Оптовая продажа цилиндр с высокой износостойкостью для экструдера двойным винтом/экструдера

- Категория: Plastic & Rubber Machinery Parts >>>

- Поставщик: Nanjing,Cowin,Extrusion,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 405.13 $* | 425.20 $* |

| Aug-17-2025 | 401.27 $* | 421.75 $* |

| Jul-17-2025 | 337.57 $* | 354.30 $* |

| Jun-17-2025 | 394.48 $* | 414.39 $* |

| May-17-2025 | 343.35 $* | 360.15 $* |

| Apr-17-2025 | 388.90 $* | 407.94 $* |

| Mar-17-2025 | 384.84 $* | 403.3 $* |

| Feb-17-2025 | 381.34 $* | 400.12 $* |

| Jan-17-2025 | 377.60 $* | 396.50 $* |

Характеристики

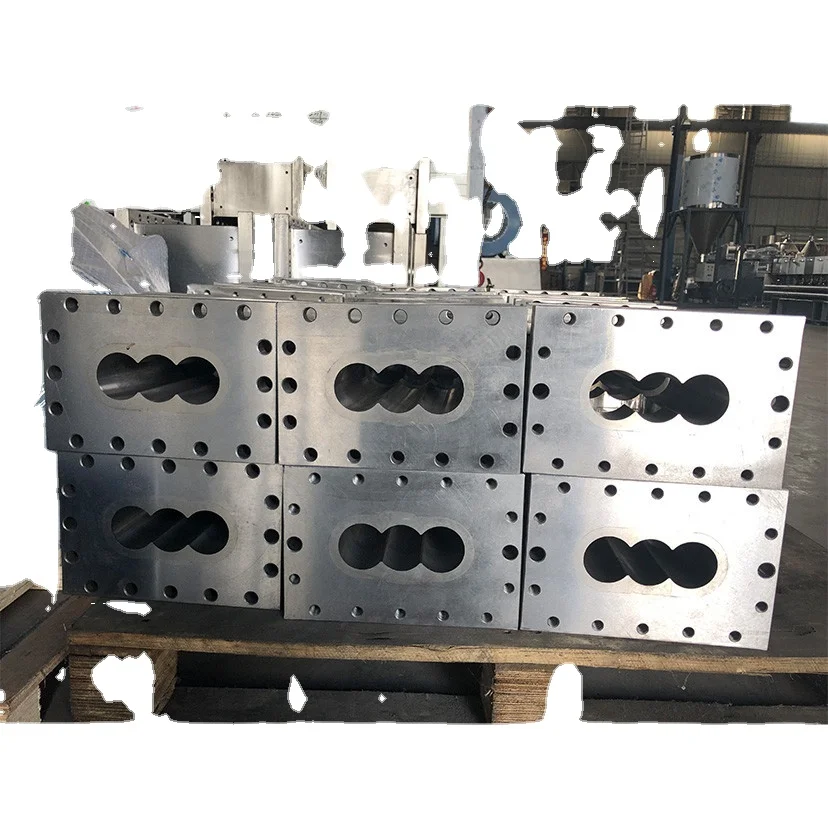

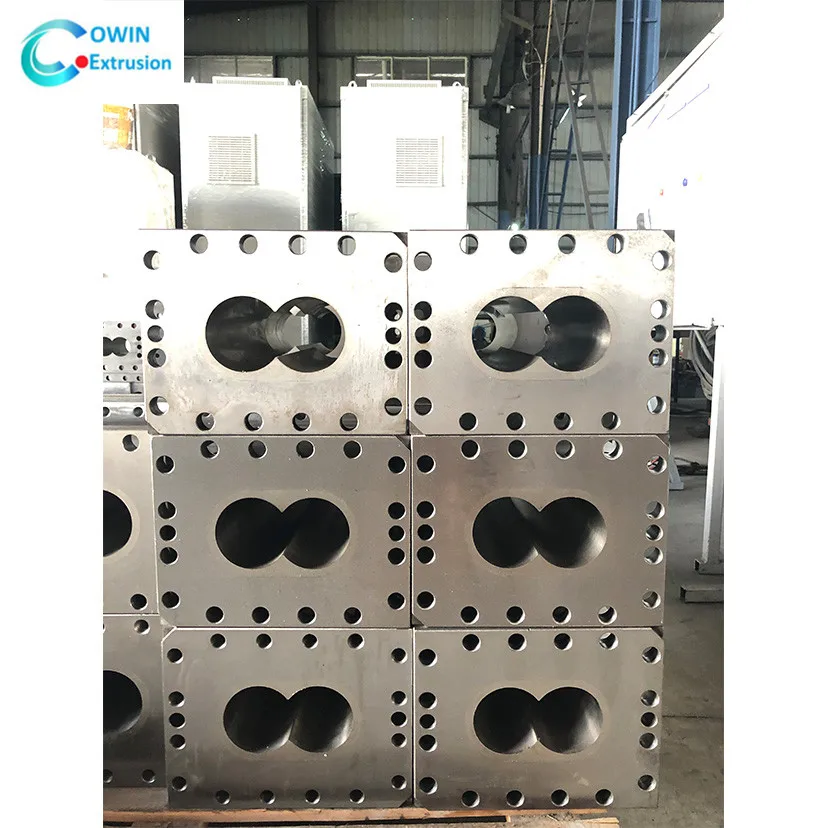

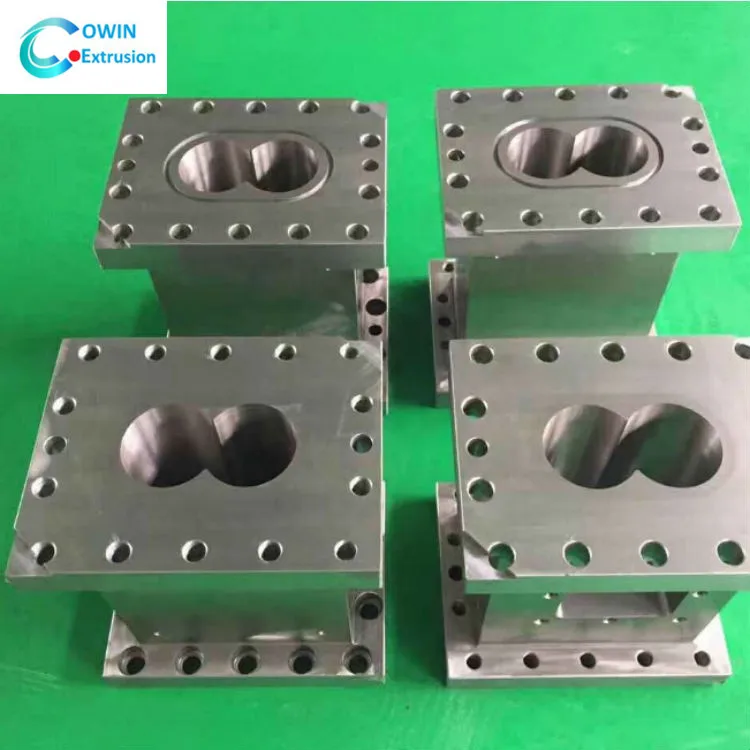

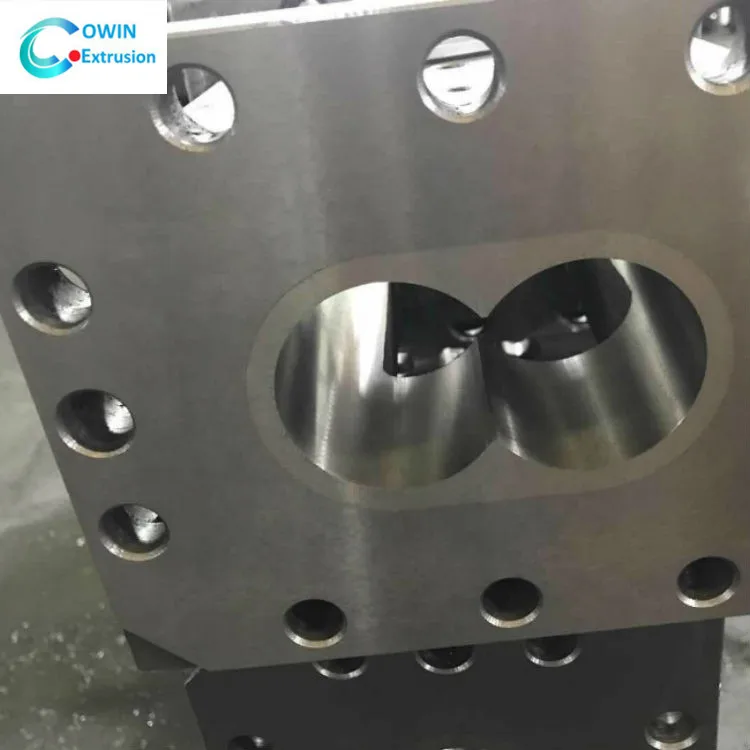

The flexible modular principle is realised with screw barrel sections from the wide range of different designs possible. The barrel sections are cooled with water, by means of an internal bore system, with bores arranged close to the inside barrel wall.

For bimeta barrels, generally we have three types of materials to provide:

(1) C-type liner

Bimetallic means the inside barrel hole made of alloy liner and outside base made of steel. Some typical elements for the liner can be:

| material type | chromium | carbon | other |

| α 101 | 20% | 2.5% | 8% V |

| α 301 | 18% | 2.5% | 6% Tungsten |

(2) Oval liner

It is made from one kind of high-chromium iron alloy (Cr12MoV), which is very famous in China these years due to its high wear resistant feature and its longer service life. We take our manufacturing process to a new level by introducing the oval liner products. We follow the unique formulation and ultimate techniques in our production that gives the best results in our supply.

(3) Imported material of world leading suppliers

For even higher wear resistance and higher corrosive resistance, we use imported material from Germany SAM26 - 26% chromium, 2.7% carbon and 3.5% V.

Modular barrels are available as follows for different processing requirements.

We adopt horizontal CNC, and advanced processing to machine the inner hole and pin hole at one time to ensure the coaxial degree of the barrel within 0.02mm. We use the advanced 3D measuring instrument to control the tolerances of each row of the cylinder.

Commissioning service includes supervision of installation and start-up, on-site training. Service charges are free.

· Free technical service and technical consultation should be adhered to before, during and after sales.

· Provide a complete set of technical information (including electrical schematic diagram, wiring diagram, outsourced parts instructions, product use instructions, etc.).

· Provide unit production process layout drawing, main screw assembly drawing, transmission box overhaul drawing;

· With the change of processing materials and processes and the development of new products, the corresponding screw assembly drawing and various technical consultation are provided free of charge.

· The equipment is guaranteed free of charge for one year. After the expiration of the warranty period, we still insist on after-sales service, spare parts only charge the cost price.

1. Q: Are you a factory or trading company,How is you factory extrusion experience?

A: We are a factory. 20 years experience on extrusion.Leading supplier in Nanjing city.

2.Q: How long is your machine's guarantee time?

A: 1 year, Main parts is made of high tool steel by special quenching treatment, with high corrosion resistance and wear resistance.

3. Q:What can you provide for after sale service?

A: We provide on the spot technical assistance in installation, commissioning and training if you need.

4. Q:If we have very special request for the production line,could you help me to do the design?

A:We provide experienced mechanical designer customized-design.

5. Q: If we have samples of new products, can you help to analysis and design the machine?

A:Yes, our technical department can help you analyze, design and test the new products you offer.