Керамическая изоляционная подложка Al2O3 и

- Категория: Electronic Accessories & Supplies >>>

- Поставщик: Xiamen,Unipretec,Ceramic,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.3 $* | 0.40 $* |

| Aug-18-2025 | 0.7 $* | 0.64 $* |

| Jul-18-2025 | 0.82 $* | 0.18 $* |

| Jun-18-2025 | 0.45 $* | 0.65 $* |

| May-18-2025 | 0.58 $* | 0.33 $* |

| Apr-18-2025 | 0.32 $* | 0.6 $* |

| Mar-18-2025 | 0.97 $* | 0.44 $* |

| Feb-18-2025 | 0.87 $* | 0.80 $* |

| Jan-18-2025 | 0.12 $* | 0.65 $* |

Характеристики

Product Features

√ fast delivery | √ low thermal expansion | √ high thermal conductivity |

√ high working temperature | √ good metalization capacity | √ excellent electrical insulation |

√ CTE close to that of Silicon (Si) | √ corrosion and erosion resistant | ... |

Description

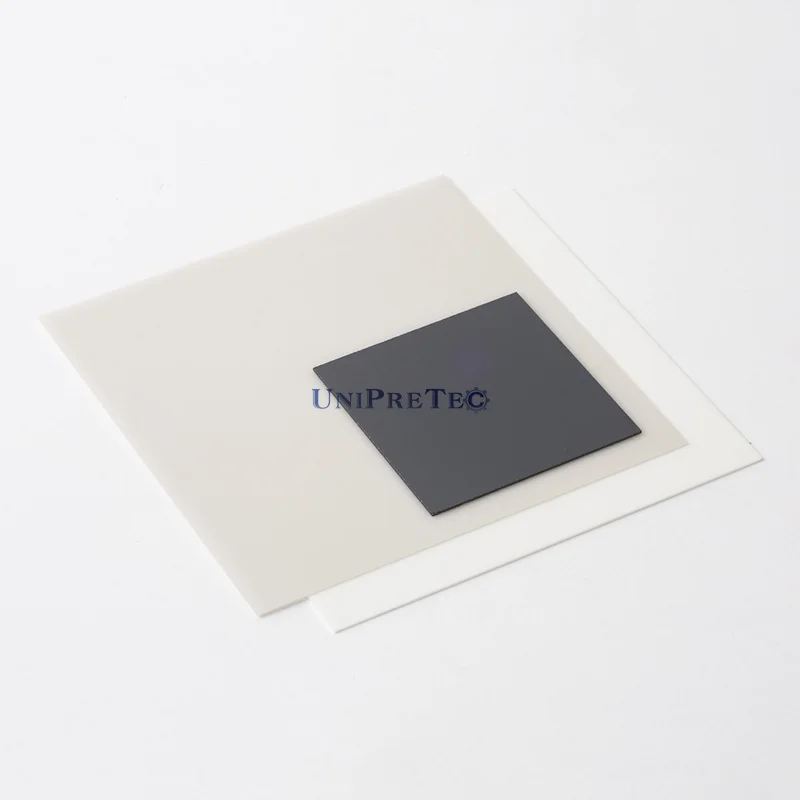

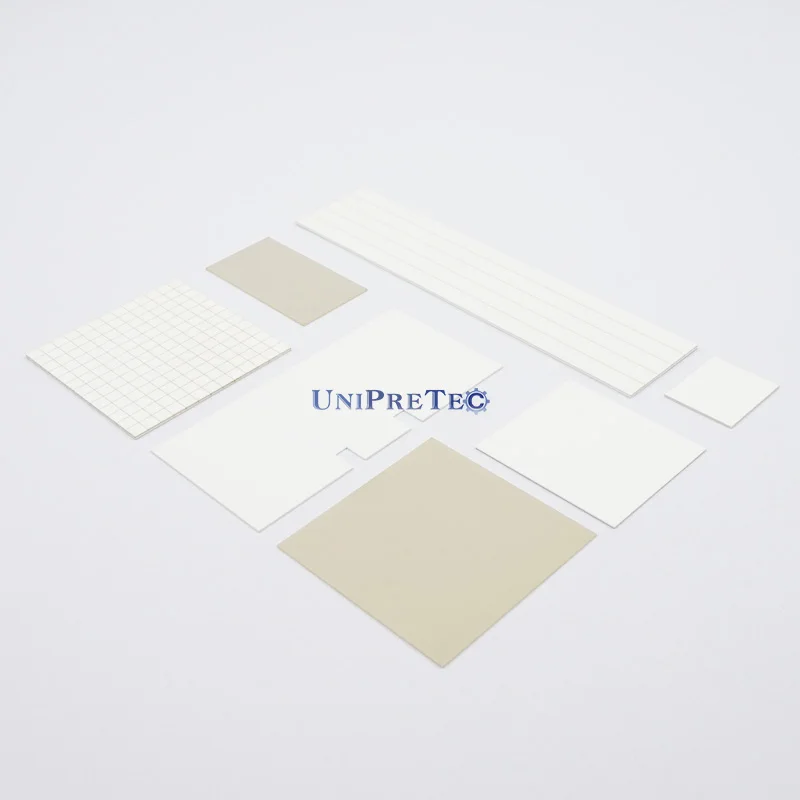

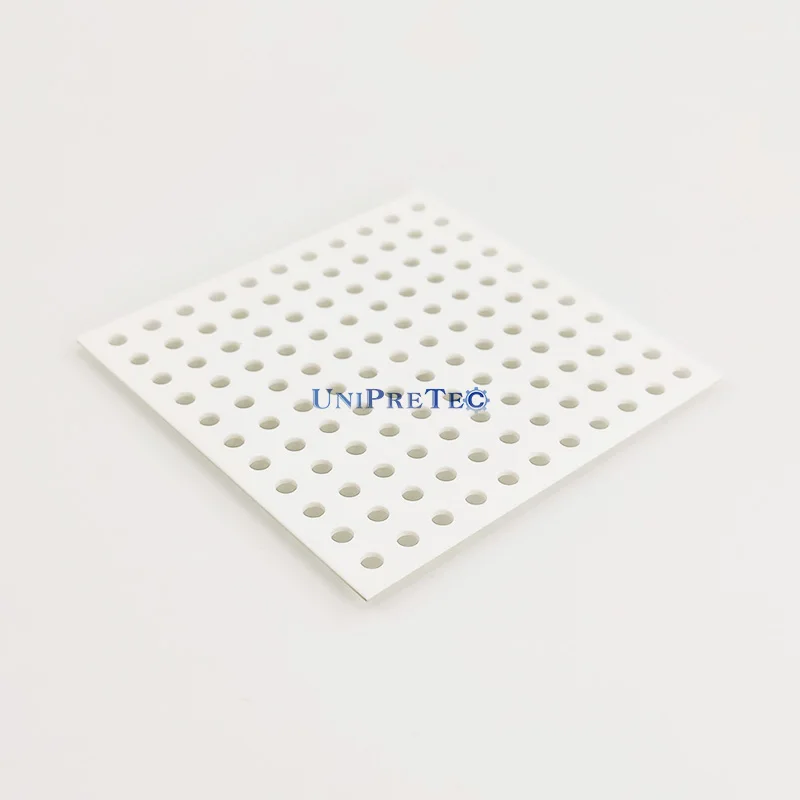

Al2O3 Alumina Ceramic Substrates:

This ceramic material is characterized by its extremely high strength and thermal conductivity. The outstanding surface quality on both sides makes it the perfect companion for any commercial thick film paste and even makes it suitable for a number of thin film applications (sputtering). A960 Alumina offers consistently reliable and convincing performance even when subject to high thermal and electrical loads in terms of its: Thermocycling capability, Thermal shock resistance, Flexural strength, Surface quality, Thermal conductivity. This makes A960 Alumina Ceramic Substrates ideal for power electronics in conjunction with direct copper bonding (DCB) and active metal brazing (AMB).

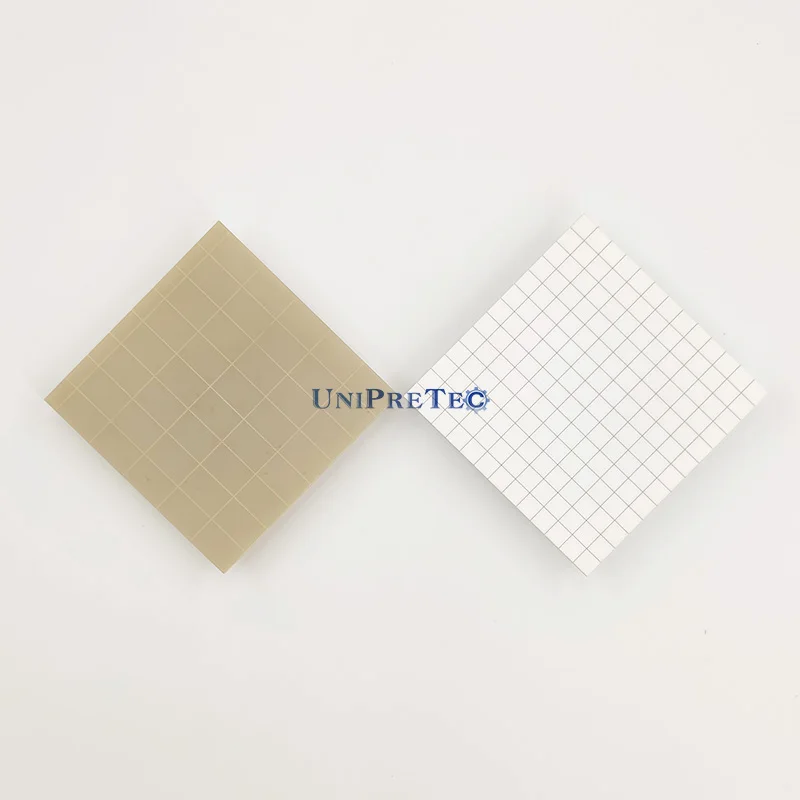

AlN Aluminum Nitride Ceramic Substrates:

Achieving maximum performance in the smallest possible space inevitably causes electronic components to develop increasingly high temperatures. This heat must be dissipated quickly and reliably in order to protect the valuable components. This is where UNIPRETEC's AlN(Aluminum Nitride Ceramics) sets the benchmark. With outstanding insulating properties and extremely high thermal conductivity (≥ 170 W/mK), Aluminum Nitride is perfect for the extremely high performance required in the electronics industry. AlN ceramic enables the compact, affordable construction of components and hybrid designs with high integration density. Extraordinary mechanical strength and a low thermal expansion coefficient enable seamless system integration.

Material Properties

ITEM | UNIT | AlN | A960 |

Main Content | - | AlN > 95% | Al2O3 > 96% |

Color | - | Grey | White |

Density | g/cm3 | > 3.3 | > 3.7 |

Water Absorption | % | 0 | 0 |

Surface Roughness (Ra) | um | 0.3 - 0.6 | 0.2 - 0.7 |

Warpage | - | < 2‰ | < 2‰ |

Flexural Strength | Mpa | 440 | 380 |

Thermal Conductivity (25 ℃) | W/m.K | > 175 | > 25 |

Thermal Expansion Coefficient (25 - 300 ℃) | 10-6 mm/℃ | 2 - 3 | 6.5 - 7.5 |

Thermal Expansion Coefficient (300 - 800 ℃) | 10-6 mm/℃ | 2.5 - 3.5 | 6.5 - 8.0 |

Working Temp. | ℃ | < 1200 | < 1200 |

Dielectric Strength | KV/㎜ | > 17 | > 17 |

Dielectric Constant | 1 MHz | 17 | 9 - 10 |

Electrical Resistivity (25 ℃) | Ω·cm | > 1014 | > 1014 |

∆ The above data is offered for reference and comparison only, exact data will vary depending on manufacturing method and part configuration.

Applications

About Us

UNIPRETEC is a representative technical ceramic company in China. Relying on the technical team with more than 10 years of experience and the cooperation of well-known domestic colleges and institutions, our company covers the manufacturing and sales of oxide, nitride and carbide ceramic products. Based on the research in the advanced ceramic industry, our company is good at providing suitable products and suggestions flexibly according to customers' applications and needs. For many years, our company has focused on meeting the needs of customers from all over the world. Many praises from customers and partners have been encouraging UNIPRETEC to move forward and develop.

"Simple things into very complex, can find new areas; Read the complex phenomenon is very simple, can be found that the new law." - - - - - -Isaac Newton