180 мм ширина высокой точности 4 строгальный станок для

- Категория: Рубанок по дереву >>>

- Поставщик: Shandong,STX,Machinery,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.25 $* | 0.91 $* |

| Aug-17-2025 | 0.39 $* | 0.92 $* |

| Jul-17-2025 | 0.33 $* | 0.2 $* |

| Jun-17-2025 | 0.90 $* | 0.33 $* |

| May-17-2025 | 0.53 $* | 0.54 $* |

| Apr-17-2025 | 0.51 $* | 0.61 $* |

| Mar-17-2025 | 0.70 $* | 0.90 $* |

| Feb-17-2025 | 0.65 $* | 0.51 $* |

| Jan-17-2025 | 0.47 $* | 0.8 $* |

Характеристики

180mm Width High Precision 4 Side Planer Moulder for Woodworking

Main Features

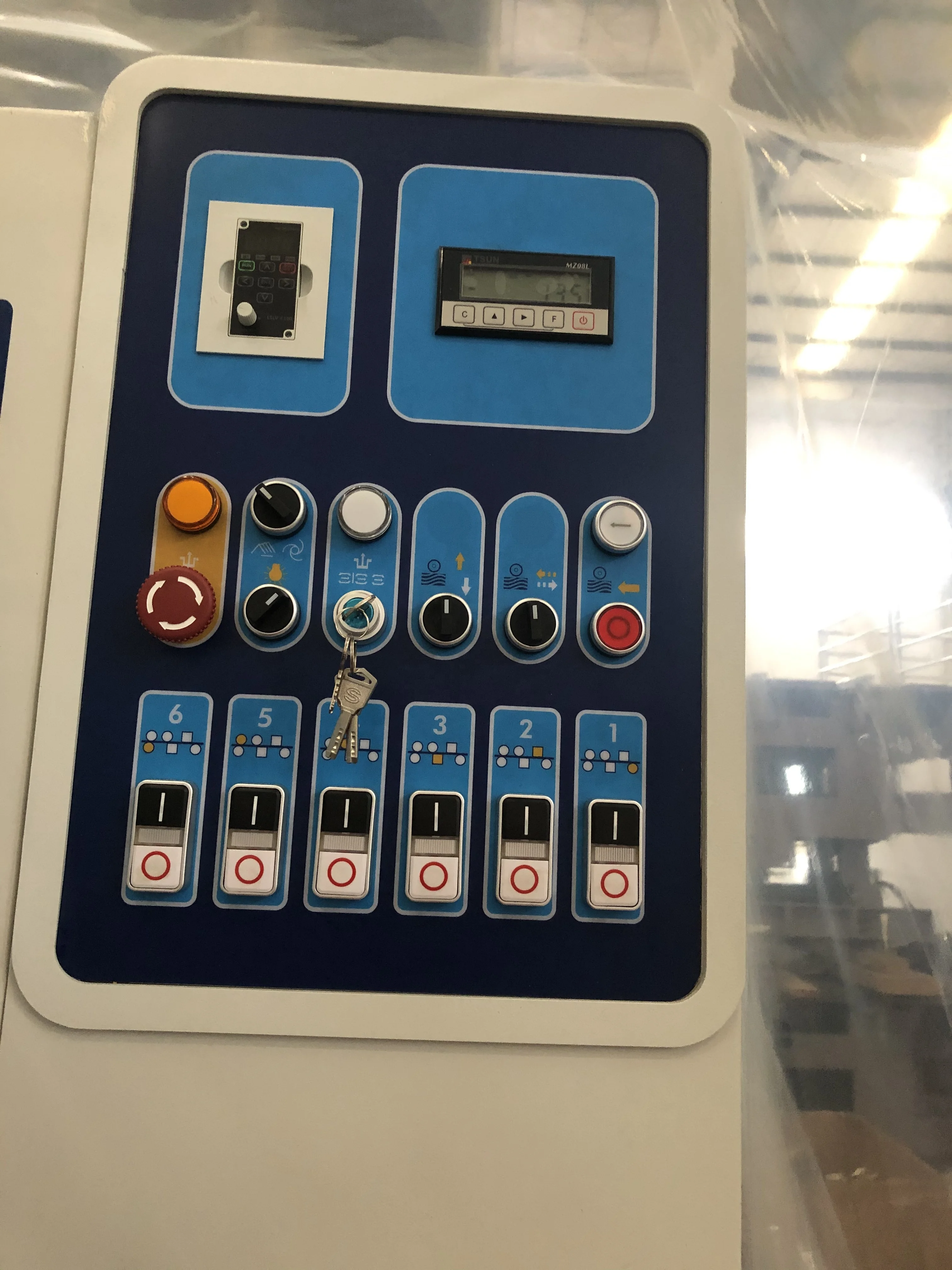

1.Stepless speed regulation with the feeding speed of 7-28 M / min

2.Each spindle driven by an independent motor with strong cutting force

3.Electroplating countertops with good wear resistance

4.The lower initiative rollers improves the feeding effect

5.Fully enclosed safety shield, effectively avoid sawdust flying and isolate noise

6.Pneumatic feeding wheel adjust the clamping force sectionally ensure smooth feeding of wood profile with different thickness

7.Configured auxiliary device for short profile

Parameters

Processing Capability | |||

| Model NO. | M618 | M518 | M418 |

Working width | 25-180mm | 25-180mm | 25-180mm |

Working thickness | 8-130mm | 8-130mm | 8-130mm |

Length of working table | 1500mm | 1500mm | 1500mm |

Feeding speed | 6-36m/min | 6-36m/min | 6-36m/min |

Spindle diameter | 40mm | 40nn | 40mm |

Spindle speed | 6500r/min | 6500r/min | 6500r/min |

Air pressure | 0.6MPa | 0.6MPa | 0.6MPa |

Motor Power | |||

The 1st lower shaft | 4.0kW | 4.0kW | 4.0kW |

The right vertical shaft | 4.0kW | 4.0kW | 4.0kW |

The left vertical shaft | 4.0kW | 4.0kW | 4.0kW |

The 1st upper shaft | 5.5kW | 5.5kW | 5.5kW |

The 2nd upper shaft | 4.0kW | ---- | --- |

The 2nd lower shaft | 4.0kW | 4.0kW | --- |

Lifting beams | 0.55 kW | 0.55kW | 0.55kW |

Feeding | 3.0kW | 3.0kW | 3.0kW |

The total power | 29.05kW | 25.05kW | 21.05kW |

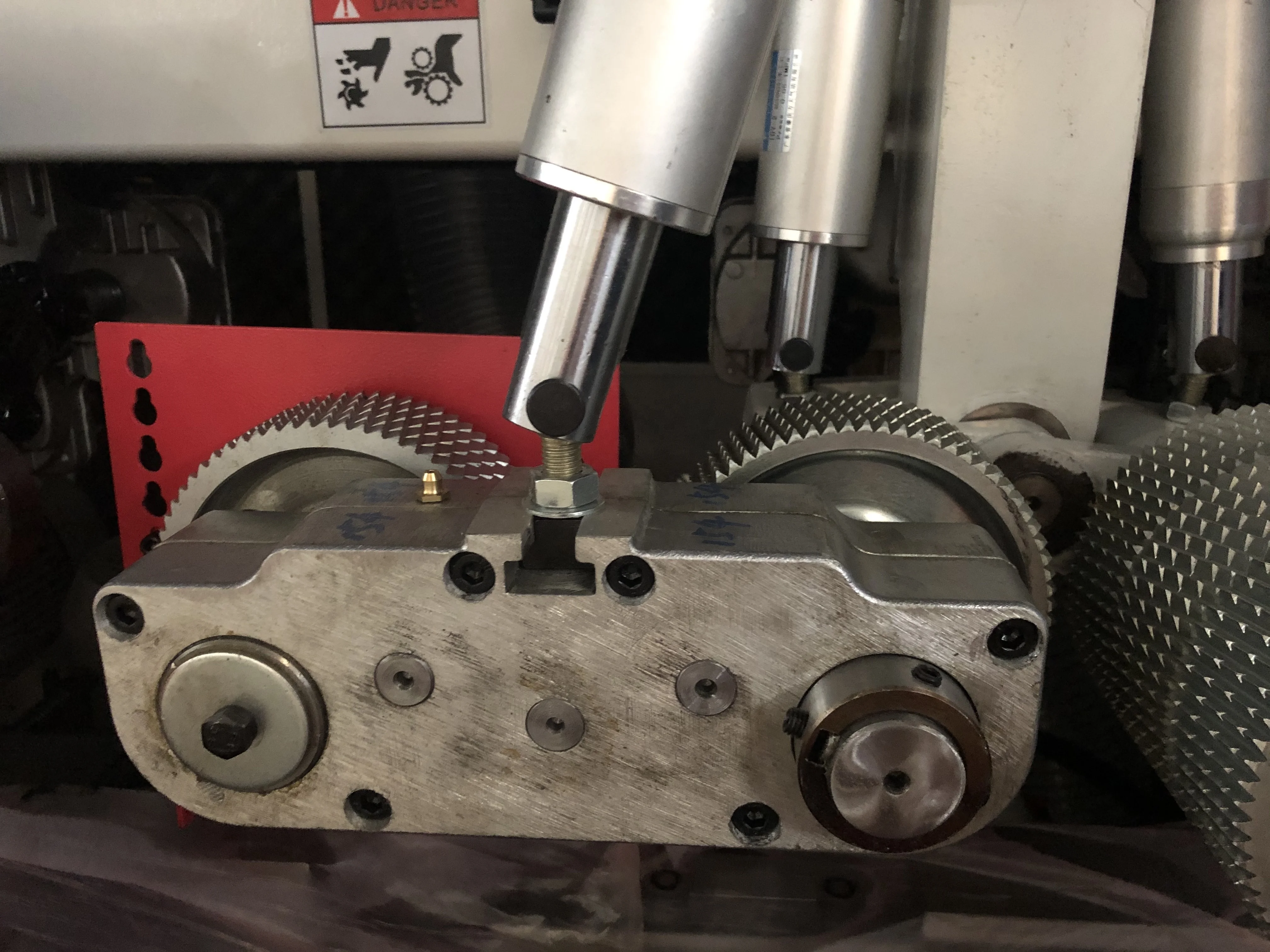

The universal chainless transmission for feeding materialsis precise, strong, long life, no need for maintenance for years.

Front and rear press plate can be adjusted respectively, although the big variation in wood thickness, also work pieces can be firmly pressed down on the working table.

Every main shaft must strictly be tested for dynamic balance, ensuring the smooth running of the cutter shaft.

Double-deck working table on left and right spindle, guaranteed working verticality.

After passed the quality inspection, the machine will be wiped with biodegradable anti-rust oil to protect from the humid sea air. Then use PE film packaging.

Usually we use iron pallet handling equipment to the container. It can also be packaged in a fumigant-free wooden box according to customer requirements.

Pre-sale Service

· Tailored configuration solutions according to your needs.

· Customized service available.

· Free workshop layout design.

· Free visit reception service.

· Free supply chain support service.

After-sales Service

· Professional on-site installation, training and maintenance.

· Timely and efficient online and video technical support.

· Super 18 months warranty since package opened.

· Reliable lifetime spare parts support and technician service available.

Since established in 1990s years, we keep our attention on Four side moulder, Double Side Moulde, Rip saw,Optimizing cross cut saw and double end tenon machine. Depand on powerful R&D capability, strong machining capacity and high quality products and service, we have becoming a leader manufacturer in China.