Машина Для Обезвоживания Сточных Вод без

- Категория: Очистное оборудование >>>

- Поставщик: Jiangsu,Benenv,Environmental,Technology,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 1190.2 $* | 1250.3 $* |

| Aug-17-2025 | 1180.15 $* | 1239.14 $* |

| Jul-17-2025 | 990.79 $* | 1040.79 $* |

| Jun-17-2025 | 1160.88 $* | 1218.97 $* |

| May-17-2025 | 1010.68 $* | 1061.60 $* |

| Apr-17-2025 | 1140.38 $* | 1197.49 $* |

| Mar-17-2025 | 1130.23 $* | 1187.74 $* |

| Feb-17-2025 | 1120.34 $* | 1176.72 $* |

| Jan-17-2025 | 1110.57 $* | 1166.77 $* |

Характеристики

Specifications of Clog free sludge dewatering press machine for slaughtering sewage dewatering | ||||||

Main Parameters | Capacity | DS-kg/hr | 1-600 DS-kg/hr | |||

Size | mm | L4564*W2100*H2156 | ||||

Power | kW | 6.0 | ||||

Motor | Gearbox | Brand | SEW, BAUER, SUMITOMO, NISSEI | |||

Protection | Certificates & IP | UL,CE, Water proof(IP65) CCC | ||||

Screw Shaft | Treatment | SUS316L, Tungsten carbide coating | ||||

Control Cabinet | Electrical Components | Brand | Schneider, Omron, Siemens | |||

Solenoid Valve | Brand | US,ASCO | ||||

Spray System | Brand | Japan Origin, H.IKEUCHI | ||||

Model | Raw Wastewater Waste Activated Sludge(WAS) & Chemically Precipitated Sludge (Thin Sludge) | Dissolved Air Flotation Sludge | Mixed Raw Sludge Aerobic Digested Sludge & Sewage Sludge | ||||

Sludge Concentration (TS) | 0.2% | 1% | 2% | 5% | 3% | ||

MDS 051 | ~0.4 kg-DS/hr (0.2 m³/hr) | ~0.6 kg-DS/hr (0.06 m³/hr) | ~2 kg-DS/hr (0.1 m³/hr) | ~4 kg-DS/hr (0.08 m³/hr) | ~5 kg-DS/hr (0.16 m³/hr) | ||

MDS 101 | ~2 kg-DS/hr (1.0 m³/hr) | ~3 kg-DS/hr (0.3 m³/hr) | ~5 kg-DS/hr (0.25 m³/hr) | ~10 kg-DS/hr (0.2 m³/hr) | ~13 kg-DS/hr (0.43 m³/hr) | ||

MDS 131 | ~4 kg-DS/hr (2.0 m³/hr) | ~6 kg-DS/hr (0.6 m³/hr) | ~10 kg-DS/hr (0.5 m³/hr) | ~20 kg-DS/hr (0.4 m³/hr) | ~26 kg-DS/hr (0.87 m³/hr) | ||

MDS 132 | ~8 kg-DS/hr (4.0 m³/hr) | ~12 kg-DS/hr (1.2 m³/hr) | ~20 kg-DS/hr (1.0 m³/hr) | ~40 kg-DS/hr (0.8 m³/hr) | ~52 kg-DS/hr (1.73 m³/hr) | ||

MDS 202 | ~16 kg-DS/hr (8.0 m³/hr) | ~24 kg-DS/hr (2.4 m³/hr) | ~40 kg-DS/hr (2.0 m³/hr) | ~80 kg-DS/hr (1.6 m³/hr) | ~104 kg-DS/hr (3.47 m³/hr) | ||

MDS 311 | ~20 kg-DS/hr (10 m³/hr) | ~30 kg-DS/hr (3.0 m³/hr) | ~50 kg-DS/hr (2.5 m³/hr) | ~100 kg-DS/hr (2.0 m³/hr) | ~130 kg-DS/hr (4.33 m³/hr) | ||

MDS 312 | ~40 kg-DS/hr (20 m³/hr) | ~60 kg-DS/hr (6.0 m³/hr) | ~100 kg-DS/hr (5.0 m³/hr) | ~200 kg-DS/hr (4.0 m³/hr) | ~260 kg-DS/hr (8.67 m³/hr) | ||

MDS 313 | ~60 kg-DS/hr (30 m³/hr) | ~90 kg-DS/hr (9.0 m³/hr) | ~150 kg-DS/hr (7.5 m³/hr) | ~300 kg-DS/hr (6.0 m³/hr) | ~390 kg-DS/hr (13 m³/hr) | ||

MDS 412 | ~80 kg-DS/hr (40 m³/hr) | ~120 kg-DS/hr (12 m³/hr) | ~200 kg-DS/hr (10 m³/hr) | ~400 kg-DS/hr (8.0 m³/hr) | ~520 kg-DS/hr (17.3 m³/hr) | ||

MDS 413 | ~120 kg-DS/hr (60 m³/hr) | ~180 kg-DS/hr (18 m³/hr) | ~300 kg-DS/hr (15 m³/hr) | ~600 kg-DS/hr (12 m³/hr) | ~780 kg-DS/hr (26 m³/hr) | ||

self-cleaning process. As a result, the ubiquitous clogging is avoided. The self-cleaning mechanism and stainless steel structure enables the screw press sludge dehydrator to handle oily sludge without any trouble, thus there is no need to add large quantity of flushing water.

Q: What’s MDS Sludge Dewatering Machine?

A: MDS Japanese quality 24hrs automatic oil sludge treatment equipment has been used in Japan market for over 30 years, is a mature technology. It was developed in our Japanese research center (Japan Benenv Co., Ltd.). We have Japanese engineers for technical support and quality control, other Chinese manufacturers they are just copy-cats from this Japanese technology, they are not original and lack of experience on this technology.

Q: What type of sludge is MDS Sludge Dewatering Machine applicable to?

A: It is applicable to various kinds of sludge such as waste activated sludge, dissolved-air floatation sludge and so forth. The thickening mechanism of this equipment enables dewater not only highly-concentrated sludge but also low-concentrated sludge with ease.

Q: What’s the application scope of MDS Sludge Dewatering Machine?

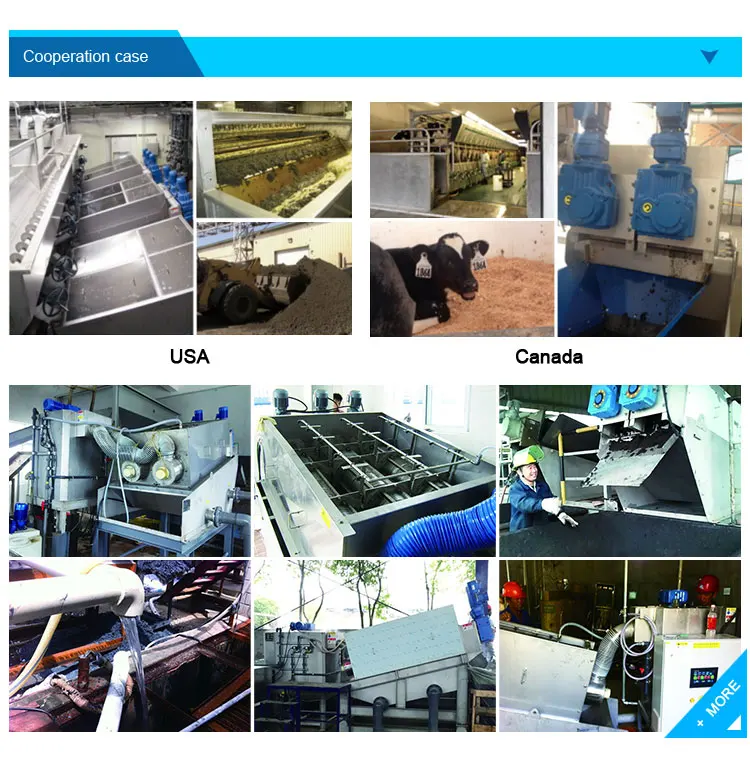

A: It is widely applied in Municipal water and wastewater treatment plants, Agricultural/fishery community wastewater treatment plants, Industrial waste treatment plants, Food/beverage production plants, Dairy farming/Meat processing plants, Chemicals manufacturing plants, Machinery manufacturing/Metal processing plants, Paper manufacturing, building material manufacturing, oilfield associated water accompanied with crude oil mining, etc..

Q: What’s the material of MDS Sludge Dewatering Machine?

A: It is Stainless Steel, we choose SUS304H, SUS316L, etc, some key parts we import from Japan, we also have our own workshop in Japan for production.

Q: What’s the equipment used together with MDS Sludge Dewatering Machine?

A: Sludge pump, polymer dosing pump, washing pump, air compressor.

Q: Why aren’t your rings carbonized like other companies’?

A: Carbonization is to harden and strengthen the metal surface. Our rings material is called 304 hardened steel (SUS304H), which is directly treated by our steel supplier, this hardened stainless steel can make the hardness of carbonized steel up to HV380-420 in China. Most of other manufacturers can reach to only HV250. This hardened steel SUS304H is 3 times expensive than normal SUS304, so other manufacturers they prefer to choose the normal material and need to increase the thickness of rings in order to increase the hardness, actually, increase the thickness of rings will affect the dewatering effects.

Q: How to choose the right model?

A: Advise us the sludge source, treating capacity, solid content rate, then we could choose the suitable model for you. Please put forward if you have special requirements.