Низкая цена Высокоэффективная машина для производства древесного угля и сотовых

- Категория: Briquette Machines >>>

- Поставщик: Gongyi,Xiaoyi,Mingyang,Machinery,Plant

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.61 $* | 0.28 $* |

| Aug-18-2025 | 0.95 $* | 0.3 $* |

| Jul-18-2025 | 0.7 $* | 0.20 $* |

| Jun-18-2025 | 0.43 $* | 0.75 $* |

| May-18-2025 | 0.39 $* | 0.70 $* |

| Apr-18-2025 | 0.51 $* | 0.27 $* |

| Mar-18-2025 | 0.35 $* | 0.31 $* |

| Feb-18-2025 | 0.28 $* | 0.72 $* |

| Jan-18-2025 | 0.44 $* | 0.91 $* |

Характеристики

The production line:

1.Crush the raw material into small pieces (diameter is about 3-5mm);

2.Dry the material by dryer machine , till the moisture is less than 12%;

3.Put the material into rotary carbonization stove;

4.Then put the charcoal dust into the honeycomb charcoal press machine.

Product Application

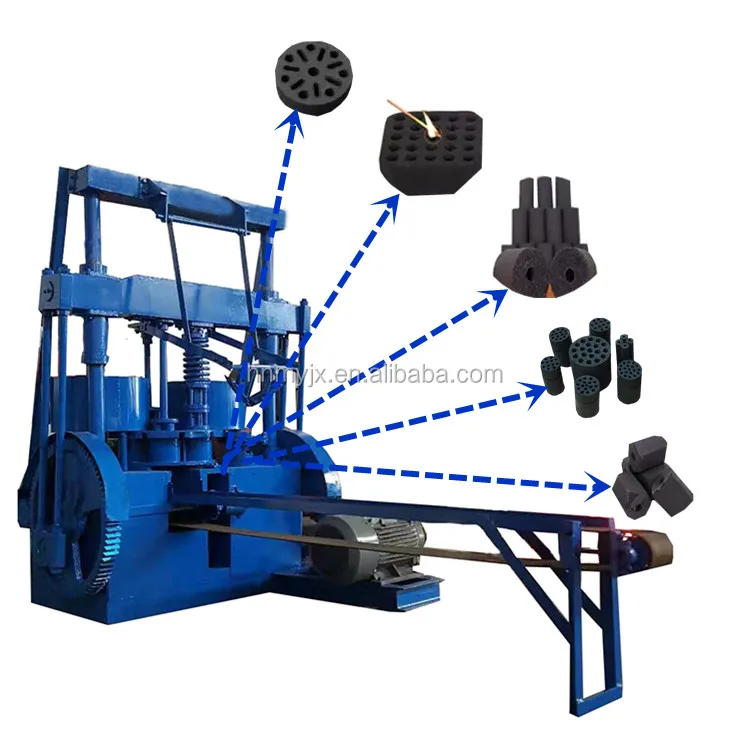

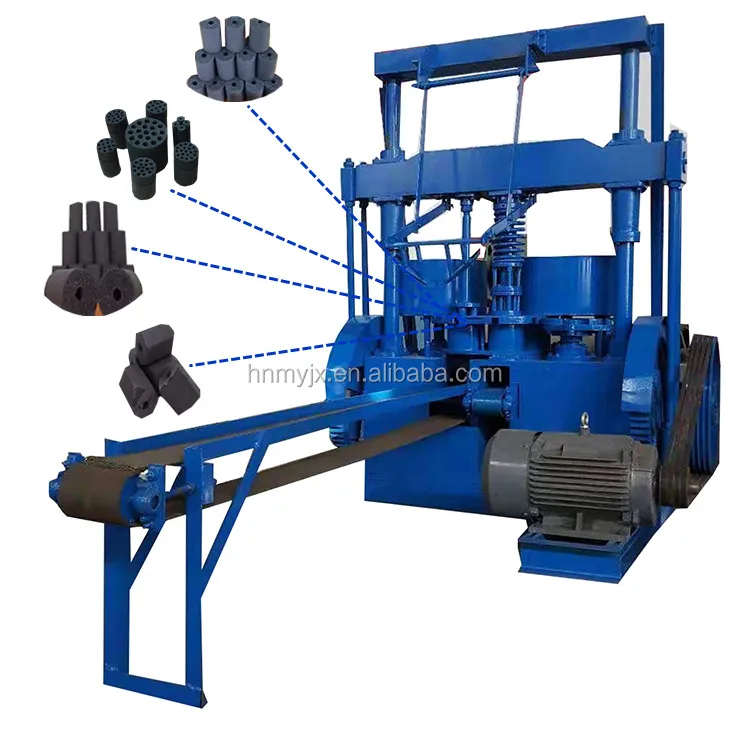

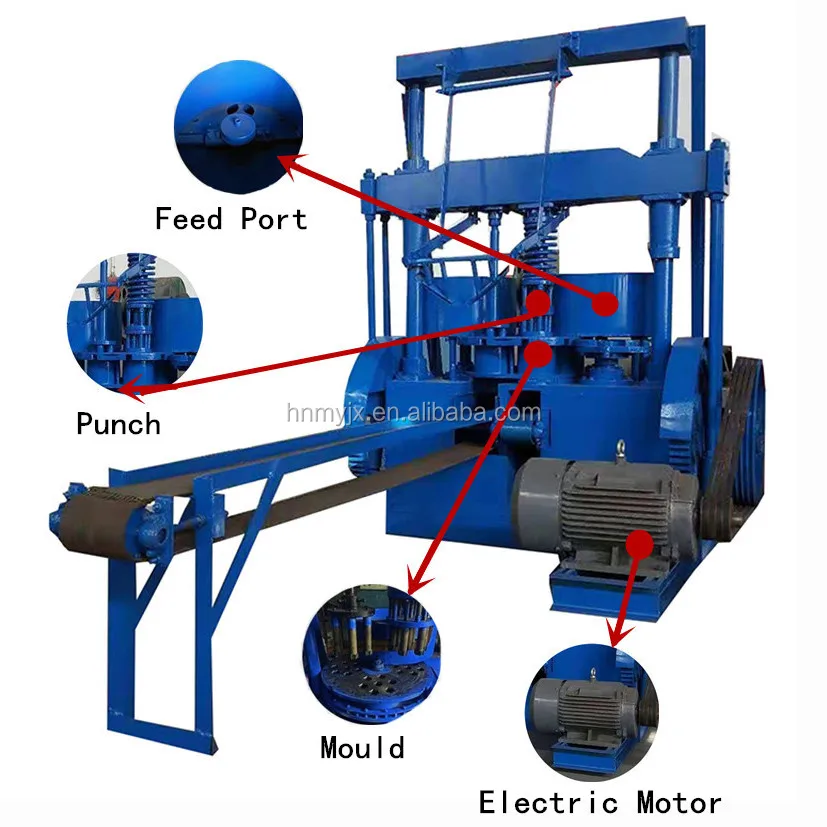

The honeycomb press machine is mainly used to make the coal briquettes in honeycomb shapes. It has been popularly used in China for almost 80 years. Previously raw coal been processed into the coal sphere slightly larger than ping-pong, and later the coal processed into one cylinder, and marked with a number of holes inside the cylinder makes it seems like honeycomb, because it can increase the surface area of coal, make the full combustion of coal, to reduce resource waste. Mostly it is used in coal, metallurgical powder, powder cold-pressing ball, refractory materials.

SPECIFICATIONS FOR HONEYCOMB BRIQUETTE MACHINE 140 | ||||||

honeycomb briquette machine 140 | power | 7.5kw | ||||

capacity | 50 piece/min | |||||

Weight | 1950kg | |||||

Advantages:

1. high profit and low cost in raw material

2. increase the net calorific value per unit volume after briquetting

3. energy saving, friendly-environment, low-consumption

4. no chemical addictives, no smell, no smoke

5. easy to transport and store as densities product

Model | Power( kw) | Capacity( piece/min) | Feeder height(mm) | Packing size(m) | Weight |

140 | 7.5KW | 45 | 930mm | 2.85*1.22*1.83 | 1500kg |

140 | 7.5KW | 50 | 930mm | 2.85*1.22*1.83 | 1950kg |

160 | 7.5KW | 50 | 970mm | 3.05*1.28*1.86 | 2150kg |

180 | 11KW | 22-26 | 1000mm | 3.2*1.28*1.86 | 2500kg |

220 | 11KW | 22-26 | 1050mm | 3.40*1.35*2.0 | 3500kg |

1. Raw material scop: any kinds of coal and charcoal powder

2. Raw material diameter: less than 3mm

3. Raw material moisture content: 8-15%

1. Shape: the outlet shapes of honeycomb briquette machine can be various honeycomb shape and columnar rod shapes and we can customize different shapes as your needs.

2. Size: the final size is according the machines, and each model of machine has itself minium and maxmium size.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Gongyi Xiaoyi Mingyang Machinery plant is located in Zhengzhou.Henan province. Our machineryplant is specialize in WOOD BRIQUETTE MACHINE 26 years.

There have production line of makingwood charcoal briquette(including crusher , dryer , wood briquette machine, carbonization stove) ,

production line of making wood pellet (including crusher, dryer , wood pellets machine , dust separation plant and packaging machine)

production line of making coal ball briquette(includingvertical crusher, mixing machine, coal briquette pressing machine and dryer machine for coal briquette)

and other equipment such as screw conveyor, belt conveyor, scrap conveyor , sawdust carbonization stove, floating fish feed machine and so on.

Our machines have the best quality and we have got many certification such as CE, ISO, BV.

ave got many certification such as CE, ISO, BV.

If you have interest on our machine or have questions on our machine, please don't hesitate to contact us.