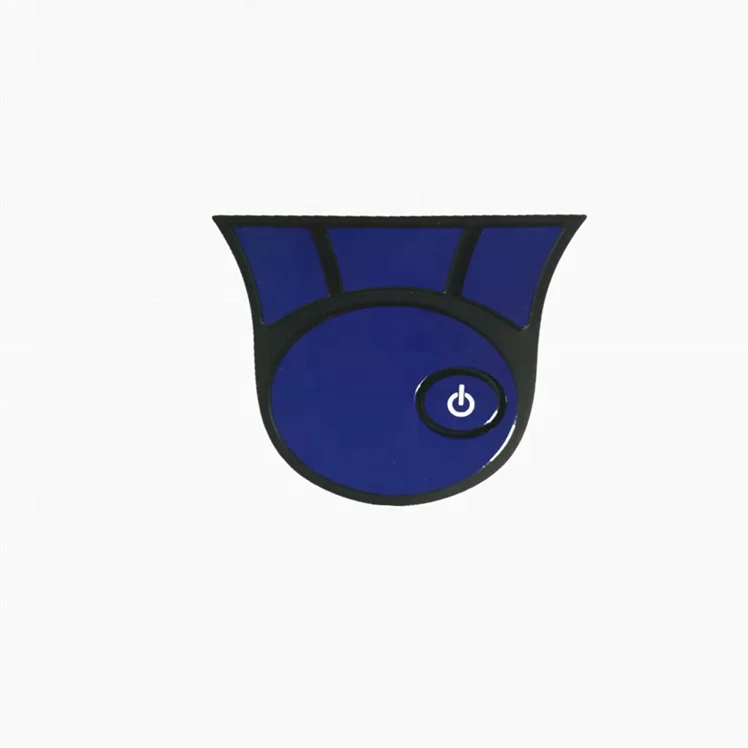

Глянцевые синие силиконовые резиновые колпачки для кнопок бытовой

- Категория: Электронные аксессуары и принадлежности >>>

- Поставщик: Guangzhou,Jianming,Electronic,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-16-2025 | 1.55 $* | 1.41 $* |

| Jul-16-2025 | 1.65 $* | 1.47 $* |

| Jun-16-2025 | 1.17 $* | 1.42 $* |

| May-16-2025 | 1.90 $* | 1.64 $* |

| Apr-16-2025 | 1.78 $* | 1.89 $* |

| Mar-16-2025 | 1.88 $* | 1.28 $* |

| Feb-16-2025 | 1.28 $* | 1.24 $* |

| Jan-16-2025 | 1.87 $* | 1.54 $* |

Характеристики

Silicone Rubber Keypads:

Silicone Rubber Keypads are manufactured from elastic, nontoxic silicone rubber compounds and are processed from compression or injection molding. The result is an economical and reliable keypad for small, medium and large production runs. Silicone keypads can be integrated with printed circuit boards or flexible circuits and have excellent resistance to temperature and aging.

Uniontech can also integrate your rubber keypad solution with a graphic overlay, printed circuit board (PCB), membrane ½ switch to allow additional flexibility in your design.

BASE MATERIAL:

The natural color of raw silicone rubber material is translucent white. Raw materials are blended with silicone-based color pigments to obtain the color required. Phosphorescent materials can be blended with the base rubber to create a “glow-in-the-dark” effect.

Durometer is one of several ways to indicate the hardness of a material. It defines the material’s resistance to permanent indentation. It is named for instrument maker AlbertF.Shore, who developed a measurement device called a durometer in the 1920s. The term durometer is often used to refer to the measurement, as well as the instrument itself. Durometer is typically used as a measure of hardness in polymers, elastomers and rubbers.

Suggested hardness for silicone rubber keypads is 40 to 60 Shore A depending on your requirements for actuation force, tactile response and life. Higher hardness rubber keypads offer higher actuation force and snap ratio but shorter life. Lower hardness rubber keypads have lower actuation force and snap ratio but longer life. Silicone rubber is available in flame classifications of UL94HB and UL94V0. The flame classification of most silicone rubber used for keypads is UL94HB.

COMPARISON OF SHORE A DUROMETERS:

25 Shore A | Rubber band |

40 Shore A | Pencil eraser |

55 Shore A | Door Seal |

65 Shore A | Tire Tread |

100 Shore A | Hard skateboard wheel |

Dual Durometer solutions are also available. In this construction, a higher (harder) durometer rubber is used for the key top and a lower (softer) durometer rubber is used for the base.

PRINTING, MOLDING AND HARDCOATING:

Silkscreen printing

Graphics can be applied directly to the keytops of the rubber keypad by screen printing. Multiple colors may be printed, with each color requiring an additional process. The optimum keytop for printing is a flat keytop. However, some curved keytops can also be printed.

Spray paint and laser etch

After the translucent rubber is molded into the keypad shape, the entire top surface of the keypad is spray-painted with one or more colors. A laser is used to etch graphics on the keytops to expose either an underlying layer of paint or the raw rubber. When backlit, light will pass through the translucent rubber and be visible in the etched areas.

Two-shot molding

Similar to Dual Durometer, a keypad can be produced using one color of rubber for the key top and a separate color for the base.

Flow molding

This process allows specific areas of a keypad to be molded with different colored rubber. This provides different base colors without requiring complicated spray-paint techniques. Silk screening is typically done on top of these base colors to provide additional graphics.

Key caps

Premolded hard plastic keytops can be applied to the molded rubber keypad. This provides a hard key feel with the economies and efficiencies of a rubber keypad.

PU coating

Silicone rubber keypads can also be spray-coated with PU resin to provide absolute lifetime abrasion resistance and oil resistance. This important technique has already been successfuly developed.

Hard coating

A screen-printing or spray-painting process is used to apply an additional protective clear silicone ink on the keytops. This increases the abrasion resistance of the printed graphics.

Epoxy coating

Silicone rubber keypads can be coated with a layer of epoxy resin to form a hard top and feel like plastic. The epoxy coating also provides additional abrasion resistance for the printed graphics.

Conductive contacts

Silicone rubber keypads can be co-molded with carbon impregnated silicone pills (carbon pills), gold -plated pills and metal pills according to the application requirements. Due to the low cost of production and acceptable resistance (less than 100 ohms), most rubber keypads are co-molded with carbon pills.

FEATURES:

• Light pipes

• Abrasion-resistant coating

• Epoxy capped

• Laser etching

• Positive or negative printing

• Fluorosilicone

• Glow-in-the-dark

• Variety of colors

Rubber Keypad Membrane Switches:

A custom silicone rubber keypads are an inexpensive and reliable interface solution for many applications. They offer design flexibility with a wide range of appearance, feel and function. Environmental sealing ribs, light pipes and other attributes can be incorporated into the keypads design. They can provide the tactile feedback and contact closure or be used in conjunction with metal and polyester domes.

Certain features can also be incorporated on the design of the rubberized silicone keypads such as sealing ribs, light pipes and other features.

Silicone Rubber Keypads design options:

1. Silicone Molded

2. Laser Etched

3. Parylene or Polyurethane Coating

4. Epoxy Coating

5. AG paste, FPC, PCB structure/Tactile, non-tactile /Key profile, travel and force

6. Embedded LED’s, Resistors & sensors & Backlit .

7. Able to make to customer’s waterproof requirement & UV protection design

8. Fiber Optic & Electroluminescent Backlighting & Environment

9. ESD Anti-Static Design: using Aluminum Foil, Printing AG or C plasma , ITO Film anti-static

Conductive options:

Molded conductive pill in carbon from 1.5mm to 10mm in diameter. Silver, gold and oval shapes are also available.

Printed conductive pills can be used for irregular shaped contacts, such as "ring" for LED backlighting in individual keys.

Markings:

Screen printed

Painted and laser etched

Chemical and Wear resistant coatings:

Silicone spray overcoat doubles the abrasion resistance of printed graphics.

Polyurethane spray coating can increases abrasion resistance of graphics by 20X.

Clear epoxy drip on key tops for a hard plastic feel or lens effect.

Parylene coating for resistance to most chemicals.

One of the most common features found in almost all household electronics these days are silicone rubber keypads. They are considered as an economical and highly reliable user interface solutions found in almost all types of applications. There are several design options for rubberized silicone keypads (of which attributes to the flexibility of the keypad).

Silicone rubber keypads work by creating momentary contact once a particular key or button is pressed. The contact is then disconnected when the pressure of the key or button is released. The key or button returns to its neutral position once the pressure is released.

Silicone rubber keypads are commonly found on remote controls and on control panels of various electronic household products such as television sets, audio and video products, electronic toys and as a user interface for numerous industrial equipments. Most of today's mobile phones and hand held gadgets use silicone rubberized silicone keypads as means to manipulate and access certain features of the device or gadget.

The markings of the rubberized silicone keypads are used to identify the function of certain buttons or key. They are mainly printed, painted or etched on the button or key of the device or gadget or electronic product. Rubberized silicone keypads are very durable and are known to be resistant to certain chemicals. They have wear resistant coatings, which makes them more resistant to wear and tear.

surface gloss blue silicone rubber keycaps push button for home appliance

FAQ

1.Are you a manufacturer or trading agent?

We are a high-tech manufacturer and have 15 years experience on producing Touch Screens(Touch Panel) , TFT LCD(liquid crystals display), membrane switches, Flexible Printed Circuit Board (FPC or flexible PCB), Graphic Overlays, Silicon Rubber Keypads, PCB(printed circuit board) Designs, Plastic Housings, Printed Labels, Decals , Aluminium Parts and more.

2.Can you offer samples?

(1)Stock Samples: If you paid the freight cost, we can provide free samples for you.

(2)Customized Samples: We will offer you 5 pcs free samples after we receive the tooling charge cost.

3. What is the delivery time?

(1)Customized sample: About 5 to 10 working days.

(2)Mass production: About 10--15 working days.

4. Is the prototype necessary?

Yes.Most of the items are customized orders,so the prototype will be sent to customer for approval.

5.What is the MOQ?

Generally, we require 50pcs for MOQ or USD200 for equivalent.

6. What is the terms of payment?

As the client need,we mainly receive trade assurance,TT,west union,PayPal etc.