Rotary airlock valve for grain,wheat

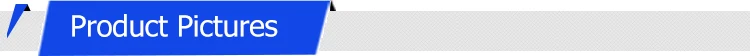

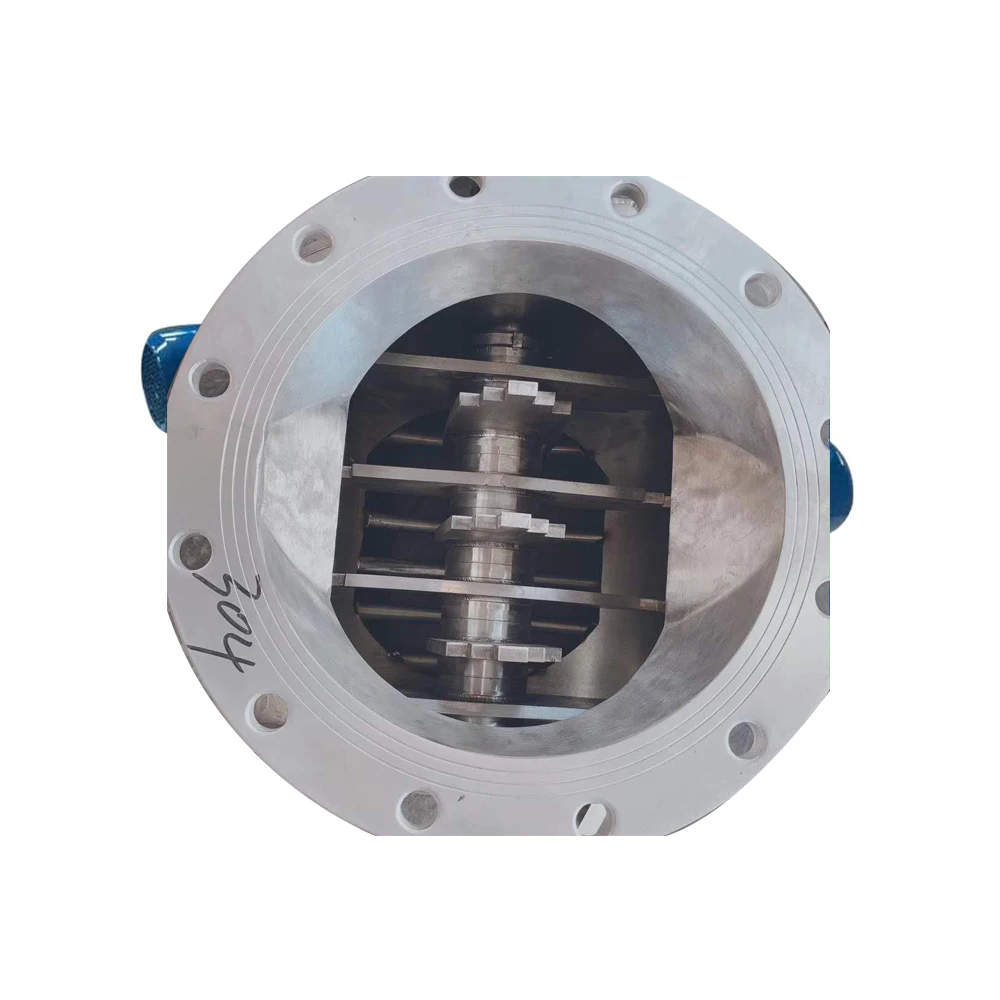

Rotary airlock valve consists of housing,rotor,bearing,speed reducer,motor and sealing elements

It provides a mechanically simple, efficient, and economical means to seal the discharge of dust filters and cyclones. The absolute minimum of moving parts enhances the efficiency and durability of the system.

A Rotary valve is robust-construction equipment designed to unload particulate or granulated material from silos, hoppers, pneumatic conveying systems, filters or cyclones.

The material to be unloaded enters the valve body and is driven by a rotor to the outlet mouthpiece in a cyclic and continuous movement, thus providing a regular flow of material.

The rotary airlock valve can be connected to other equipment the following way: the valve inlet and outlet have flanges where the valve can be connected to counter-flanges of other equipment by bolts.

Technical data of rotary airlock valve

NPS

|

DN

|

A

|

B

|

C

|

H

|

L

|

Temp

|

Speed

|

Power

|

Weight

|

6“

|

150

|

150

|

210

|

240

|

240

|

580

|

≤80C

|

24/

33/

40rpm

|

0.75

|

60kg

|

8“

|

200

|

200

|

260

|

300

|

350

|

690

|

0.75

|

95kg

|

10“

|

250

|

250

|

310

|

350

|

410

|

730

|

1.1

|

145kg

|

12“

|

300

|

300

|

360

|

400

|

440

|

820

|

1.5

|

250kg

|

![Spec-rotary valve]()

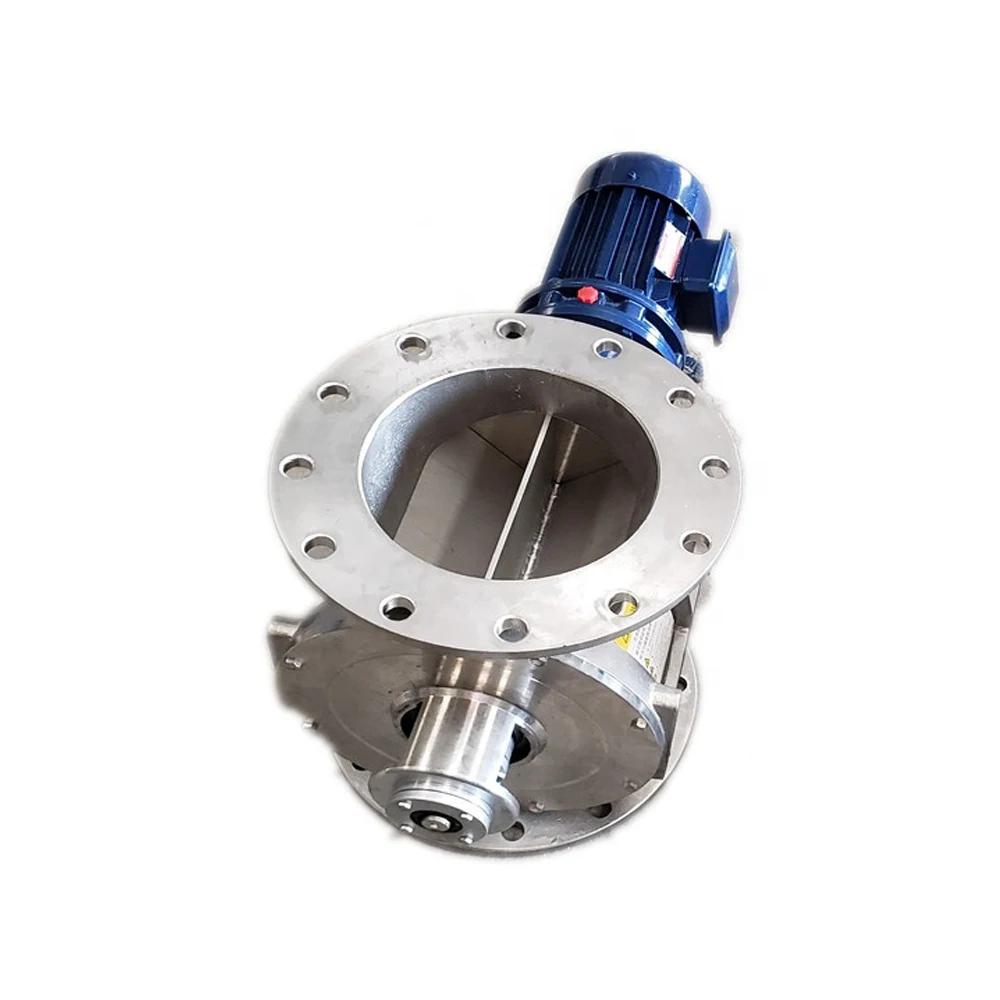

Application of rotary airlock valve

1.Chemical industry: resin, pigment, industrial medicine, cosmetic, coatings, medicine powder, granules.

2.Food industry: corn,wheat,sugar powder, starch, salt, rice, milk powder, egg powder.

3. Metallurgy, Mining industry: aluminum powder, copper powder, ore alloy powder, welding rod powder.

4. Medical industry: all kinds of medicine

5. Waste treatment: active carbon

|