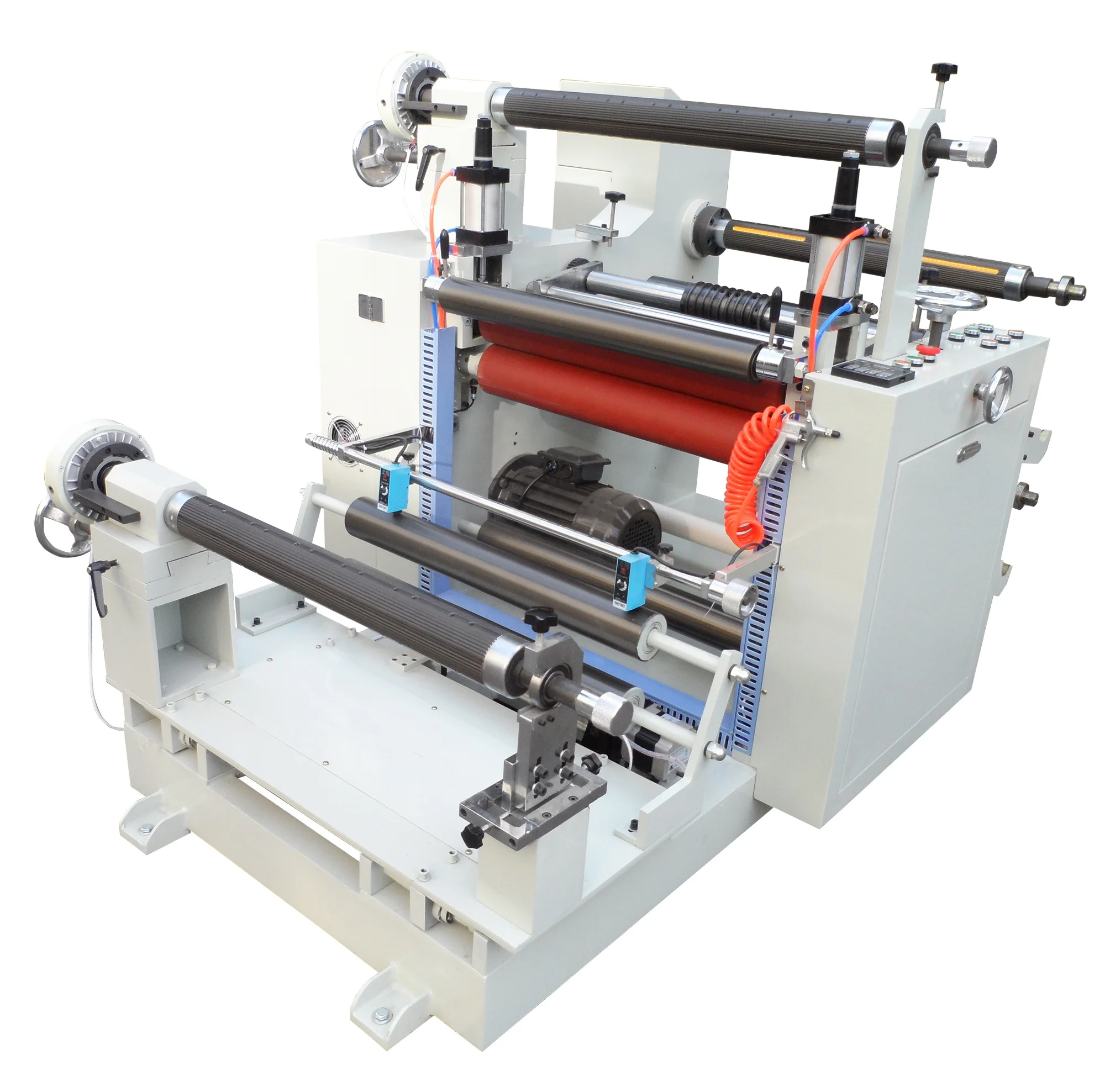

Устройство для продольной резки резины толщиной 2 мм

- Категория: Другое оборудование для обработки резины >>>

- Поставщик: Kunshan,Yidao,Precise,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.99 $* | 0.29 $* |

| Aug-16-2025 | 0.95 $* | 0.23 $* |

| Jul-16-2025 | 0.32 $* | 0.35 $* |

| Jun-16-2025 | 0.58 $* | 0.50 $* |

| May-16-2025 | 0.50 $* | 0.79 $* |

| Apr-16-2025 | 0.40 $* | 0.50 $* |

| Mar-16-2025 | 0.63 $* | 0.17 $* |

| Feb-16-2025 | 0.4 $* | 0.25 $* |

| Jan-16-2025 | 0.73 $* | 0.82 $* |

Характеристики

"with us your MONEY in safe ; your BUSINESS in safe"

YIDAO FACTORY OFFER YOU :

1: FACTORY DIRECT PRICE.

2: NICE QUALITY.

3: NO MOQ ,1PC OK.

4.ONLINE PAYMENT.

5.SUPPORT 7 DAYS REFUND.

WELCOME TO BE ONE OF OUR TOP "VIP" CUSTOMERS". WE BELIEVE THAT " THE QUALITY IS THE SOUL OF AN ENTREPRISE".

WELCOME TO CONTACT US.

Machine features:

This machine employs photoelectric track and rectification system, and the magnetic powder clutch is adopted to control the feeding and rewinding tension. Main machine adopts frequency conversion speed regulation. The movement of the rubber roller is controlled by the cylinder. laminating and slitting be done at one time , laminating or slitting can be done separately. Accurate slitting, fast speed, easy to operate and maintenance.

Technical parameters:

Item No. | YD-650FQ |

Slitting Speed | 80m/min |

Max. Web Width | 650mm |

Max. Unwinding Diameter | 600mm |

Max. Rewinding Diameter | 450mm |

Slitting Precision | ±0.1mm |

Total Power | 2.2KW |

Machine size | 2400*1700*1300mm |

Machine Weight | 1000Kgs |

Voltage | 220V 50HZ |

*the voltage can customize according to your country standards.

Characteristics and Functions:

1.Machine frame made of coated steel

2.Electronics integrated in the machine frame

3.unwinding with pneumatic compressed shaft for 3" cores

4.rewinding with pneumatic compressed shaft for 3" cores

5.Web tension adjustable via magnetic powder clutch

6.Blower fan for suction of waste strip

7.unwinding is controlled by two photoelectric eyes

8.The movement of the rubber roller is controlled by cylinder

9.Laminating and slitting can be done at one time or separately.

Standard configuration:

1.One slitting station

2.One laminating station

3.With one piece 3'' unwinding shaft,2 pieces rewinding shafts

4.With meter/number counter

5.With two photoelectric eyes

6.With 10 sets of round slitting knives

7.Machine has blower fan to blow away the trimmed edge

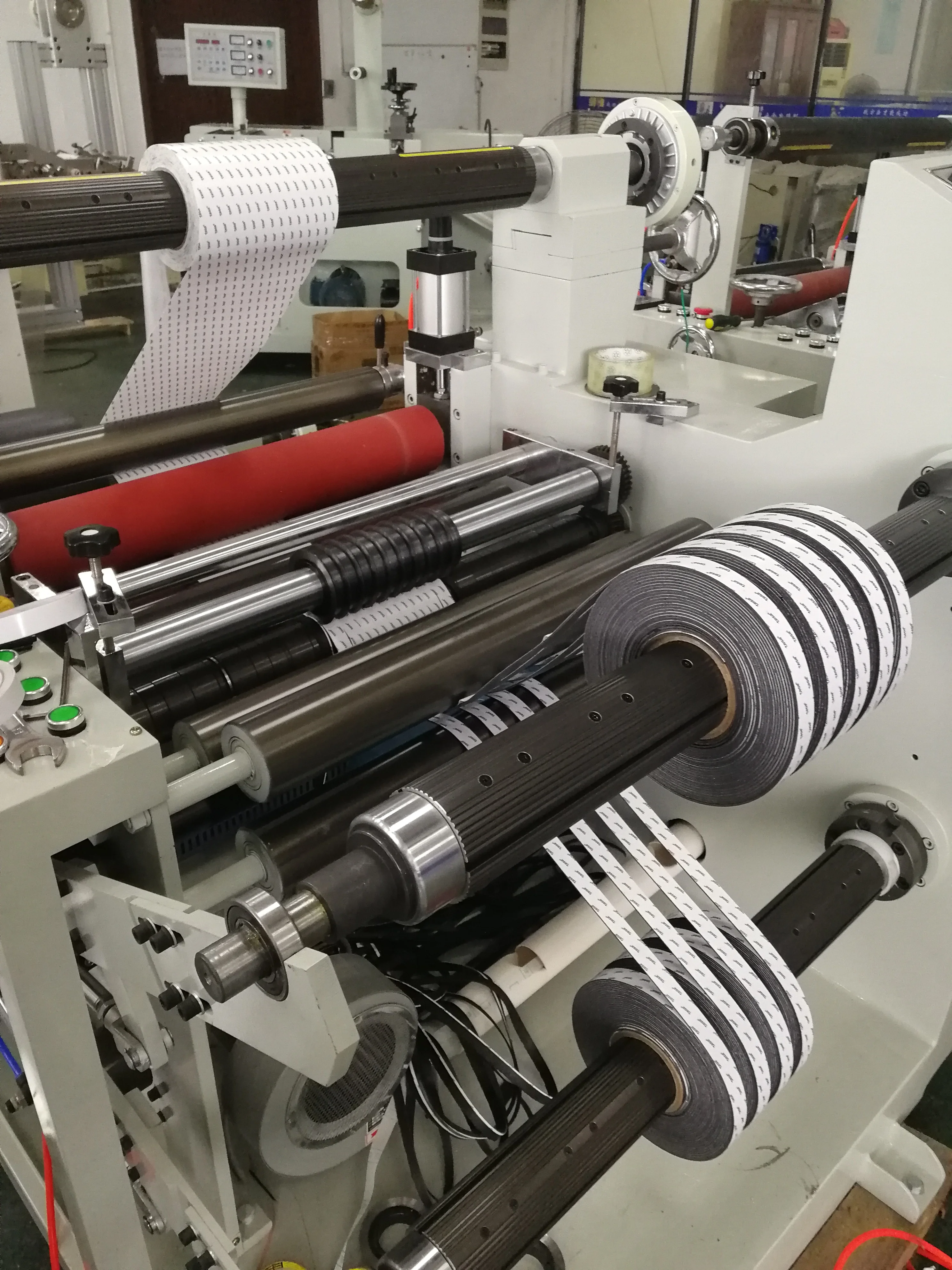

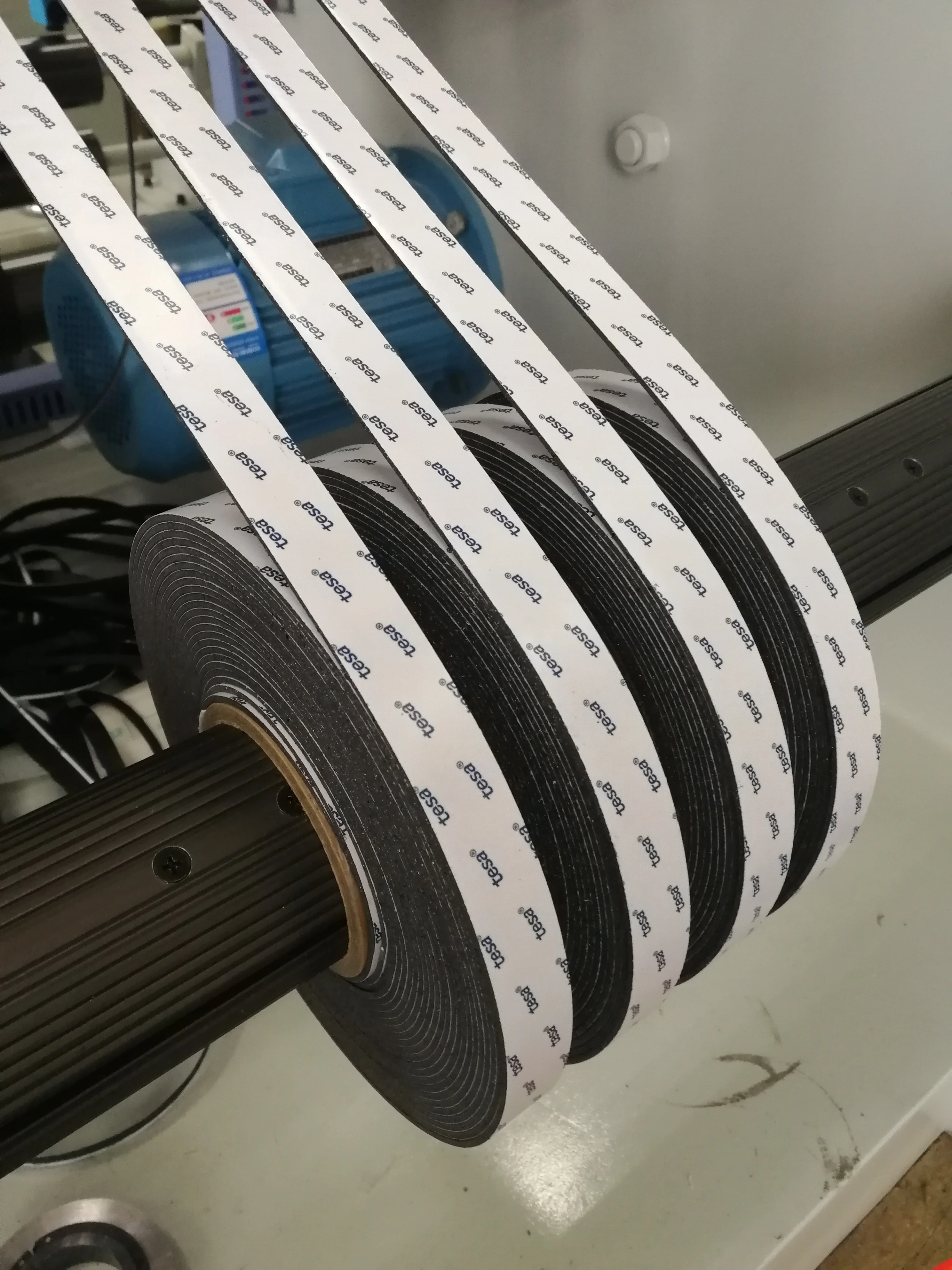

Application:

1. It is applicable for the slitting tooling of industrial adhesive tape, electronic material, protective film, fiberglass,copper foil, aluminum foil, OPP, PE, PVC, PP,sheet, cloth, Flannelette etc.

2. This machine is widely used in the industries such as printing, packing, electronics, leather, clothes making, plastic, etc.

Control Panel

You can set slitting speed,running length,unwinding and rewinding tension on it.

It is very easy for worker to operate the machine.

Slitting Blades

This machine is standard equipped with 10 sets of slitting blades,the min slitting width is 15mm.if you want to slit smaller width,you can customize self-lock knives.

It's easy to adjust the slitting width based on your products.

Magnetic powder Brake/clutch

Unwinding and rewinding tension adjustable via magnetic powder brake/clutch.

You can set the tension on the control panel according to your material and requirements.

Edge/line Position Controller

These electrical photo sensors is used to guide the non neat material.to make sure the slitting rewinding effect is good.

The photo sensors focus on the edge of material,you can choose to use single sensor or double sensors.

1. Training Service

We can train your staffs how to run the machine efficiently and safely.

1.1 Free training in our factory available before delivering machines.

1.2 We also can arrange engineer to customer's plants for installation and training.

2. After Sales Service

We offer not only the products, but also the solutions.We have plenty of cooperated professional supplier which make it possible for us to offer our customers big convenience to complete their production line in high quality with low cost in a short time.

For all of our machines, we provide:

1. Operation Manual, Operation and repair Video.

2. 1 year guarantee, whole life technical support .we also offer some spare parts packing together with the machine.

3.24hours Email technical support, we will do our best to help the clients solve problems.

4.Available to send our engineer to clients factory, to install the machines, train the workers, repair the machines.

PACKAGE: we use plywood case for packing the machine to make sure wooden case safe and strong, up to International trade standard. It does not need Fumigation .It's easy for forklift to upload and download .Safety transportation .we will use PE film for packing first before plywood case or pack it according to customers special .

SHIPPING : Usually we suggest customers choose ocean shipping to ship machinery , or air transport for small machine and urgent order . We also supply shipping sevice with our cooperation shipping forwarder to help customers to deliver the machinery in first time .