Лазерная Сварка/Резка/Покраска/сборка Роботизированный

- Категория: Manipulator >>>

- Поставщик: Wuhan,Questt,Asia,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 18921.75 $* | 19867.58 $* |

| Aug-17-2025 | 18762.88 $* | 19700.25 $* |

| Jul-17-2025 | 15741.74 $* | 16528.36 $* |

| Jun-17-2025 | 18444.80 $* | 19366.42 $* |

| May-17-2025 | 16059.67 $* | 16862.38 $* |

| Apr-17-2025 | 18126.48 $* | 19032.24 $* |

| Mar-17-2025 | 17967.37 $* | 18865.42 $* |

| Feb-17-2025 | 17808.37 $* | 18698.73 $* |

| Jan-17-2025 | 17649.55 $* | 18531.69 $* |

Характеристики

Laser Welding/Cutting/Painting/Assembly Robot Arm

How to make robot systems replace workers and save cost?

Wuhan Questt Aisa Technology is a manufacturer that specialized in producing laser machines, especially committed to the production of standard and non-standard fully automated or semi-automatic laser systems with robot assistance. For example: 3D welding robot, 3D cutting machine, automatic positioning painting, laser cladding machine, automatic laser cleaning machine, etc. So we have multiple robots. We can offer you a single robot or a compele robotic system, distrubutors are also welcome!

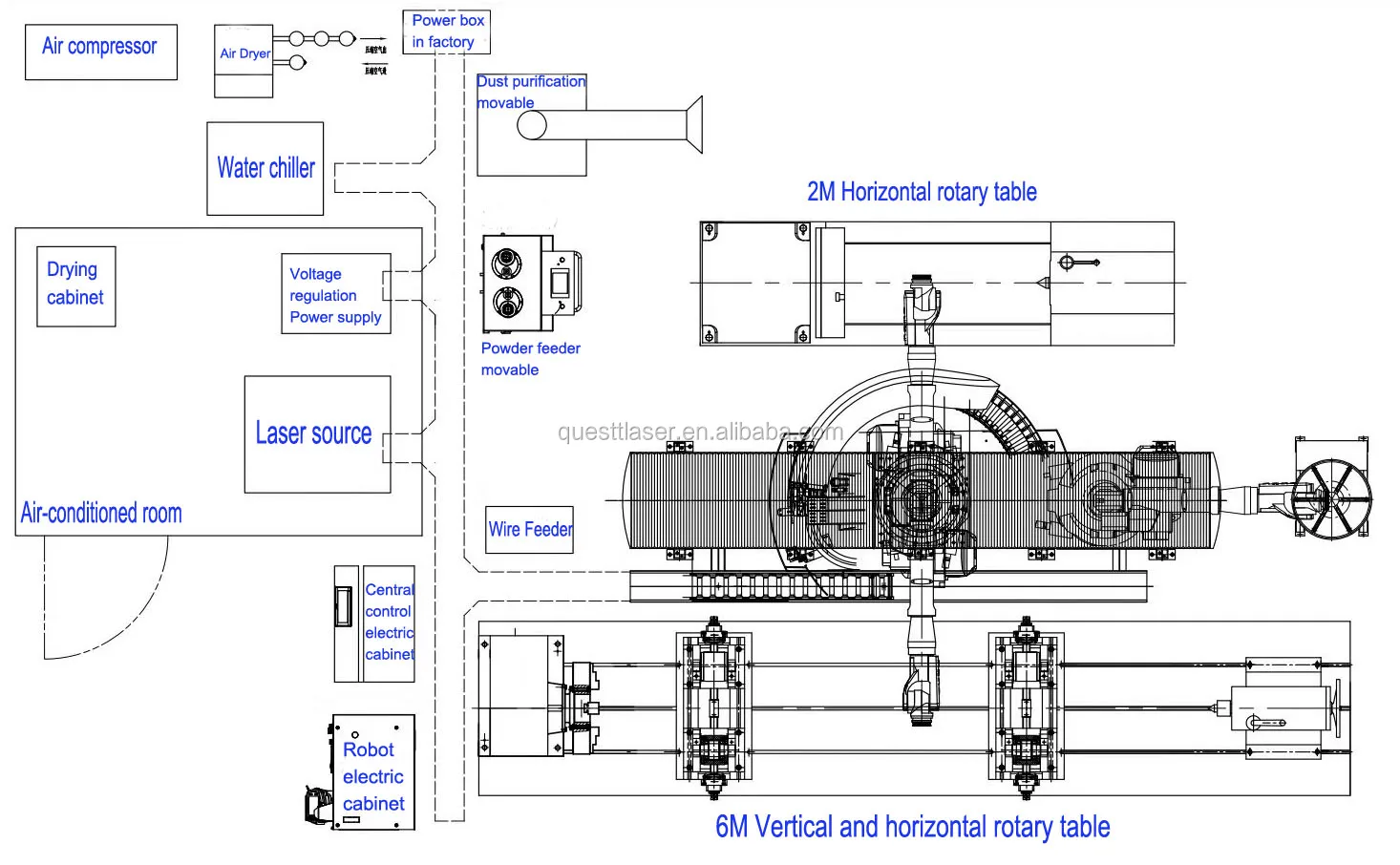

This is a laser cladding machine, we put our robot in this project. The brand for this robot can be ABB, EPSON, STEP etc. So the price varies on different demands from customers, but it's always very cost-effective.

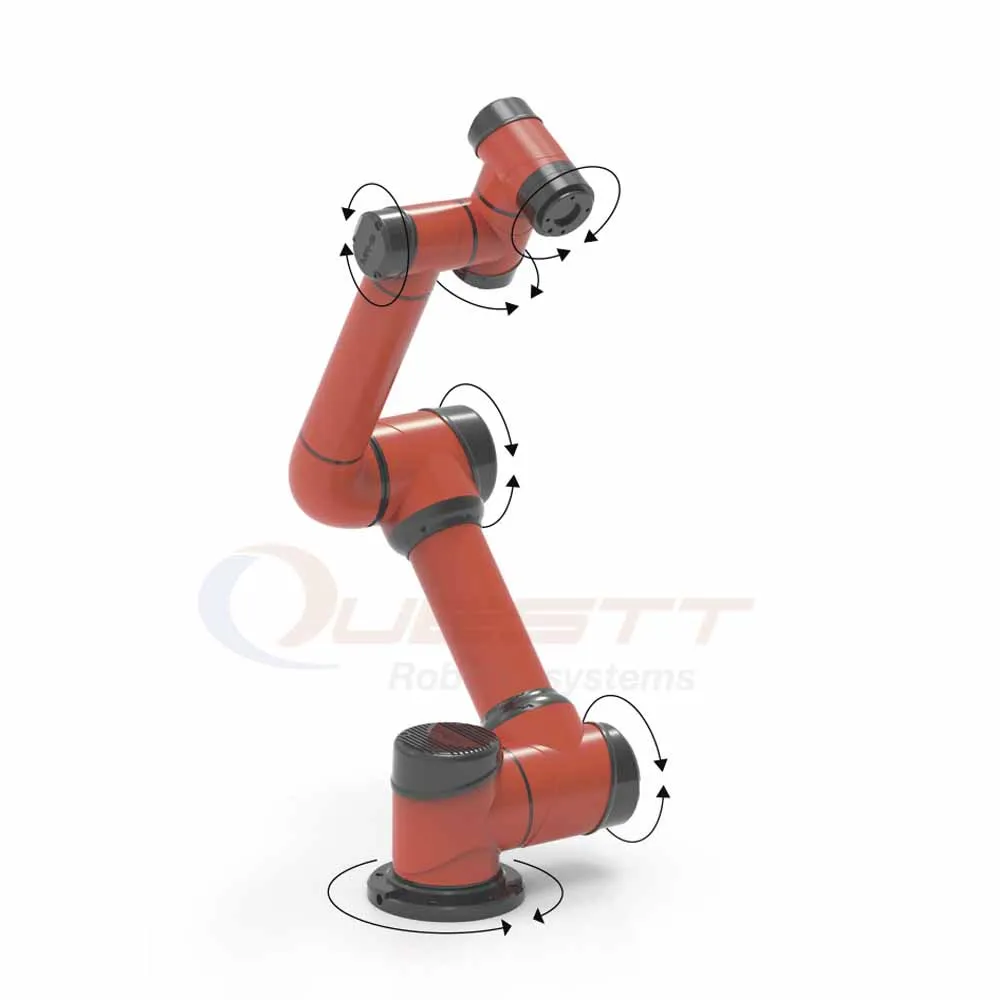

This is the laser welding robot arm

This is a CNC arm robot

Bellows are the introduction of our robot with few types, please contact us to get more series and functions.

Payload:6kgs, 20kgs, 50kgs etc.

Horizontal reach:1,405mm-2,291mm

Vertical reach:2,384-3,389mm

Repeatibility: ±0.05 mm

Weight: 74kgs,140kgs, 246kgs, 510kgs.

Kika series robot with different functions: In this page we only list Model-MR1400, a small model for your reference, if you need more models with other functions, please feel free to contact us.

KiKA robotic system MR1400 model is especially designed for Mig/Mag welding, which has high efficiency.

This series robot Small size light weight, is dedicated to arc welding robot, can realize the stable welding, obtain high precision welding path, shorten the welding cycle, extend the life of the pipe and cable At the same time SA series welding robot can flexible welding operations within the narrow space, can easily choose the ground installation mount inversion

Technical Parameters

| Model | MR1400 | |

| Payload | 6 KGS | |

| Max Working Radius | 1405 mm | |

| Arm Length | 2391 mm | |

| Number of Axis | 6 | |

Max speed | Axis1 | 150 °/S |

| Axis2 | 150 °/S | |

| Axis3 | 160 °/S | |

| Axis4 | 360 °/S | |

| Axis5 | 320 °/S | |

| Axis6 | 360 °/S | |

Max Operation Area | Axis1 | ±165° |

| Axis2 | +155° ~ -90° | |

| Axis3 | +70° ~ -200° | |

| Axis4 | ±170° | |

| Axis5 | ±120° | |

| Axis6 | ±360° | |

| Max moment Allowable Torque | Axis5 | 54 NM |

| Axis6 | 23 NM | |

| Weight | 140kg | |

| Position Repeatability | 0.05mm | |

| Working temperature | 0-45 ℃ | |

MR1400 Robotic Arm Standard Configuration List | |||

Control System | SMR1000 Controller + STEP Series Servo Driver | ||

Item No. | MR1400 | ||

Servo Motor Brand | TAMAGAWA MOTOR | ||

Length of power line | 5M | ||

Length of encoder lines | 5M | ||

Length of power supply line | 5M | ||

The teaching machine brand | Keba/SRTP1000 | ||

Length of teaching machine line | 5M | ||

Communication | Category | Name | Specifications |

Bus | EtherCAT bus | 1 piece | |

CANopen | 1 piece | ||

RS232/RS485 | 1 piece | ||

IO | digital input DI (Weidmuller) | 1 piece(16 road) | |

digital output DO (Weidmuller) | 1 piece(16 road) | ||

Others | Ethernet Standard Ethernet interface | 1 piece | |

Accessories | CD(Software, Project, electronic user manual) | ||

Remark | |||

Advantages

Applications

Kika COMPACT robots are ideal for small parts assembly , dispensing , lab automation , medical device assembly , machine tending , material handling , packaging, electronics and many other applications.

This type is specially designed for Mig/Mag weldting industry.

Payload:5kgs

Arm length:924mm

Number of axis: 6 axis

MR5 OPTIMAS series robot adopts the fully modular design and uses system towards developers. The MR5 is a collaborative robot. It has two important functions: the first one is touchable when working, it is very safe. The other is that it has a memory function.

Users can develop their own robot control system based on the API of OPTIMAS robot. Meanwhile, OPTIMAS robot is equipped with its own programmable interface, which allows the user to observe robot’s operating status in real time, carry out lots of robot control settings and perform offline simulation. This can improve the efficiency of practical application greatly.

OPTIMAS MR-5, the second generation of smart lightweight 6 DOF modular collaborative robot, whose payload is 5kg, is one of OPTIMAS series modular robots.

Advantages

1. Stability and improve quality, ensure its homogeneity;

2. Improve productivity, available 24 hours a day continuous production;

3. Improving labor conditions, long-term work in a hazardous environment;

4. Reduce the operation technique requirements;

5. Reduce product modification replacement cycles, reduce investment in appropriate equipment;

6. Realization of welding automation of batch products;

7. Save floor space;

8. Safe to work with humans.

Applications:

This robot small size light weight, is dedicated to arc welding robot, can realize the stable welding, obtain high precision welding path, shorten the welding cycle, extend the life of the pipe and cable at the same time SA series welding robot can flexible welding operations within the narrow space, can easily choose the ground installation mount inversion

Specification

We can customize the solution according to the information you provide, whether it is automatic cutting system, automatic welding system, automatic painting, automatic feeding, unloading, etc. We can design exclusive solutions for you. A strong technical team and bilingual communication skills can quickly solve any of your needs. German technology, made in China, high cost performance. Please feel free to contact us for more information.

1.Q:What is the warranty of the robotic arms?

A:Questt Lasers have a warranty for 1-2 years.

2.Q:Are you a factory or trading company?

A:Quesstt Lasers is a factory for 22 years. Got import and export License.

3.Q:How about the quality?

A:Quesstt Lasers Technology is from Germany.High quality best price.

4.Q:What is your after-sale service?

A:If needed,Questt Lasers offer door to door service !we can send engineers to your factory for assembling ,adjusting and training!

5.Q:How do i get technical support after purchasing?

A:Questt Lasers offer online service in English through Skype,WhatsAPP,Wechat or Email etc .If need remote operation,we can use TeamViewer software.

6.Q:How can i get assurance of my Payment?

A:Alibaba have Trade Assurance,you can pay throught Alibaba first.