5 мм 6 8 10 FRP Стекловолоконный твердый круглый стержень И

- Категория: Другие изделия из стекловолокна >>>

- Поставщик: Dongguan,Sanchuang,Composite,Materials,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.23 $* | 0.28 $* |

| Aug-17-2025 | 0.38 $* | 0.57 $* |

| Jul-17-2025 | 0.65 $* | 0.46 $* |

| Jun-17-2025 | 0.59 $* | 0.81 $* |

| May-17-2025 | 0.14 $* | 0.96 $* |

| Apr-17-2025 | 0.9 $* | 0.50 $* |

| Mar-17-2025 | 0.92 $* | 0.24 $* |

| Feb-17-2025 | 0.6 $* | 0.18 $* |

| Jan-17-2025 | 0.47 $* | 0.25 $* |

Характеристики

Product Description

Product features:

1.High Strength

2.Low Deformation Rate

3.High HDT

4.Low Hydroscopicity

5.Low Thermal Insulation Coefficient

6.Anti-corrosion

7.Anti-aging

8.Insulation

Product Specification:

Currently,we have made many fiberglass rods in different sizes these are not only have the exsiting moulds but also some stocks,hereby,listed as follow.If they are some just suitable for you,the mould cost as well as the cycle time can be reduced largely.What's more,a few samples can be probided free for your test first.Anyway,if you have some other specs required,customizing is always available and the most welcome.

Physical Properties Of Ordinary Fiberglass Profiles | ||||||||

NO. | Testing items | Unit | Testing results | Testing standard | ||||

1 | Density | g/cm3 | 1.8-1.9 | GB/T5130_1997 | ||||

2 | Hydroscopicity | % | 0.37 | GB/T5130_1997 | ||||

3 | Flexural strength (perpendicular to fiberglass direction) | MPa | 705 | GB/T5130_1997 | ||||

4 | Flexural modulus (perpendicular to fiberglass direction) | MPa | 2.3×10000 | GB/T5130_1997 | ||||

5 | Tensile strength (Parallel to fiberglass direction) | MPa | 581 | GB/T5130_1997 | ||||

6 | Electric strength (perpendicular to fiberglass direction) | MV/m | 4.2 | GB/T5130_1997 | ||||

Product process:

Pultrusion process is a kind of method to make composite profiles continuously, which using the twistless roving with other continuous reinforced composites, polyester surface mat,ect. to proceed the resin impregnation, then go through the forming mould with same section, and make the continuous depanning after curing un the intramode. Thus, the pultrusion products come out by this automatic production process.

Packing & Delivery

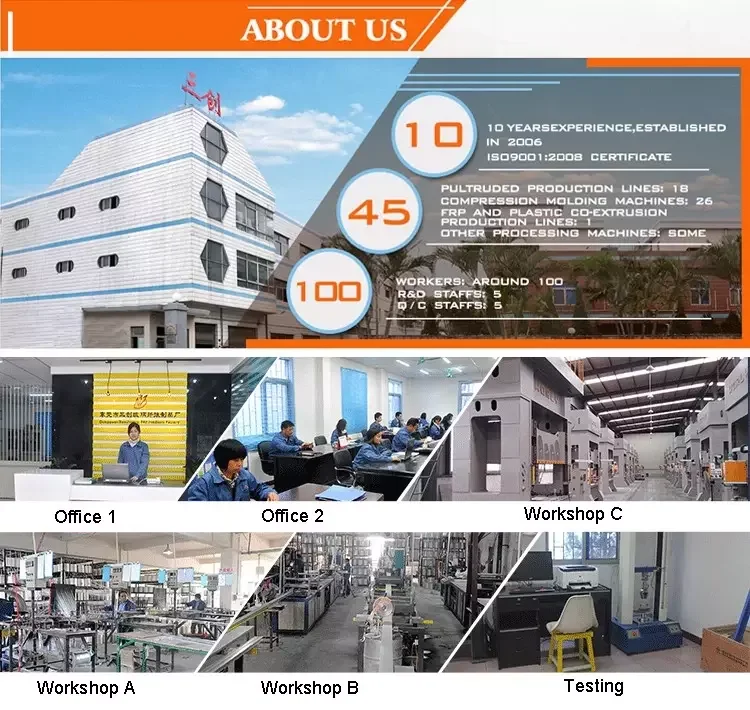

Our Company

Sanchuang Composite Material Technology Co., LTD. is a research and development, production and sales of composite technology enterprises.

The main products include:

Fiberglass and carbon fiber pultrusion profiles

SMC/BMC/DMC molding products

RTM products

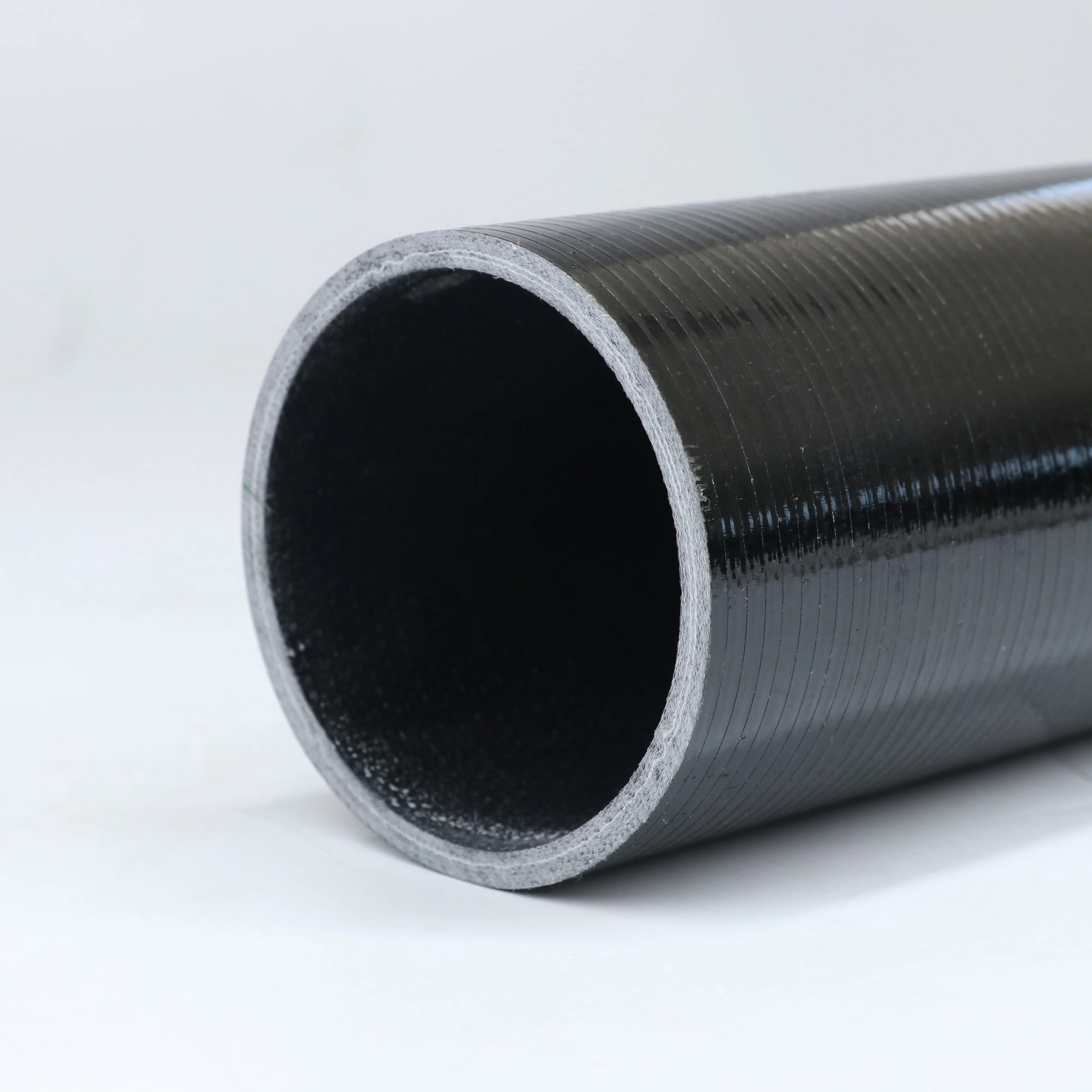

Winding molding tubes

High-quality hand lay-up products

At present ,our company provide products and services for the United States, Canada, Germany, United Kingdom, France, Italy, Spain, Denmark, Netherlands, Sweden, Hungary, Bulgaria, Mexico, Australia, Japan, South Korea, Vietnam, Philippines, Egypt etc. more than 35 countries and over 120 customers .

Our Tenet: Creating Excellence, Innovation, Honesty

Fiberglass and carbon fiber pultrusion profiles

SMC/BMC/DMC molding products

RTM products

Winding molding tubes

High-quality hand lay-up products

At present ,our company provide products and services for the United States, Canada, Germany, United Kingdom, France, Italy, Spain, Denmark, Netherlands, Sweden, Hungary, Bulgaria, Mexico, Australia, Japan, South Korea, Vietnam, Philippines, Egypt etc. more than 35 countries and over 120 customers .

Our Tenet: Creating Excellence, Innovation, Honesty

Certifications

Customer Photos

Recommend Products

FAQ

Q:What is FRP?

A:Fiber Reinforced Polymer (FRP) is a composite material made of a polymer matrix reinforced with fibers. The fibers are usually glass, carbon, aramid, or basalt. Our common resins are unsaturated resins, vinyl resins and epoxies. FRPs are commonly used in the aerospace, automotive, marine and construction industries.

Q:Are you a trading company or a manufacturing factory?

A:Our company is a reasearch and development, production and sales of composite technology enterprises.The main products inculde the fiberglass and carbon fiber pultrusion lines, SMC/BMC compression molding production lines, SMC/BMC moulds products lines, SMC/BMC moulds production lines and other supporting production lines. We own strong capablity about product development that based on exploration about the raw materials and production process.

Q: How do you guarantee the quality of your products?

A: Our products will be tested before delivery. In order to control quality, we use high quality materials.

Q: I am interested in your products, could I get sample for free?

A: We could supply a few pieces of free samples if we have some in stock. You need to offer your shipping account and pay the freight cost .

Q:Can you do the design for us?

A: Yes.We can customize specific moulds to make products according to the drawings you provide. We can make products of different specifications, shapes, colors and sizes.

Q: When is the delivery time?

A: It depends on the quantity of the order. Normally, 10-15 working days after receipt of your deposit and confirmation of all details.

Q: If I increase the number of orders, what preferential terms can you give me?

A: The price depends on the quantity ordered. The larger the quantity ordered, the larger the discount.

For more information, please feel free to contact us.

Похожие товары

Стекловолоконные обрезки/Отходная пряжа для гипсокартона

US $0.70-$0.80

Гибридные ткани из базальтового волокна

US $3.80-$4.00

Высокопрочная термостойкая Стекловолоконная труба/столб/труба

US $19.00-$24.00