Папка для сушки горячим воздухом специально силикатной доски

- Категория: Hot Air Furnace >>>

- Поставщик: Anhui,Jixingyuan,Technology,Joint-Stock,Co.,Ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.5 $* | 0.74 $* |

| Aug-18-2025 | 0.78 $* | 0.55 $* |

| Jul-18-2025 | 0.73 $* | 0.55 $* |

| Jun-18-2025 | 0.58 $* | 0.46 $* |

| May-18-2025 | 0.24 $* | 0.16 $* |

| Apr-18-2025 | 0.30 $* | 0.11 $* |

| Mar-18-2025 | 0.91 $* | 0.31 $* |

| Feb-18-2025 | 0.9 $* | 0.98 $* |

| Jan-18-2025 | 0.5 $* | 0.78 $* |

Характеристики

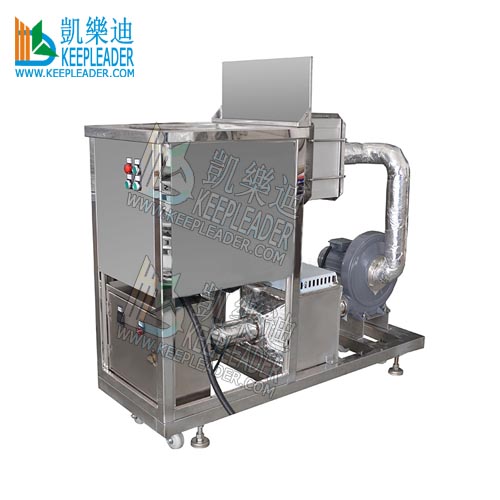

Folder Hot Air Drying Tunnel Special For Calcium Silicate Board | |

Effective Working Thickness | 2 ~ 80 mm |

Effective Working Width | 300 ~ 1300 mm |

Conveying Speed | 5 ~ 15 m/min |

Max Working Weight | 80 kg (single board) |

Feeding Speed | 6 pcs/min |

Main Feature:

The whole machine adopts high thermal insulation material, which is more energy-saving and better in thermal insulation effect. The plate is erected and moved in three dimensions.

the machine is about 3 meters wide, each conveyor chain is equipped with two comb teeth, namely the support frame, each support frame height is greater than 80CM; the spacing between the front and rear support frames is about 10.1CM, to facilitate the horizontal placement of the plates After the upper part, an angle is formed, and the support frame is provided with an elastic rubber ring, so as to ensure that the paint film will not be damaged and scratched during long-distance transportation and lower plate, which lays a solid foundation for the coating quality of the product. .

the conveyor is 32-inch large chain conveyor, there are guide bars at both ends, there are pulleys in the middle of each chain tooth, the bearing capacity is larger and no friction, the operation is more stable; driven by high-power geared motor and converted by imported frequency converter The control realizes the frequency conversion speed regulation and is suitable for the requirements of different line speeds. The connecting rods at both ends are large round rods, and each of the large round rods is provided with two supporting frames, and a special material connecting belt between the front and rear large round rods effectively prevents the sheet from slipping and contacting the chain.

A 600mm wide air duct is reserved inside the entire thermal insulation wall. People can enter and carry out equipment maintenance, and separate them into 14 return air chambers. There are air inlets and return air outlets, which form convection with the inlet hot air, corresponding to the wind chamber. The whole machine is equipped with 14 sets of large-area circular space aluminum finned radiators. The heat of the radiator is blown into the drying tunnel by the heat exchange fan. The hot air passes through the sheet to accelerate the evaporation of the thinner material of the paint and shorten the drying time of the paint. The exhaust gas such as thinner is pumped out to the air by the exhaust fan, and the other part is pumped back into the radiator chassis for heating cycle to ensure that the internal heat energy of the machine is not lost, achieving energy saving.

The size of the steam flow is controlled by the temperature sensor and the automatic valve. When the temperature exceeds the set temperature, the automatic valve control switch reduces the steam flow to reach a constant temperature inside the box. When the temperature is lower than the set temperature, the automatic valve control switch Increase the steam flow to raise the surface temperature of the radiator to heat the inside of the tank.

According to different drying characteristics of different coatings, the heating system can be divided into four sections, namely preheating stage, heating stage, forced drying stage and cooling stage; taking 50M folding drying kiln as an example: the first 7 meters is preheating stage. The running time of the board in the chassis is about 11 minutes, and the temperature is controlled to room temperature ~40Co, which makes the thin material in the paint on the board slowly volatilize, effectively preventing the generation of bubbles and needles; the middle section is heating and forced drying stage, heating The section is 5 meters, the forced drying section is 30 meters, the running time of the board in the cabinet is about 56 minutes, the temperature is controlled to 50~100Co, and the glue chemical reaction of the paint resin and the curing agent is accelerated to achieve the effect of rapid drying and solidification. The rear section is the cooling air cooling process of the water air conditioner, which reduces the temperature of the paint surface to form a relatively strong paint film. The cooling section is 8 meters, and the running time of the board in the chassis is about 13 minutes, preventing the large particles of dust in the outside air from affecting the paint surface. The effect is to control the plate temperature of the paint panel to about 5~8Co above room temperature to prevent mucosal phenomena from being too high.

This machine is equipped with single-action and linkage control devices and is controlled by PLC to control its operation and functions. Any guidance or damage to the parts is displayed by text, which is very convenient for on-site maintenance and protection.

The feeding uphill machine is used in front of the folding page, and the automatic feeding process is used to control the plate conveying and has an automatic waiting function, so that the plate is ordered into the U-shaped card position device, and the U-shaped comb teeth of the folding drying tunnel support the plate. The back side rises into the inside of the folding drying tunnel to carry out the heating leveling drying process, which effectively avoids the external force damage and pollution of the coated board. The uniquely designed multi-column work conveying platform perfectly cooperates with the mechanical structure of the folding drying tunnel. The three special customized imported seamless circular conveyor belts have high wear resistance coefficient, which can effectively limit the effective position of the plates and ensure accurate feeding. Durable, smooth and powerful feeding

Multi-row type flattening leveling machine is used for folding behind the page, and the plate is conveyed by the program and has an automatic waiting function, so that the plate is conveyed and leveled out from the U-shaped card position device at the discharge end of the folding drying tunnel, and the flat conveying is carried out. The U-shaped support frame of the folding drying tunnel is used as a support point, so that the painted surface of the plate faces upward and is synchronously descended and conveyed with the U-shaped support frame, and at the same time, after receiving the instruction of the control program, the machine raises a bracket through the cylinder. When the support plate is turned over, it will slowly slide down and level off to ensure that the painted surface of the plate surface is not contaminated and damaged. The specially designed multi-row work conveying flat platform is perfectly matched with the folding drying tunnel. The three special customized imported seamless endless conveyor belts have high wear resistance coefficient, which can effectively flatten and discharge the sheet, durable and stable feeding. powerful.

Control unit: Control and detection system consisting of Siemens PLC, Weilun man-machine interface, Siemens inverter, Siemens brand servo drive; during manual control, equipment start/stop and speed adjustment are controlled by inverter panel; The device is electrically locked; when it is automatically controlled, it can be transported through the man-machine interface speed control device, etc., the operation panel automatically starts the device with one button; the three-layer three-color tower lamp is used to indicate the running status of the device and the fault alarm indication

Application In Production Line (Customer Factory)

Application In Paint

Application In Products

- Anhui Jixing Yuan is a professional enterprise and manufacturer of coating equipment. PAMA Technology is part of Jixing Yuan. In order to cater to overseas high quality market, we launched the PAMA high-end series brand in 2018. Provide high quality products and professional technical support to overseas customers.

- The factory is located in Huainan, a beautiful inland city. Close to Shanghai and Hangzhou.

=== WHY CHOOSE US ===

|

|

|

|

Our products are exported to many countries and regions overseas. Providing quality services and products to customers around the world.

- A variety of payment methods, including T / T, Western Union, letter of credit, PayPal, etc.

- 1 year oversea technical service is avilable.

- 1 year warranty for the machines.

- 10 year accesories supply guarantee.

- Lifetime technical guidance.

- Call or email anytime if you have any question for our machines.

- Packing in standard export wooden cases.

- The bulk goods are transported by sea, train or others. Accessories can be sent by international express.