Лист для листа гофрированный картон автоматическая высекальная машина резки с Creas decупа картонная

- Категория: Оборудование для пресса >>>

- Поставщик: Cangzhou,Quanheng,Imp,&,Exp,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 59500.51 $* | 62475.98 $* |

| Aug-19-2025 | 59000.32 $* | 61950.56 $* |

| Jul-19-2025 | 49500.24 $* | 51975.22 $* |

| Jun-19-2025 | 58000.88 $* | 60900.69 $* |

| May-19-2025 | 50500.1 $* | 53025.75 $* |

| Apr-19-2025 | 57000.62 $* | 59850.80 $* |

| Mar-19-2025 | 56500.13 $* | 59325.48 $* |

| Feb-19-2025 | 56000.66 $* | 58800.50 $* |

| Jan-19-2025 | 55500.64 $* | 58275.15 $* |

Характеристики

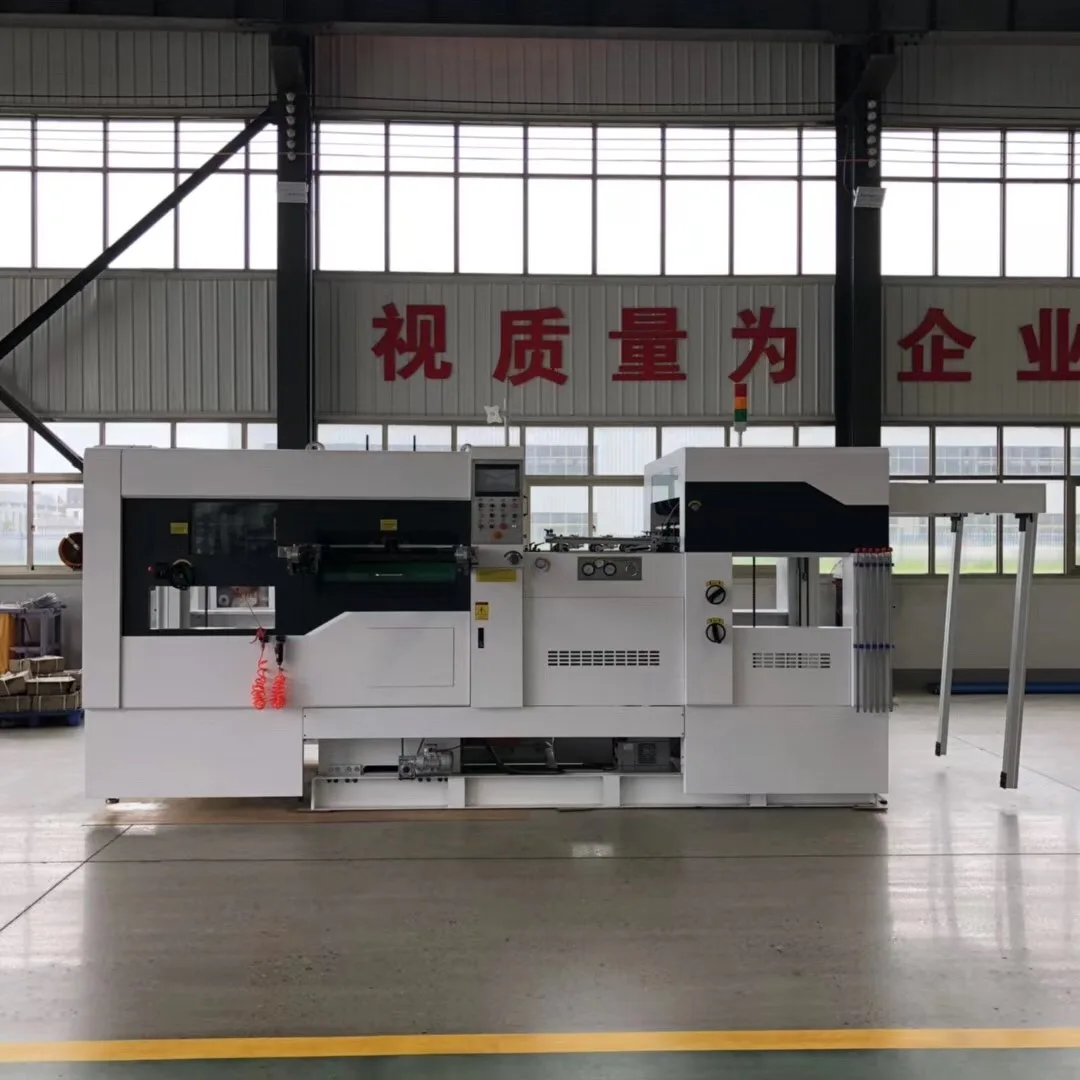

MY1300/MY1500/MY1650 Automatic Die Cutting and Creasing Machine with Auto Stripping

Item | Parameters |

|

Model | MY-1300 | |

Die cutting type | Pressed flat die cutting(Lower side is | |

movable while upper side is unmovable) | ||

Max paper transmitting size | 1320*980mm | |

Min paper transmitting size | 400*500mm | |

Max die cutting size | 1300*960mm | |

Min gripper size | 8mm | |

Max die cutting pressure | 350N/cm² | |

Paper processed | Cardboard | 200-2000 gsm |

Corrugated board | less than 6mm | |

Max die cutting speed | 4600 sheets/h |

|

Max feeding pile height | 1400mm(above the level) | |

Min feeding pile height | 1250mm(above the level) | |

Main motor power | 11 kw | |

Total power | ~18 kw | |

Total weight | 16.5 T | |

Overall size | 6500*2300*2346mm | |

(without platform and pre-paper) | ||

7900*4300*2346 | ||

Lead edge feeder(Under suction feeder)

Equipped with lead edge feeder ,it can prevent the cardboard damage by the black wheels.

Independent servo actuator can assure the cardboard send to right position and avoid crash on the paper

The big power suction fan and the adjusted wind system work for 3-9mm corrugated box.

Feeding table

Adjustable brush wheels and pressing wheels to ensure precise position to enter into front and side lay

Advance push and pull lay of registration can assure the die cutting precision

Rikko light front lay detection system prevent the slanting paper move in main body

The lifting of the brush wheel frame is controlled by cylinder.Easy to operate.

Main body

Adopt automatic centralized lubricating system and setting main chain lubricating system by HMI

Patented design shock absorption system can prolong the life of main body and increase the pressure

The intermittent gearbox made in Taiwan can assure the accurate registration and decrease the gripper attack

Die cutting part and Delivery system

Die cutting chase fixed accurately by pneumatic lock system

Diecutting plate is putted in and out by air floating device

Electric clutch system of main chain can assure the chain steady when it is stopped at high speed

Main chain and assist chain is lubricated periodically controlled by PLC

Protection window of diecutting can hold the main body clean

Lightweight and durable aluminum alloy 7-piece gripper bars with chain of Renold UK or Iwis ensure accurate

Q:Are you manufacture or trading company?

A:we are manufacture , our factory set up on 1999, and before we exported our products are mainly supply to the trading company ,

so we are the source factory, welcome to be our agency.

Q:Do you inspect the finished products?

A:Yes, we have QC department, they will inspect the machine before shipping, to ensure there is nothing problem of the machine .

Q:Does the packing strong?

A:Yes, of course! All of our export packing with strong wooden tray, all to meet the export packaging standards.

Q:How about after-sales service process?

A:When your machine has problem, contact our sales and we will solve your problem as soon as possible.We have after-sale office in

China, Vietnam, India, Bangladesh, Italy.

Q.Where is your factory?

A:Our factory located in Development Zone, East Of DongGuang County, CangZhou City, Hebei Province,China,welcome to visit our

factory!

Q. Do you have Import & export right?

A:Yes , we have , so we can export the carton machines to you directly , without any trading company agency.