Криогенный резервуар компании YDZ-230 с жидким азотом Цилиндр Бак сосуда под давлением для криосауна криотерапия

- Категория: Pressure Vessels >>>

- Поставщик: WOBO,Industrial,Group,Corp.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 1666.71 $* | 1749.20 $* |

| Aug-19-2025 | 1652.7 $* | 1735.33 $* |

| Jul-19-2025 | 1386.57 $* | 1455.63 $* |

| Jun-19-2025 | 1624.79 $* | 1705.44 $* |

| May-19-2025 | 1414.49 $* | 1485.83 $* |

| Apr-19-2025 | 1596.9 $* | 1676.38 $* |

| Mar-19-2025 | 1582.79 $* | 1661.64 $* |

| Feb-19-2025 | 1568.50 $* | 1646.27 $* |

| Jan-19-2025 | 1554.42 $* | 1632.79 $* |

Характеристики

Cryogenic Tank Companies YDZ-230 Liquid Nitrogen Container Cylinder Tank Pressure Vessel For Cryosauna Cryotherapy Chamber

Liquid nitrogen filling tank series use small amount of liquid nitrogen vaporizing to increase the pressure inside the tank, so that the tank can auto matically discharge liquid nitrogen to other containers. Mainly used for transport and storage of liquid nitrogen, and also as a cold source of other refrigeration devices. It can be equipped with monitoring device and monitoring software to alarm low liquid nitrogen level, high pressure and remote operation on pressure increase and discharge liquid nitrogen. It is widely used in the mold industry,animal husbandry, medicine, semiconductor, food, low temperature chemical,aerospace, military and other industries and fields.

Overview:

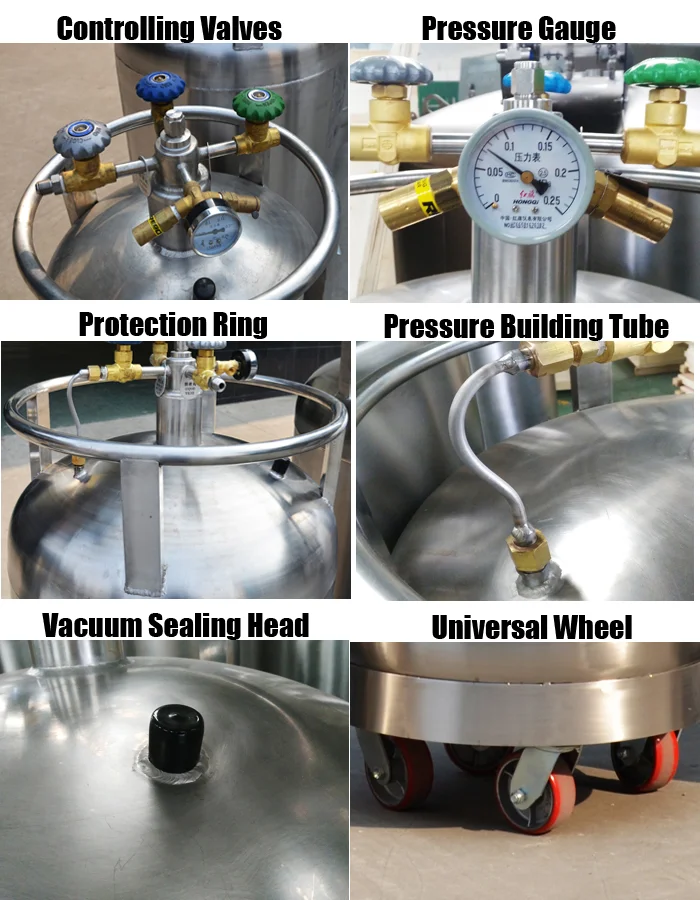

Liquid nitrogen filling tank series is mainly used for liquid nitrogen storage. It uses small amount of liquid nitrogen vaporizing to increase the pressure inside the tank, so that the tank can automatically discharge liquid nitrogen to other containers. The stainless steel structure design is suitable for most environment and reduces the rate of evaporation losses. All the models are equipped with pressure building valve, liquid valve, release valve and pressure gauge; and models over200 liters also equipped with bursting disc and muffler. All the models are equipped with 4 rollers at the bottom for easy to move. Mainly applicable to laboratory users and chemical users for liquid nitrogen storage and liquid nitrogen automatic supply.

1:Product Details

2:Application

Mold industry, animal husbandry, semiconductor, food, aerospace, low temperature chemical industry.

3:Self-pressured thery

When the inner tank is charged with liquid nitrogen, emptying valve, liquid draining valve,pressure valve closed, liquid nitrogen injection port plug and tighten.

After confirming the container without leakage, due to the heat transfer from the shell of the container to the pressure pipe, a part of liquid nitrogen entering the pipe for endothermic gasification. When the pressure valve is opened, the nitrogen after gasification enter via valve immediately into the interior surface upper space, at the same time, the liquid nitrogen from inner tank continuously enter into pressure tube for endothermic gasification.

Because of the volume of the nitrogen after gasification is more than 600 times of liquid nitrogen, a large amount of nitrogen gas transferred from a small amount of liquid nitrogen after gasification continuously enter into the inner tank through the opened booster valve. With the increasing amount of nitrogen gas, gathered in the inner level of the upper space gradually began to exert pressure on the inner wall and the surface, when the pressure displayed on pressure gauge reaches a value 0.02 MPa, open the drain valve, the liquid nitrogen will be discharged through a discharge pipe.

4:Manufacturing

The products control every aspect of production strictly in accordance with the high quality requirements with vacuum-pumping technology and multiple layers insulation technology.The adsorbent is processed by the regeneration to ensure the high quality vacuum layer;All the weld is checked by the helium mass spectrometer;The product is 100% tested by the liquid nitrogen;The unique polishing technology ensure the beautiful appearance.

5:Materials

1.High quality stainless steel 304

2.Oilless, fatless thin composite materials

6:Features

1.It is all made up of stainless steel and has high strength .

2.Unique tank bracket , good stability

3.High strength large castor, move conveniently

4.Five years vacuum warranty

5.Double safety valves structure ensure security

6.Unique neck design, low evaporation loss rate;

7.A protective operating ring

8.CE certified

7:Optional

1.Liquid level display

2.Digital signal remote transmission

3.Pressure regulator

4.Solenoid valve

5.Automatic filling system

Parameters:

Carton packaging. Mode of transport: by sea or by air or by train.

OEM, ODM. We can provide a good after-sales service.

We are focus on cryogenics for over 10 years, and can provide professional one-stop service for cryogenic vessels, equipment, and solutions.

We are good at non-standard customization service and developing new products on various cryogenic applications.

Cryo Chains is a high and new tech company, which is specialized in R&D, OEM and selling cryogenic container, cryogenic freezing equipment, and cryogenic solutions.

Cryo Chains has always been upholding the corporate concept that “the company should seek supreme quality, advanced technology, sincere service and innovative development”. We have a technical team of professional technical personnel with experience of about many years in R&D and manufacturing of various types of cryogenic liquid storage transportation, cryogenic freezing equipment.

We have accumulated rich experience in acquiring and keeping vacuum, multi-layer insulation, cryogenic freezing equipment and biological product cryopreservation, cryogenic intelligent electronic control system, and so forth. We have successful experience of several major cryogenic engineering implementations, we have established technical cooperation with various food plants, higher medical institutes and scientific research institutions.

Our business covers stem cell bank, blood bank, hospital, biological engineering, animal husbandry, higher institute, research institution, machinery, petrifaction, semi-conductor, aerospace, superconductor, industrial gas and liquid, metallurgy, frozen food preservation, and so on, and could provide mature project designs.

Our products have passed the test of national cryogenic liquid container testing center; meanwhile we get the CE certificate. The company strictly follows ISO 9001 quality control procedures to ensure its product quality and 100% qualified product rate. In the meanwhile, after-sale service system of quick response is established to make sure that users can safely use its products. Now our products have been sold to over 45 countries in the world and earn very good reputation.

Q: Is it widely used?

A: Suitable for mold industry, animal husbandry, medicine, semiconductor, food, aerospace, military, low temperature chemical industry.