Подойдет как для повседневной носки так доза пластиковая бутылка формовочная машина наполнения и запечатывания оливковое масло GGS-240

- Категория: Pharmaceutical Filling Machine >>>

- Поставщик: Hunan,Grand,International,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.7 $* | 0.71 $* |

| Aug-18-2025 | 0.75 $* | 0.90 $* |

| Jul-18-2025 | 0.30 $* | 0.89 $* |

| Jun-18-2025 | 0.10 $* | 0.23 $* |

| May-18-2025 | 0.59 $* | 0.24 $* |

| Apr-18-2025 | 0.86 $* | 0.66 $* |

| Mar-18-2025 | 0.57 $* | 0.50 $* |

| Feb-18-2025 | 0.85 $* | 0.55 $* |

| Jan-18-2025 | 0.81 $* | 0.25 $* |

Характеристики

Mono Dose Plastic Bottle Forming Filling Sealing Machine Olive Oil GGS-240 P5

| Product Name | Mono Dose Plastic Bottle Forming Filling Sealing Machine Olive Oil GGS-240 P5 | ||||

| Model | GGS-118 P2 (2 filling heads) | GGS-118 P5 (5 filling heads) | GGS-240 P5 (5 filling heads) | GGS-240 P10 (10 filling heads) | GGS-240 P15 (15 filling heads) |

| Max. Forming Depth | 12mm | ||||

| Cutting Speed | 0-25 times/min | ||||

| Filling Volume | 0.8-200ml | ||||

| Packing Material | PVC/PE, PET/PE, PVC/EVOH combined sheet (thickness: 0.2-0.4mm) | ||||

| Power Supply | 3.5KW | 4.5KW | 6.5KW | 22KW | 22KW |

| Voltage | 220V/380V 50HZ (can be customized) | 380V 50HZ (can be customized) | |||

| Machine Dimension | 1800*800*1400mm | 2300*850*1500mm | 3200*850*1400mm | 5200*850*1600mm | 7300*1050*1800mm |

| Machine Weight | 550KG | 750KG | 1200KG | 2200KG | 3000KG |

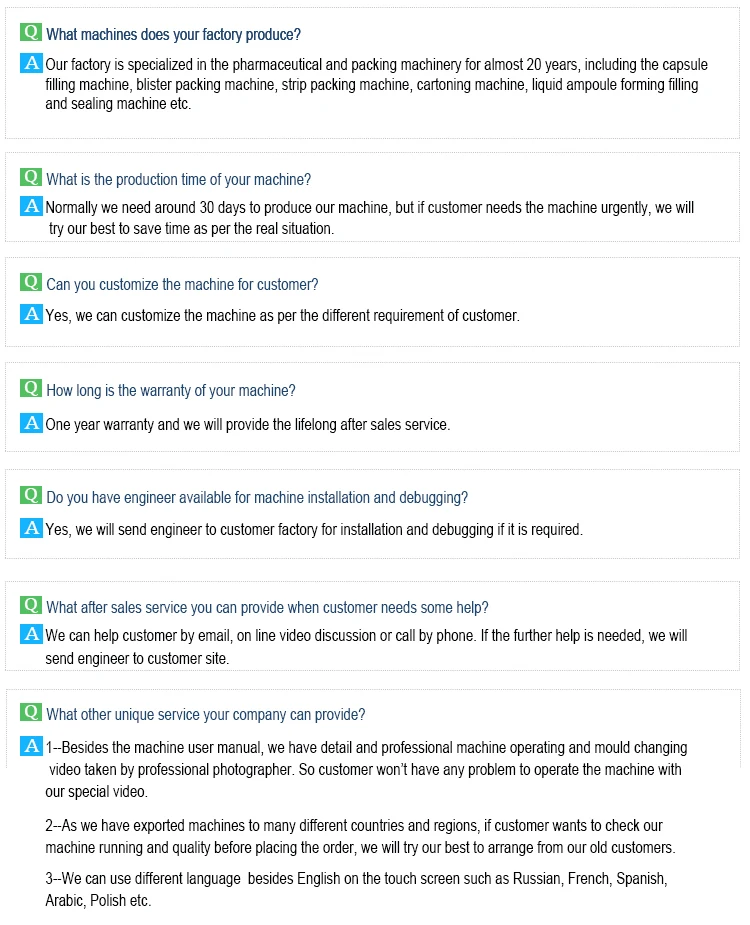

This machine is a kind of compact type liquid filling and sealing machine, it is suitable for small batch filling for different product and widely used for filling oral liquid, perfume, liquid, essential oil, olive oil, health care product etc. in pharmaceutical, herbal, pesticide, cosmetic, food and supplement area.

Performance and Features

1. The machine adopts PLC control and stepless altering frequency adjustment.

Service 1

Providing photographer recording high precision video about installing, debugging and changing mould for you before shipment, cost paid by ourselves. The video helps you operate the machine better, which not provided by other suppliers.

Service 2

Different languages are available to be inputted in the touch screen, such as Russian, Arabic, French, Spanish etc., in order to help your machine operator understand and run machine smoothly.

Service 3

We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4

12 (twelve) months guarantee time. During this Warranty period, we will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice. We will also provide one set of spare parts/wear & tear parts to customer along with the shipment of the machine.

Service 5

Warmly welcome suggestions from customer, to help us grow better and provide much better machines. Meanwhile, welcome to have a visit or inspection the machine before order or shipping. We'll arrange the pick up and your following schedule in our city to bring you a nice journey.

Hunan Grand Packing Machinery Co., Ltd.

We're specialized in the pharmaceutical and packing machiney for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc..

Our machines were exported to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea, the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago, Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. Good reputation of the machine quality and after sales service always gained from customers. Various kinds of factories and companies in different fields are cooperating with us. Such as pharmaceutical, food , supplement, stationery, hardware, agrochemical factories. For pesticide, fertilizer, personal care products, like cosmetics, daily use products etc..

Our sales team are professional in communicating with customer about different aspects of our machines. We also have our own technical research group to do the new products development and professional group for customer overseas after sales service . For customer who doesn’t need our enginner for machine installation, we will provide them the detail and professional machine installation and running video for support and help.

Welcome to get in touch with us, we are always here for you...