstuffs, while traditional UV lamps and ozone sterilization methods have great limitations in terms of space and time of use, and can cause severe oxidation of production equipment in the workshop when used for long periods of time.

Plasma air treatment technology can be a very effective solution to the daily sterilization and disinfection problems of large space processing workshops. It has the ability of broad-spectrum sterilization, high elimination efficiency, and can reduce the concentration of bacteria, viruses and odors in a short period of time. Plasma technology can kill in all directions, without dead-end restrictions, and can realize the coexistence of man and machine, safe and no secondary pollution, does not affect the production, and does not require special management. The equipment is pollution-free, without consumables, with cost savings and high efficiency and environmental protection advantages.

2. Cleaning and sterilization of food materials

Food raw materials (such as fresh meat, thawed meat, fresh aquatic products, vegetables and fruits directly from the ground, etc.) usually carry a large number of bacteria, viruses and fungi, so they must be cleaned and sterilized before processing. Plasma-activated water can significantly reduce or completely eliminate all kinds of microorganisms on the surface of raw materials in a short period of time, and it can also degrade pesticide and fertilizer residues in fruit and vegetable raw materials.

In the process of livestock and poultry slaughtering, the use of plasma-activated water to clean carcasses, viscera, personnel's hands, tools and the ground, not only can kill bacteria, but also effectively remove odors and improve the environment of the slaughterhouse. The concentration of plasma activated water needs to be determined according to the time and scene of use.

1. Central air-conditioning disinfection in production workshop

Although the central air conditioning in food production workshops has filtered the air, many microorganisms such as staphylococci, bacilli, molds and various viruses are still present in the air for various reasons. Food products are directly exposed to the air, so it is extremely important to keep the air clean and sanitized. Chemical spraying or fumigation methods may contaminate the foodstuffs, while traditional UV lamps and ozone sterilization methods have great limitations in terms of space and time of use, and can cause severe oxidation of production equipment in the workshop when used for long periods of time.

Plasma air treatment technology can be a very effective solution to the daily sterilization and disinfection problems of large space processing workshops. It has the ability of broad-spectrum sterilization, high elimination efficiency, and can reduce the concentration of bacteria, viruses and odors in a short period of time. Plasma technology can kill in all directions, without dead-end restrictions, and can realize the coexistence of man and machine, safe and no secondary pollution, does not affect the production, and does not require special management. The equipment is pollution-free, without consumables, with cost savings and high efficiency and environmental protection advantages.

2. Cleaning and sterilization of food materials

Food raw materials (such as fresh meat, thawed meat, fresh aquatic products, vegetables and fruits directly from the ground, etc.) usually carry a large number of bacteria, viruses and fungi, so they must be cleaned and sterilized before processing. Plasma-activated water can significantly reduce or completely eliminate all kinds of microorganisms on the surface of raw materials in a short period of time, and it can also degrade pesticide and fertilizer residues in fruit and vegetable raw materials.

In the process of livestock and poultry slaughtering, the use of plasma-activated water to clean carcasses, viscera, personnel's hands, tools and the ground, not only can kill bacteria, but also effectively remove odors and improve the environment of the slaughterhouse. The concentration of plasma activated water needs to be determined according to the time and scene of use.

3. Disinfection of material storage (cold storage)

Plasma-activated water can be used to thoroughly clean and disinfect floors, walls, shelves and holding bins in empty warehouses. The plasma air sterilization system can effectively inhibit the growth of various microorganisms in the warehouse and kill various airborne germs in time to prevent mold and decay of food.

For cold storage with exposed food, the plasma air sterilization system can be operated 24 hours a day, realizing the coexistence of man and machine.

Plasma-activated water can be used to thoroughly clean and disinfect floors, walls, shelves and holding bins in empty warehouses. The plasma air sterilization system can effectively inhibit the growth of various microorganisms in the warehouse and kill various airborne germs in time to prevent mold and decay of food.

For cold storage with exposed food, the plasma air sterilization system can be operated 24 hours a day, realizing the coexistence of man and machine.

Why Choose Us

Choosing our plasma air purifier means choosing leading technology and superior quality. We are committed to providing state-of-the-art air purification solutions helping companies to improve product quality and enhance market competitiveness.

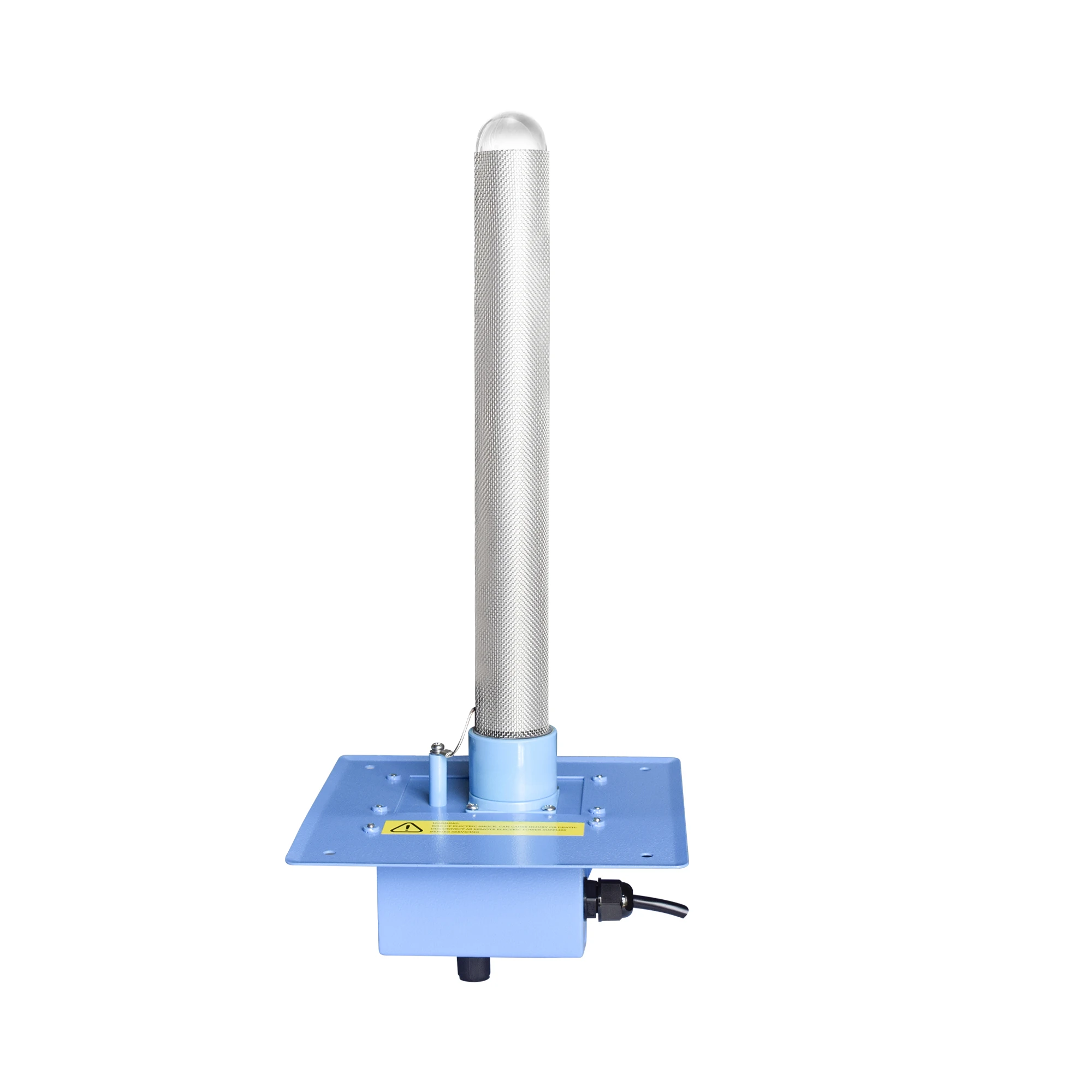

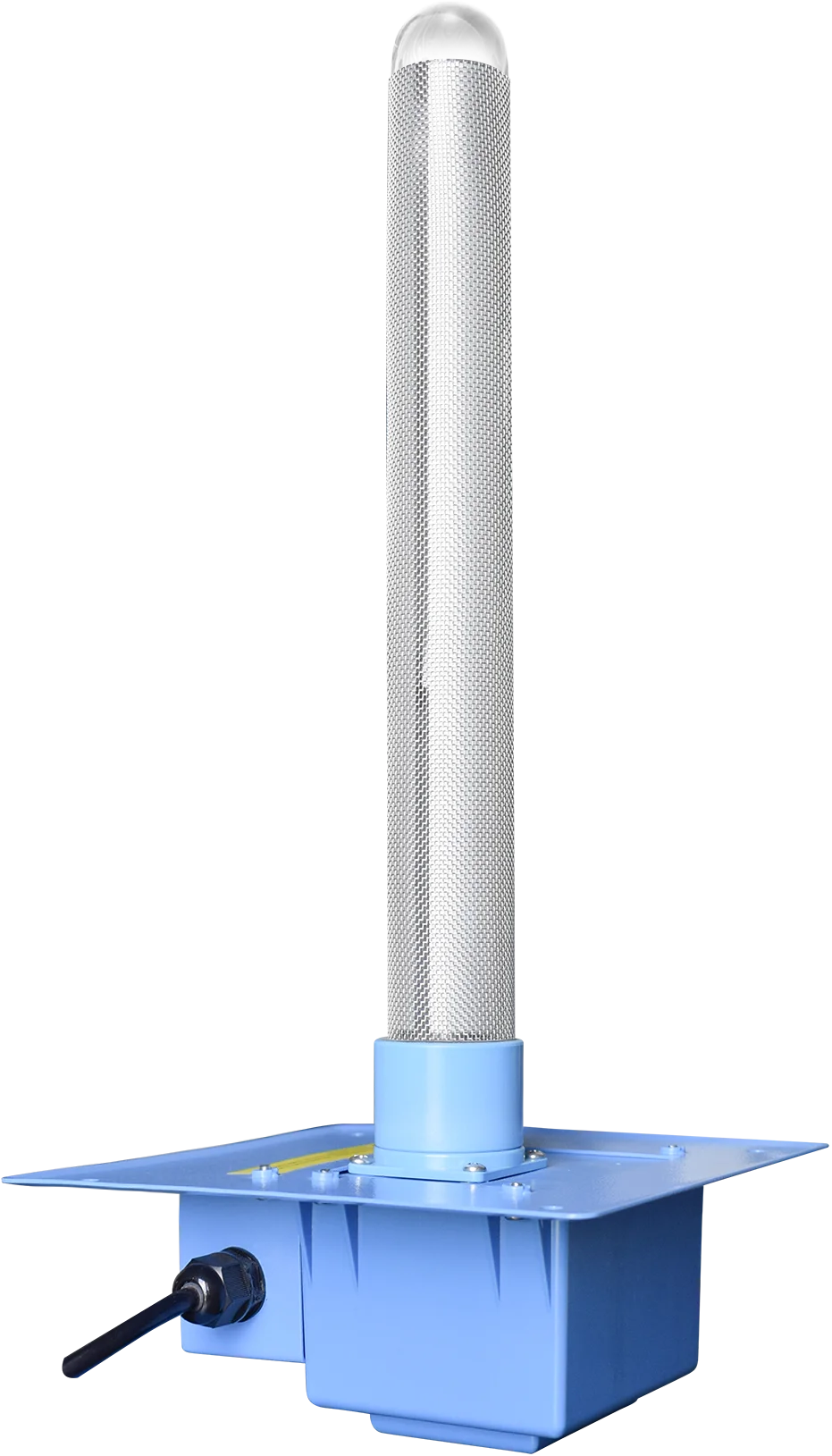

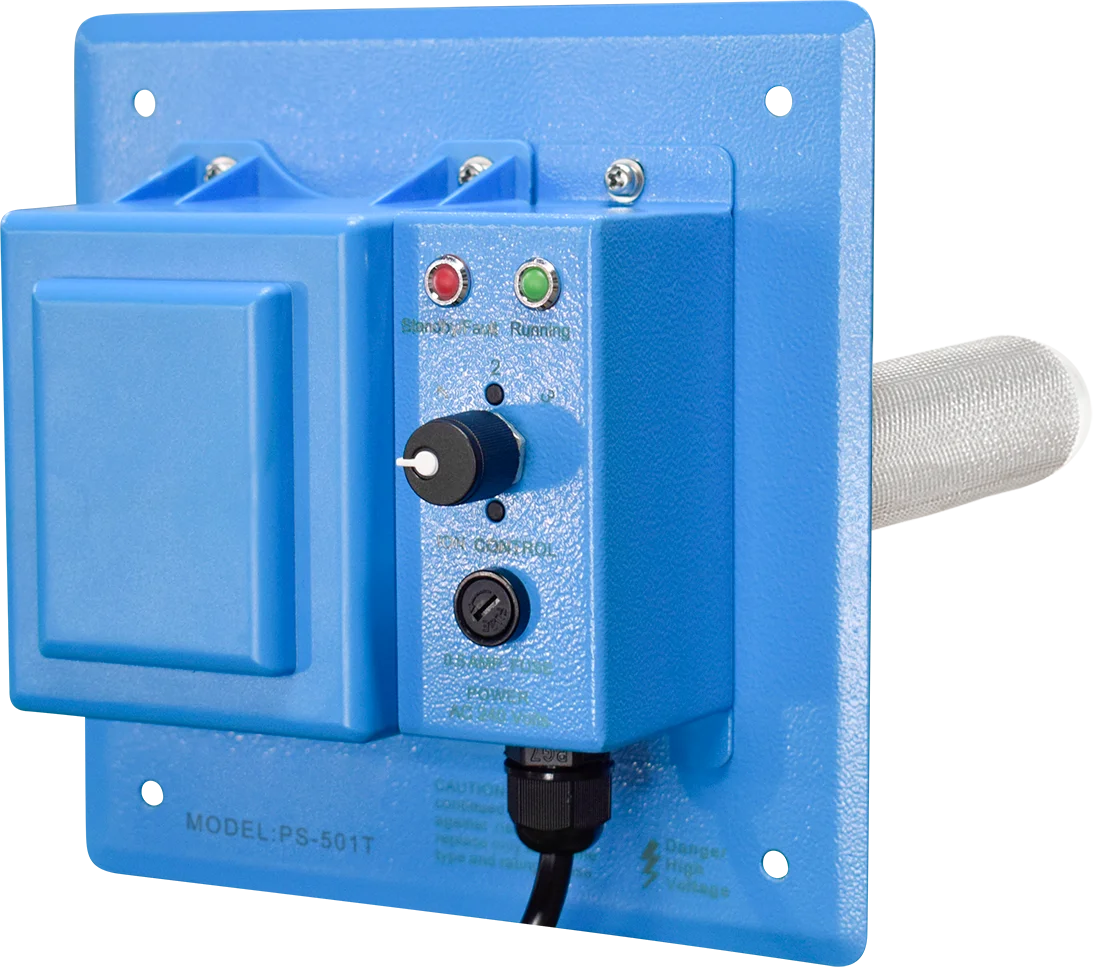

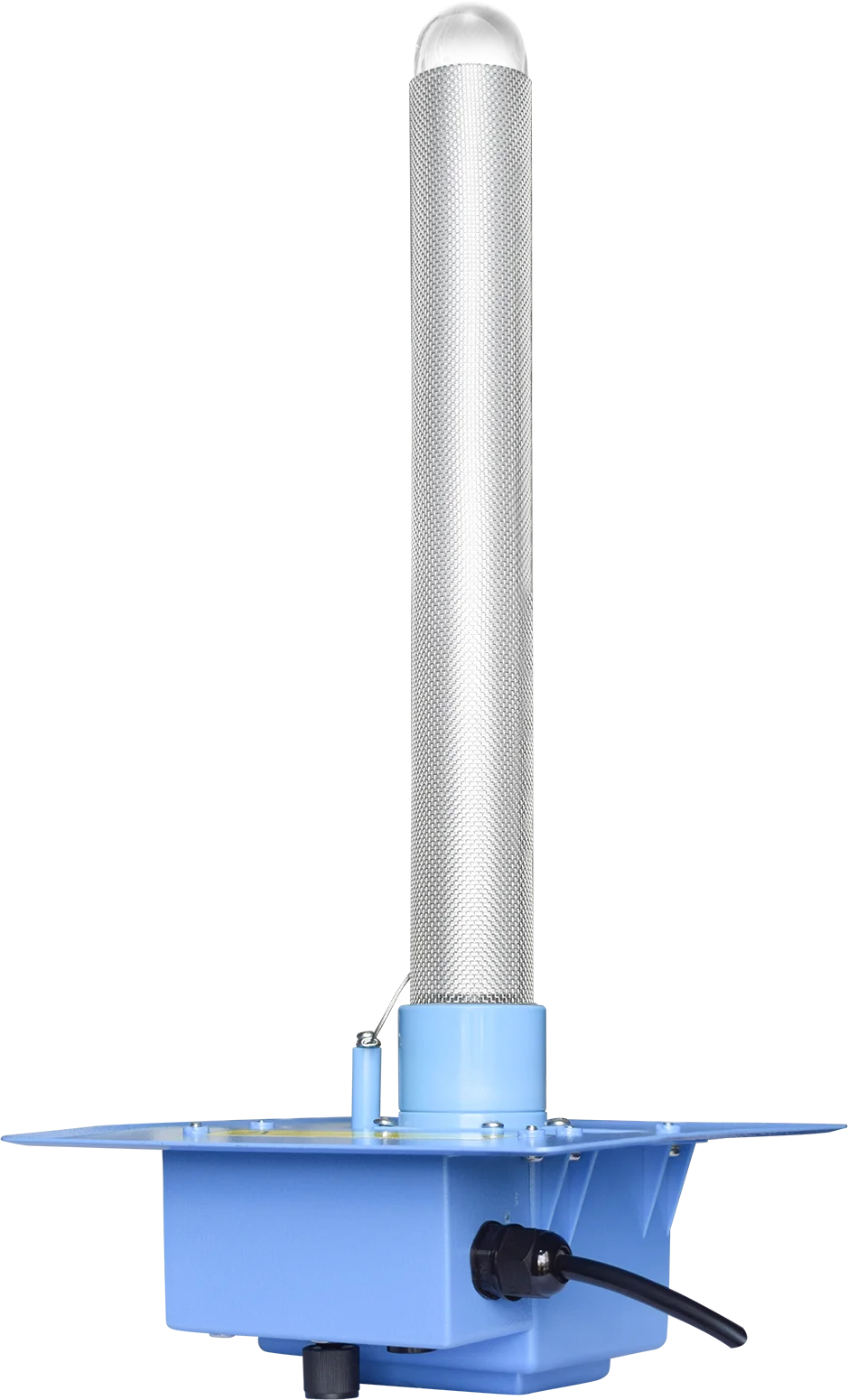

Product specification

Brand | Edda Air |

Model | PS-50T1 |

Air Volume | 1800CFM~3100m³/h |

Weight | 2.85/1kg |

Voltage | 12V DC |

Dimensions | 192*192*430mm |

Voltage | 120V AC / 240V AC |

Frequency | 50Hz |

Shell Material | SPCC+ABS |

Applicable Area | 100m² |

Noise | <20dB |

Number of Ion Tubes | 1pcs |

Ion Tube Size | 350mm(14.0 inch) |

Ion Tube Lifespan | 17000 Hours |

Application Scenario | suitable for use in Office Building, School, Hospital, Clinic, Construction, Hotel, Farm, Transportation, growing room Warehouse, cold storage etc. |

Company Information

Eddaair Air bipolar ionization technology is installed in thousands of commercial, institutional, residential and industrial

buildings around the world. For over a decade, we've been providing safe, effective air purification solutions for schools,

commercial buildings, and single- and multi-family homes.

buildings around the world. For over a decade, we've been providing safe, effective air purification solutions for schools,

commercial buildings, and single- and multi-family homes.

Cost Advantage

Eddaair is located in Shenzhen, Guangdong Province, with a complete industrial chain, a high degree of industrial

intensification, low labor cost and convenient transportation. The cost of production parts and hardware processing that need to be purchased is relatively low, resulting in a highly competitive cost of finished products.

intensification, low labor cost and convenient transportation. The cost of production parts and hardware processing that need to be purchased is relatively low, resulting in a highly competitive cost of finished products.

Product Advantages

Eddaair has a total of 5 series, in addition to the In duct series, Eddaair in order to meet customer needs, to meet the different installation needs of customers, we also developed ceiling mounted, wall mounted, movable series and portable series of products.

Technical Advantages

Benefits of Bipolar Ionisation Technology :

1.Eliminates odours, smoke and chemicals.

2.Reduces bacteria, viruses and mould.

3.Suitable for industrial and commercial applications.

3.Suitable for industrial and commercial applications.

4.Completely automated and chemical free.

5.Easy to install.

6.Can operate as a standalone or integrated solution.

Our Services

FAQ

Q 1: How can I get a price?

A: We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote

Q 2: Can I buy samples placing orders?

A: Yes. Please feel free to contact us

Q 3: What is your lead time?A: It depends on the order quantity and the season you place the order. Usually we can ship within7-15 days for small quantity, and about 30 days for large quantity

Q 4: What is your payment term?

A: T/T, Western Union, L/C, and Paypal. We can negotiable.

Q 5: What is the shipping method?

A: It could be shipped by sea, by air or by express(EMS, UPS, DHL, TNT, FEDEX and ect). Please confirm with us before placing orders.

A: We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote

Q 2: Can I buy samples placing orders?

A: Yes. Please feel free to contact us

Q 3: What is your lead time?A: It depends on the order quantity and the season you place the order. Usually we can ship within7-15 days for small quantity, and about 30 days for large quantity

Q 4: What is your payment term?

A: T/T, Western Union, L/C, and Paypal. We can negotiable.

Q 5: What is the shipping method?

A: It could be shipped by sea, by air or by express(EMS, UPS, DHL, TNT, FEDEX and ect). Please confirm with us before placing orders.

The EddaAir Mission:

Make Grow Sourcing Easy (and Fun)

We understand the challenges of maintaining clean and sterile air in various environments. That's why we've created a destination that makes ordering air purification and sterilization supplies easy and hassle-free.

Our on-site chat and prompt customer service ensure that your questions and concerns are always addressed. We look forward to serving you today!