Автоматическая роликовая формовочная машина для быстрой смены типа C Z ширина

- Категория: Обрешечивающие машины и машины для стальной рамы >>>

- Поставщик: Sussman,Machinery,(wuxi),Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-15-2025 | 5528603.90 $* | 5639175.66 $* |

| Jul-15-2025 | 4483828.37 $* | 4573505.61 $* |

| Jun-15-2025 | 5441539.13 $* | 5550370.51 $* |

| May-15-2025 | 5398006.44 $* | 5505966.91 $* |

| Apr-15-2025 | 4309699.74 $* | 4395893.51 $* |

| Mar-15-2025 | 5310942.64 $* | 5417161.17 $* |

| Feb-15-2025 | 5267410.27 $* | 5372758.95 $* |

| Jan-15-2025 | 5223877.95 $* | 5328355.94 $* |

Характеристики

Product Description

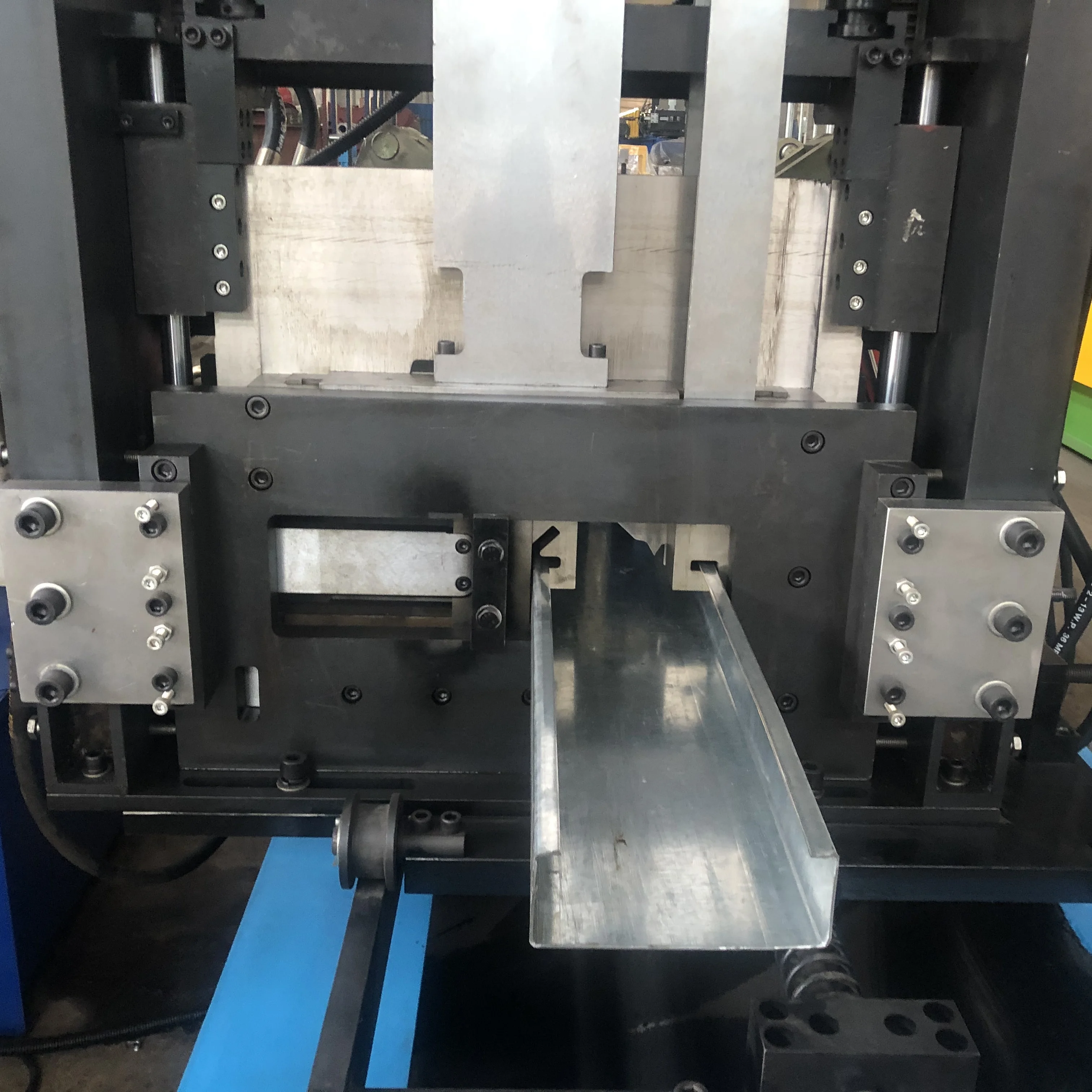

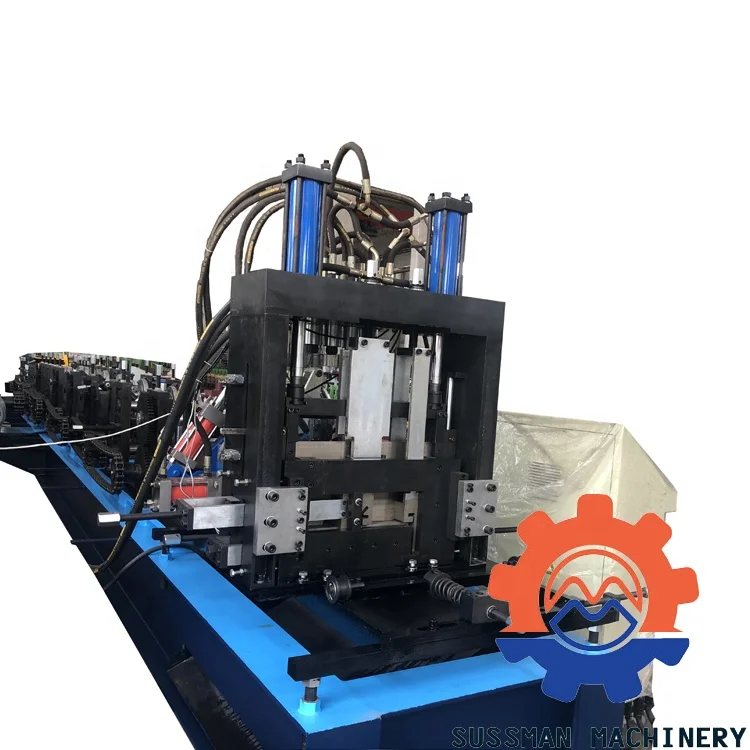

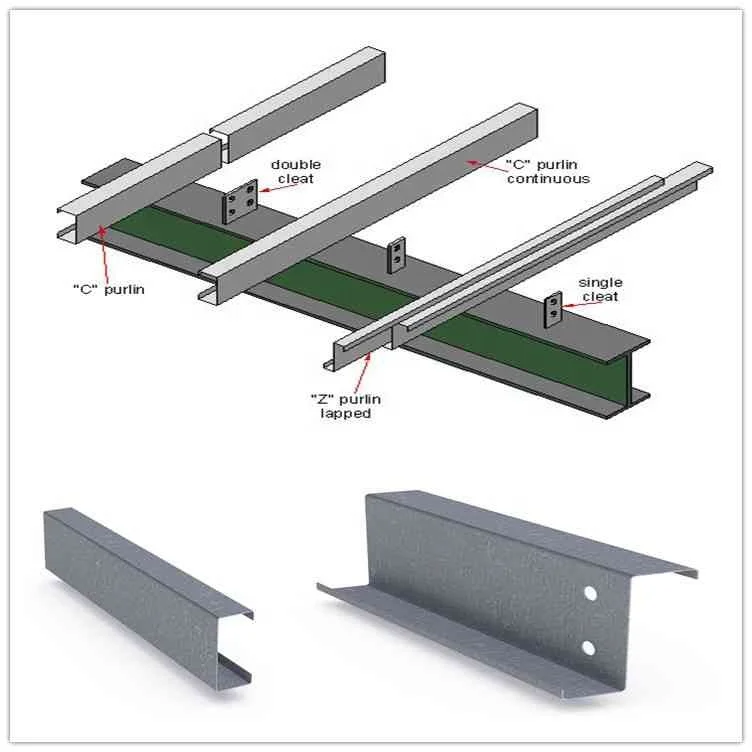

This C/Z Quick Interchangeable Roll Forming Machine adopts a special structure. The rollers for C&Z are changed very quickly without dismantle any parts . One machine can produce all specifications of C/Z/U purlins . Crimples are optional to increase rigidity of purlins. The width of the purlins can be automatically adjusted by PLC. If you need more economy then can be handle wheel adjusting as well. This machine we adopt Post-cutting and punching system, only need one cutting to make more size, the cutting blades can move up and down, left and right to save time to change blades.

C/Z Quick Interchangeable Machine | ||||||

No | Item | Specification | Optional | |||

1 | Suitable material | Type:Galvanized Coil, PPGI, Carbon steel Coil | ||||

Thickness(mm):1.5-3.0 | ||||||

Yield strength: 250 - 550MPa | ||||||

Tensil stress( Mpa):G350Mpa-G550Mpa | ||||||

2 | Nominal forming speed(m/min) | 10-15 | Or according to your requirement | |||

3 | Forming station | 18 | ||||

4 | Decoiler | Manual decoiler | Hydraulic decoiler or double head decoiler | |||

5 | Main machine motor | China famous Brand | Siemens | |||

6 | PLC brand | Panasonic | Siemens | |||

7 | Inverter brand | Yaskawa | ||||

8 | Driving system | Chain drive | Gearbox drive | |||

9 | Rollers’ materail | GCr15 | Cr12 | |||

10 | Station structure | Wall panel station | Forged Iron station Or torri stand structure | |||

11 | Punching system | Yes | Hydraulic punching station or Punching press | |||

12 | Cutting system | Post-cutting | Post- universal cutting | |||

13 | Power supply requirement | 380V 50Hz | Or according to your requirement | |||

14 | Machine color | Industrial blue | Or according to your requirement | |||

Profile Drawing

Application

Packing & Delivery

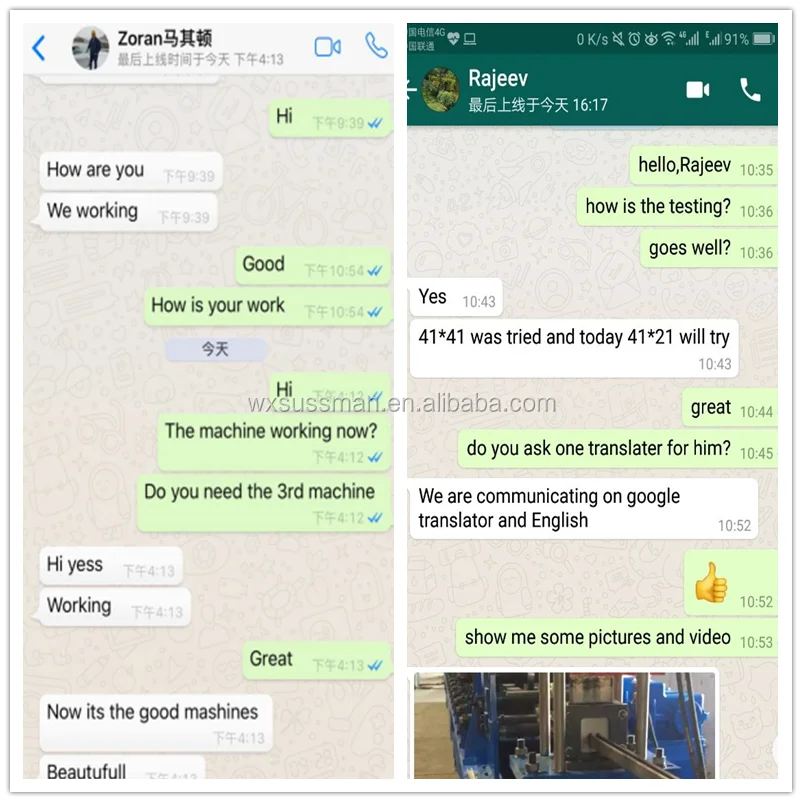

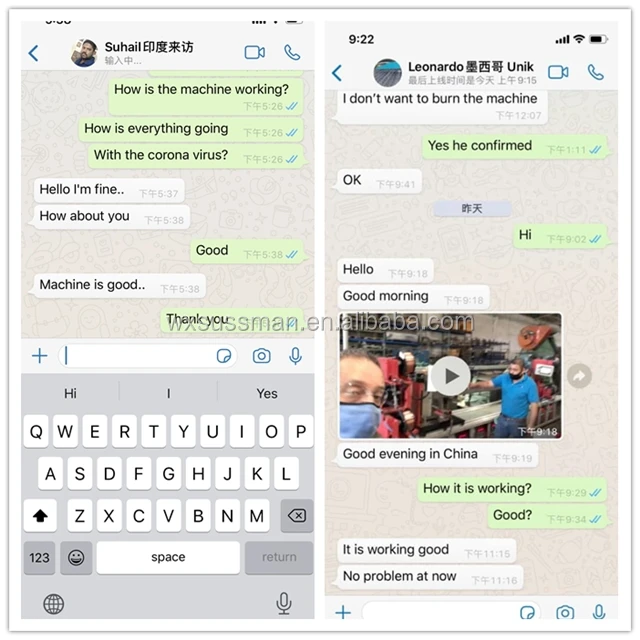

Customer's feedback

Maintance and the service of the machine

Machine maintenance

Daily maintenance with meticulous care plays an important part in extension the equipments’ operation time and the quality of rolling plank. Therefore, please do the following things in your daily.

1.The hydraulic tank must be filled with 32# or 46# hydraulic oil before using. The amount of oil is subject to the oil mark

2. Add and daub lube often to the outside parts. (Such as driving chain,Scissors, gears, rollers, )

3. Wipe the surface dust of roller often and particularly work outside. If you do not use it for long time ,you should daub

machine and lube in the roller surface and you need clean it when you use next time.

4. If the equipment does not use for long time, you should use plastics cloth or other articles to cover it and notice to avoid rain and damp, especially electrical controlling box

5. Cutting device should add lube to the places where need lube to the request

6. Usually look into hydraulic station and the oil quantity of deceleration machine, you should add in time when oil quantity shortage

7. Electrical components should be guaranteed to work in a dry environment, such as damp. Rain should continue to work after drying.

Daily maintenance with meticulous care plays an important part in extension the equipments’ operation time and the quality of rolling plank. Therefore, please do the following things in your daily.

1.The hydraulic tank must be filled with 32# or 46# hydraulic oil before using. The amount of oil is subject to the oil mark

2. Add and daub lube often to the outside parts. (Such as driving chain,Scissors, gears, rollers, )

3. Wipe the surface dust of roller often and particularly work outside. If you do not use it for long time ,you should daub

machine and lube in the roller surface and you need clean it when you use next time.

4. If the equipment does not use for long time, you should use plastics cloth or other articles to cover it and notice to avoid rain and damp, especially electrical controlling box

5. Cutting device should add lube to the places where need lube to the request

6. Usually look into hydraulic station and the oil quantity of deceleration machine, you should add in time when oil quantity shortage

7. Electrical components should be guaranteed to work in a dry environment, such as damp. Rain should continue to work after drying.

Company Profile

Sussman Machinery(Wuxi) Co., Ltd. is specialized in building materials of light steel structure. Since the factory founded 10 years before, it's always design and produce various type profile of roll forming machine.

The main products of factory is light gauge framing machine, pre-painted steel forming machine, Glazed Tile forming machine, Automatical C/Z Purlin forming machine, Floor Deck forming machine, Guardrail forming machine, Down Pipe forming machine, The whole carriage plate for car beam unit , Steel storage unit, etc. Totally it has 100 types in 20 serious. The products are widely used in warehouse, factory buildings, supermarket, Nursing homes, villas, residential, greenhouse and other construction projects. Our factory can meet the construction enterprises, automobile industry, iron and steel production enterprises's growing demand.

Company building area is over 5000 square meters, it has a highly efficient design, manufacturing, sales of high-quality team. The machine is coving in 30 provinces of China and worldwile.

The company always adhere to the "quality first, integrity first, service fast, continuous innovation" concept. Adoption of new technologies, development of new products, the application of advanced scientific management, and strive to make product quality better and better.

The company sincerely cooperated with the steel, car, the city of road&bridge construction industry field. The roll forming machine can be designed according to customer's profiles.

Thanks for the supporting and trust from the domestic and foreign customers. Our success is refine on and try to be better and better.

The main products of factory is light gauge framing machine, pre-painted steel forming machine, Glazed Tile forming machine, Automatical C/Z Purlin forming machine, Floor Deck forming machine, Guardrail forming machine, Down Pipe forming machine, The whole carriage plate for car beam unit , Steel storage unit, etc. Totally it has 100 types in 20 serious. The products are widely used in warehouse, factory buildings, supermarket, Nursing homes, villas, residential, greenhouse and other construction projects. Our factory can meet the construction enterprises, automobile industry, iron and steel production enterprises's growing demand.

Company building area is over 5000 square meters, it has a highly efficient design, manufacturing, sales of high-quality team. The machine is coving in 30 provinces of China and worldwile.

The company always adhere to the "quality first, integrity first, service fast, continuous innovation" concept. Adoption of new technologies, development of new products, the application of advanced scientific management, and strive to make product quality better and better.

The company sincerely cooperated with the steel, car, the city of road&bridge construction industry field. The roll forming machine can be designed according to customer's profiles.

Thanks for the supporting and trust from the domestic and foreign customers. Our success is refine on and try to be better and better.

Exhibition

Похожие товары

Гидравлический разматыватель

US $7500-$9500

Силос прогонами машина низкая цена

US $43000-$45000

Машина для прокатки холодных секций c purlin

US $21000-$22000