ZJR-10 PLC контроля косметический крем делая машину вакуумная эмульсионная лаборатории

- Категория: Mixing Equipment >>>

- Поставщик: Wuxi,YK,Automation,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 8568.68 $* | 8996.74 $* |

| Aug-17-2025 | 8496.46 $* | 8921.23 $* |

| Jul-17-2025 | 7128.97 $* | 7484.9 $* |

| Jun-17-2025 | 8352.60 $* | 8770.97 $* |

| May-17-2025 | 7272.18 $* | 7636.49 $* |

| Apr-17-2025 | 8208.33 $* | 8618.12 $* |

| Mar-17-2025 | 8136.93 $* | 8543.24 $* |

| Feb-17-2025 | 8064.12 $* | 8467.75 $* |

| Jan-17-2025 | 7992.20 $* | 8392.69 $* |

Характеристики

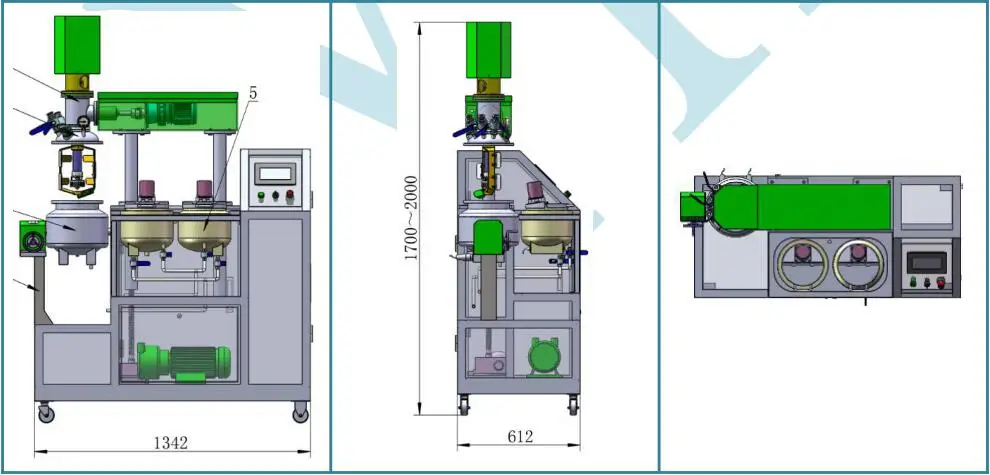

It is an automatic lifting type for the lid of emulsification tank with the main tank invertible and dumpable.

The emulsification tank comes with a high shear homogenizer and a counter-rotating scraper.

It includes 2 pre-treatment tanks. One is the water phase tank, the other is the oil phase tank.

A high speed dispersion system exists inside the pre-treatment tank.

There is a vacuum system inside the emulsifying equipment with the working materials in the pre-treatment pot able to be sucked into the emulsification tank using the negative pressure.

They are mirror polished for both inner and outer surfaces of the tank to meet the sanitary requirements.

It adopts the electric heating method through the jacket layer, resulting in uniform heat transfer and high accuracy of

temperature control. Moreover, the system can be connected to the water supply for cooling.

Customers can select the control mode alternatively using the PLC or button.

Advantages

Suitable for high viscosity materials with the highest viscosity up to 80,000MPas.

Good emulsification effect & stable emulsion form, the particle size of the micro-droplets is usually less than 5um.

The main tank can be dumped and discharged through the bottom valve.

Includes a vacuum system that can form a high vacuum value above -0.093MPa in the emulsification tank.

The parts in direct contact with the working material are made of high quality stainless steel 316.

The heating temperature is controlled by PID with the features of fast heating and high accuracy of temperature control.

A heat insulation layer is provided outside the heating jacket to prevent the operator from being burned.

It comes with LED lighting inside tank and sight glass with scraper.

It is easy to clean and maintain for the machine structure.

A lot of anti-daze and other protection mechanisms are set inside the equipment to avoid personnel injury and accidental damage to the equipment as much as possible.

Other functions can be customized.oratory Use High Shear Vacuum Emulsifier Mixer for Sale

ღ Application:

There are three pots : Main pot (Emulsifying pot) and preparatory pots (Water pot and Oil pot).

The water pot and oil pot are preparatory pots. For products which need emulsifying, the raw materials are always including water phase material and oil phase material, so the water pot is for preparation of water phase materials, and oil pot is for preparation of oil phase materials. The two pots both have jacket layer, which can be heated by electrical heating or steam . Meanwhile, the two pots equip with mixing system. The mixing system is dispersing disk with speed of 1400 rpm. After preparing (feeding, heating, mixing), the raw materials in these two pots can be absorbed into the main pot (emulsifying pot) by the power of vacuum through pipeline.

NAME | ZJR-5 | ZJR-10 | ||

Emulsifying pot | Design Volume(L) | 6 | 10 | |

Capacity(L) | 5 | 8 | ||

Scraper Stirring Power(kw) | 0.55 | 0.55 | ||

Scraper Stirring Speed(rpm) | 0-86 | 0-86 | ||

Homogenizer power(kw) | 1.1 | 1.1 | ||

Electrical heating power(kw) | 2 | 2 | ||

Homogenizer speed (rpm) | 3500 | 3500 | ||

Water pot | Design Volume(L) | 3.35 | 7.8 | |

Capacity(L) | 2.7 | 6 | ||

power(kw) | 0.025 | 0.025 | ||

speed(rpm) | 1200 | 1200 | ||

Electrical heating power(kw) | 1 | 1 | ||

Oil pot | Design Volume (L) | 3.35 | 7.8 | |

Capacity (L) | 2.7 | 6 | ||

power (kw) | 0.025 | 0.025 | ||

speed (rpm) | 1200 | 1200 | ||

Electrical heating power (kw) | 1 | 1 | ||

Dimension | Length*Width*Height | 800mm*550mm*1430mm | ||

About us, click below to know more...

ღ About YK >

ღ R&D >

ღ Our Customers >

ღ Our Factory >

ღ Our Service >

ღ Our Suppliers >

ღ Honor & Certificates >

ღ Company TIMELINE >

Packaging:

packing by wooden case usually, we also do other packaging as per customer's requirement.

Shipping:

- European Countries: 22-28 days

- United States: East --13-16 days, West--21-28 days

- Brazil: 30-40 days

- Russia: 36 days

- Asia Countries: 3-5days

1. Why your machine similar with other supplier?

We are an overseas-funded enterprise. We are manufacturer and had been in this industry for more than 17 years, with more than 9 years export experience. We design machines by ourselves with advanced technology. Appearance just a part of machine, Service and quality is more important than it.

2. I'm new in our industry, but I'm planning to set up a factory, What can I do?

We can suggest customer the most suitable machine according to their formula, Raw material. Manufacturing- Installation- Training- Maintenance- Technical Support. We can introduce you supplier of raw material, bottles, labels etc. We could take you to our customer's factory to learn how they produce. We could customize machines according to your real need, We could send our engineer to your factory to install machines and train your worker of Operation and maintenance. Any more requests. Just let us know.

Applications

(1) Cream, paste Products

In cosmetic industry: face cream, body cream, washing cream,hand cream etc

In food industry industry: sauce, ketchup, tomato paste, mayonnaise, mustard, chocolate etc

In chemical industry:welding paste,ink, paint,pigment etc.

Production line for them: RO water treatment- vacuum emulsifying machine- storage tanks- filling machine-capping machine- labeling machine- conveyor belt- inkjet printer- sealing machine-shrinking machine etc

(2) Liquid products

shampoo, lotion, liquid soap, detergent, juice, solution, etc.

Production line for them: RO water treatment - liquid wash mixer- - storage tanks- filling machine-capping machine- labeling machine- conveyor belt- inkjet printer- sealing machine-shrinking machine etc

(3) Make-up products:

Lipstick, lip gloss, nail polish, mascara, etc

Machines for them: homogenizer mixer, colloid mill, lipstick filling machine, freezing machine, etc

(4) Adhesive products:

Instant glue, AB glue, silica gel, anaerobic adhesive, silicon, sealing etc.

Machines for them: double planet mixer, ribbon blender, tube filling and sealing machine, hydraulic distributing machine, cartridge filling machine, etc.