Высокопроизводительный гранулятор PCB для переработки отходов с высокой прибылью на

- Категория: Other Recycling Products >>>

- Поставщик: Henan,Doing,Environmental,Protection,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 28560.3 $* | 29988.39 $* |

| Aug-18-2025 | 28320.43 $* | 29736.39 $* |

| Jul-18-2025 | 23760.96 $* | 24948.89 $* |

| Jun-18-2025 | 27840.39 $* | 29232.86 $* |

| May-18-2025 | 24240.71 $* | 25452.83 $* |

| Apr-18-2025 | 27360.59 $* | 28728.27 $* |

| Mar-18-2025 | 27120.14 $* | 28476.44 $* |

| Feb-18-2025 | 26880.31 $* | 28224.54 $* |

| Jan-18-2025 | 26640.19 $* | 27972.4 $* |

Характеристики

| High capacity and high profit waste PCB granulator recycling plant for sale |

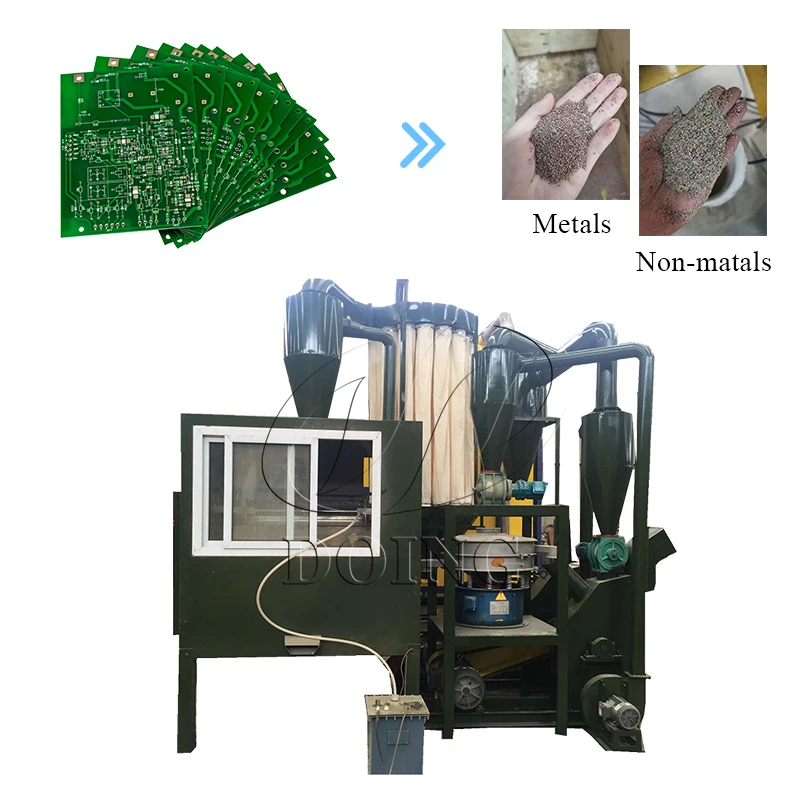

Waste PCB granulator recycling plant is a kind of waste processing machinery, specially for processing the e waste circuit boards to separated metals and nonmetal materials for recycle use, like scrap printed circuit boards, CCL (copper-clad plate), the leftover materials from the PCB production factory, computer boards, TV boards, and the waste motherboards generated from all kinds of electric appliance.

Our waste PCB granulator recycling plant adopts dry type and physical crushing, separation and dedusting methods, which can keep no pollution to the environment. And the high pressure electrostatic separation combined with air separation process make the metal recovery rate up to 99% or higher.

| Working process of waste PCB granulator recycling plant |

| Technical Parameter of waste PCB granulator recycling plant |

| Model | Capacity | Power | Overall Dimension | Weight | Recovery Rate |

| DY-400 | 100-200kg/h | 45kw | 4000*3500*4200mm | 4250kg | >=99% |

| DY-500 | 200-300kg/h | 68kw | 7000*4000*4500mm | 6500kg | |

| DY-600 | 300-500kg/h | 110kw | 7500*4500*4800mm | 8500kg | |

| DY-800 | 500-800kg/h | 155kw | 8500*5500*5000mm | 10500kg | |

| DY-1000 | 800-1000kg/h | 198kw | 10000*6000*5250mm | 12500kg |

| Main Features of waste PCB granulator recycling plant |

1. The whole waste PCB granulator recycling plant process is controlled by PLC system, easy to operate, fully automatic;

2. Reasonable layout with compact structure, stable performance, low noise;

3. The crushing process include primary shredding and fine crushing with circulation water cooling to ensure the good performance;

4. Adopt negative pressure feeding system with pulse dust collector, which ensure no dust leakage and clean working environment;

5. The separation process adopts air separation and electrostatic separation methods, the separation rate of metals and nonmetals could reach to higher than 99%.

| Package & Shipments of waste PCB granulator recycling plant |

| Auxiliary Equipment for waste PCB granulator recycling plant |

PCB dismantling machine is the supporting equipment for waste PCB granulator recycling plant to dismantle the electronic components from PCB base boards before crushing and separation process. The electronic components dismantled from PCB base boards could be collected and sold separately.

| Customer Visiting |

| Our Company |

Henan Doing Mechanical Equipment Co.Ltd is a comprehensive enterprise related to research, manufacture, marketing, technical support and installation service. We have been concentrating on developing and manufacturing many kinds of waste recycling machinery, include cable wire recycling machine, Printed circuit board (PCB) recycling machine, Aluminum plastic composite recycling machine, medical blister pack recycling machine, radiator recycling machine, waste tire and plastic recycling machine, etc. All the equipments adopt green technology which have no pollution to the environment.

| Company Certification |

| Our Service |

♦ Pre-sale Service

(1) According to the customers' special requirements, provide the most suitable project design, process design and the purchase program.

(2) Guide customers to choose the best and economical plant, recover investment within short time, and site inspection.

♦ On sale service

(1) Welcome you to our factory for a visiting;

(2) Accompany you to check our machine production, quality and the working conditions.

(3) Customize the equipments strictly according to your special requirements and arrange the timely delivery.

♦ After-sale service

(1) Installation guidance

When the machine arrives at your company, we will dispatch our technicians to your factory to guide the installation and commissioning at site.

(2) Technical training

We provide free technical training service to your stuff. Training content contains the main work principle of machine, operating regulations, maintenance methods and steps, safety, etc.

(3) Warranty

Three guarantees of our product quality, warranty for one year (not include man-made damaged). We will maintain the machine for free for the quality problem. If the damage is caused by your improperly operation, the cost of the maintenance burden by you. we also provide you the life-long follow-up service.