Пищевая промышленность фармацевтическая вакуумная лента фильтр

- Категория: Фильтровальная ткань >>>

- Поставщик: Shandong,Vinson,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.96 $* | 0.18 $* |

| Aug-16-2025 | 0.65 $* | 0.38 $* |

| Jul-16-2025 | 0.45 $* | 0.25 $* |

| Jun-16-2025 | 0.44 $* | 0.4 $* |

| May-16-2025 | 0.66 $* | 0.60 $* |

| Apr-16-2025 | 0.34 $* | 0.60 $* |

| Mar-16-2025 | 0.24 $* | 0.5 $* |

| Feb-16-2025 | 0.37 $* | 0.81 $* |

| Jan-16-2025 | 0.99 $* | 0.31 $* |

Характеристики

Food Industry Pharmaceutical Vacuum Belt Filter Cloth

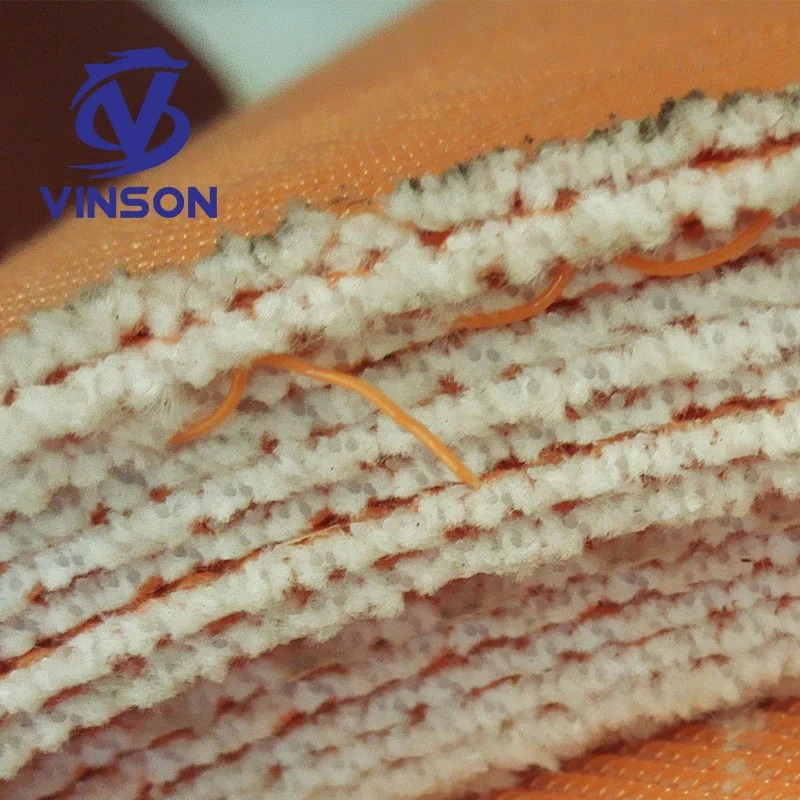

1- Monofilament-multifilament heavy filter cloth

2- Heavy monofilament filter cloth

3- Monofilament filter cloth

1- Monofilament-multifilament heavy filter cloth

Characters: Stable running, difficult shrinking, high wear resistance, accurate opening, and good filtration, it can be used in different rough conditions, especially applied to horizontal vacuum belt filters, and belt press filters.

Applications: FGD, petrochemical, mine, phosphoric acid, sylvine, citric acid,chemistry , aluminum catalyzer and etc

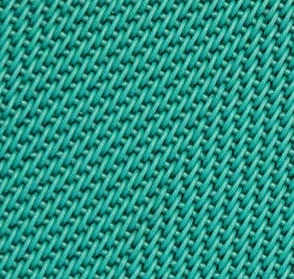

2- Heavy monofilament filter cloth

Characters: Rapid draining, good filter cake release, high wear resistance,heavy stability.

Applications: Sewage disposal, fruit juice compressing, food industries, chemical industries, because of high wear resistance and heavy stability of monofilament fabrics, it can be used as conveyor belts in food and chemical industries.

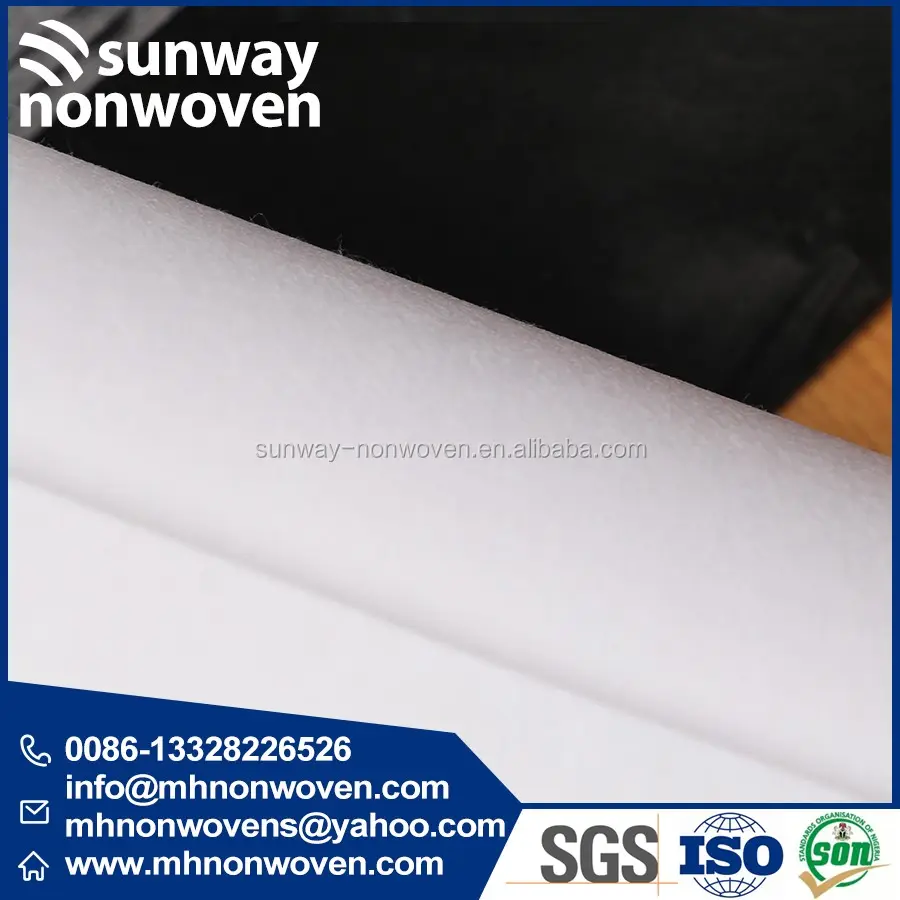

3- Monofilament filter cloth

Characters: Good air and water permeabilty easily prevent fabric bling, rapid peeling off, good regeneration; you will find a suitable fabric for each apicationand condition, thanks to its accurate openings and event air permeability.

Applications: Citric acid, lactic acid, glutamic acid, coal ash, carbon black water.active carbon, amino acid, dyestuff and intermediate, magnesium carbonate, catalyst and etc of food and chemical industries.

We will choose different fabrics which are resistant to acid, alkali, wearing, corrosion, rot, stretching, and high temperature, according to different conditions. High filtration precision and event air permeability guarantee the excellent filtration, and special weaving methods and thickness can avoid possibilities of shrinking, and ensure stable running, all above can extend the life of fabrics.

| Performance/Name | Polyeaster(PES) | Polypropylene(PP) | Polymide(PA) | Polyviny Alcohol |

| Acid Resistance | Good | Fair | Weak | Not Acid Resistance |

| Alkaline Resistance | Weak alkaline resistance | Good | Fair | Strong alkaline resistance |

| Breaking Extension | 20-50 | >PES | 20-40 | 12-26 |

| Breaking Strength | 4.3-9 | 4.5-9 | 4.5-9.5 | 4-10 |

| Soften Point | 238-260 | 140-160 | 180-235 | 220-230 |

| Melt Point | 255-260 | 165-173 | 215-260 | 220 |

| Specific Gravity | 1.38 | 0.91 | 1.14 | 1.26-1.30 |

| Wetness Resistance | 120℃ | 90℃ Shrink a little | 130℃ Shrink a little | 100℃ Shrink |

Fabrics choose standard

xxx=Good, xx=Fair, x=Weak

| Silk thread | Filter capacity | Degree of filtrate clarification | Filter cake release | Blocking resistance |

| Monofilament fabrics | xxx | x | xxx | xxx |

| Monofilament/multifilament fabrics | xxx | xx | xx | xx |

| multifilament fabrics | xx | xx | xx | xx |

| multifilament fabrics/spinning | x | xxx | x | xx |

| spinning | x | xxx | x | x |

| djule | xx | xxx | xx | x |

In May, 2010 the company passed the ISO90012008 international quality management system certification. The productions are widely applied in the horizontal vacuum belt filter, rubber vacuum belt filter, belt drier, belt filter press, press filter, HVPF Vertical automatic filter press and used in the industry of power plant, petroleum, chemical industry, smelting, mineral separation, environment protection, foods, and pharmacy. The company services for the manufacturers of national filtration-separation equipment suppliers and users. We will provide the best filtering plan for you, and our products and services have won the customer consistent high praise.

Related products

Vacuum belt fllter (also named fixed rubber belt vacuum fillter) Is a new solid-liquid separating equipment with high efficlency and continuous operation, based on introductlon, assimilation and digestion of the technlques of the same products overseas. It has achieved solid-liquld separation by making full use of material gravity and vacuum suction. In terms of its structure, filtering section is arranged horizontally lengthwise, and length of filtering section can be fully used to fulfill in turn such a process covering filtering, rinsing and sucking up, with advantages of high filtering efficlency, productivity, good rinsing effect, wide appllcation range, simple operatlon, stable running, convenlent maintenance and service.It is especially suitable for filtering suspension liquld feed pulp with coarse particle of solid phase, high density and requiring frequent washing of filter cake. It can be widely used forsolid-liquid separation in industrial sectors like metallurgy, mining, chemicals, paper-making, foodstuff, pharmaceuticals and environmental protection. It has special perfect application in gypsum dehydration in the course of flue gas desulfurization (FGD) by wet process.

Shandong Vinson machinery equipment co. LTD is a green technology design, product development, sales and services for the integration of science and technology, environmental protection equipment manufacturing company. Companies to provide solid liquid separation technology equipment, services, successively developed DU series of vacuum belt hydroextractor, DI series belt vacuum filter, HVPF series full automatic vertical plate and frame filter press, TC series ceramic vacuum filter and other solid-liquid separation and a number of solid-liquid separation of proprietary technology.

FAQ

Q1:Lead time.

A1:35 working days after receiving the prepayment.

Q2.Packing

A2:Carton or plywood sea worthy packages

Q3:Please confirm following before quotation or order

A3.:Ratio( input/output speed)

B. Drive power

C. Applied industry

D. Quantity

Q4:Warranty period

A4:One year, during the guarantee period, we will supply freely of the easy damaged parts for the possible problems except for the incorrect operation

Q5:OEM/ODM can be accepted?

A5:Yes, we can customize special application design and offer our professional advice, provide CAD & 3D drawings.