Ультратонкие 0 2 мм 3 4 5 7 1 высококачественные закаленные листы боросиликатное стекло на

- Категория: Стекло >>>

- Поставщик: Xinyu,Xu,Tking,Glass,Co.,ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-16-2025 | 1.10 $* | 1.18 $* |

| Jul-16-2025 | 1.67 $* | 1.1 $* |

| Jun-16-2025 | 1.41 $* | 1.72 $* |

| May-16-2025 | 1.67 $* | 1.0 $* |

| Apr-16-2025 | 1.97 $* | 1.57 $* |

| Mar-16-2025 | 1.11 $* | 1.71 $* |

| Feb-16-2025 | 1.70 $* | 1.57 $* |

| Jan-16-2025 | 1.74 $* | 1.33 $* |

Характеристики

Product Description

Introduction:

A particularly low coefficient of thermal expansion is what makes BOROFLOAT® glass remarkably resistant to high temperature levels. Our borosilicate glass is proven to stand up to high and fluctuating temperatures typical of applications such as high-performance lamps, cinema projectors and inspection panels for chemical reactors. Even with applications where rapid cooling down from higher temperatures is the requirement, BOROFLOAT® glass easily passes the test. For example, the temperature difference between a hot panel center and a cold panel edge.

Outstanding thermal resistance

Very good temperature stability

Excellent resistance to thermal shock

Can be thermally toughened

Can be thermally shaped (3D)

Thermal properties

Coefficient of Linear Thermal Expansion (C.T.E.) α (20 - 300 °C)\t3.25 x 10-6 K-1 *

Specific heat capacity cp (20 - 100 °C)\t0.83 kJ/(kg·K)-1

Thermal conductivity λ (90 °C)\t1.2 W/(m·K)-1

* According to ISO 7991.

Maximum operating temperatures

For short-term usage (< 10 h)\t500 °C

For long-term usage (≥ 10 h)\t450 °C

Viscosity of BOROFLOAT® 33

Working Point (104 dPas)\t1270 °C

LITTLETON temperature / Softening Point (107,6dPas)\t820 °C

Annealing Point (1013 dPas)\t560 °C

Strain Point (1014,5 dPas)\t518 °C

Transformation temperature (Tg)\t525 °C

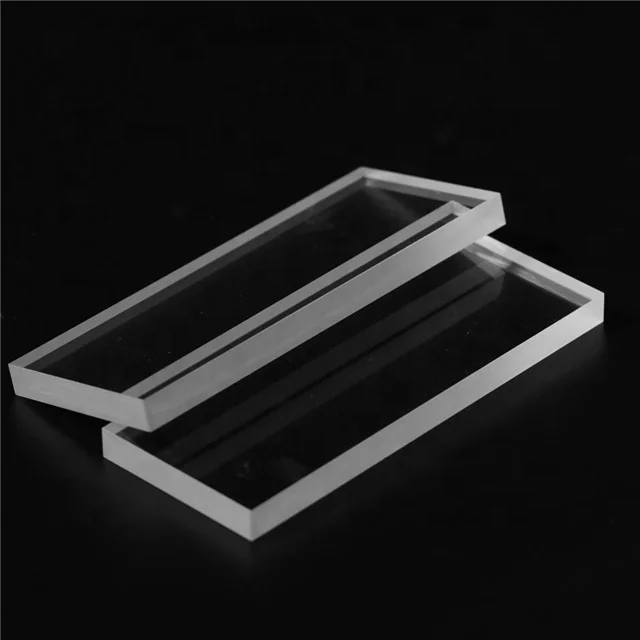

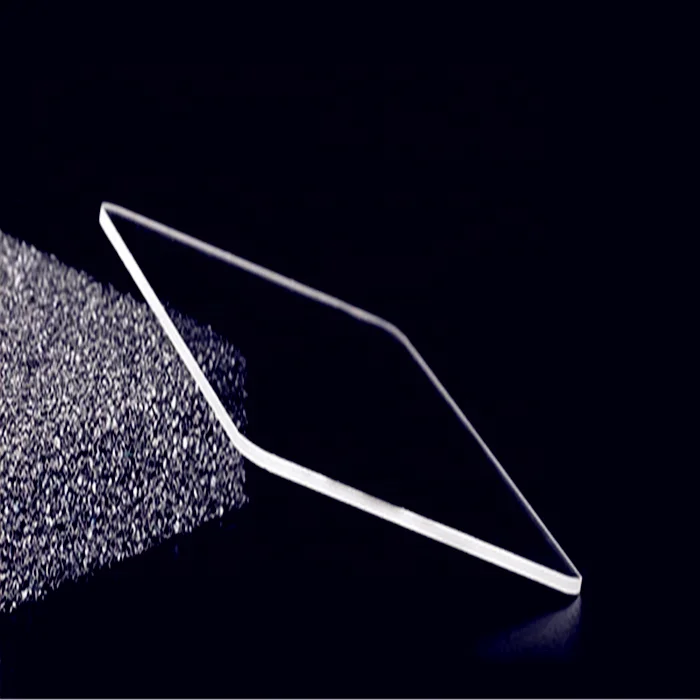

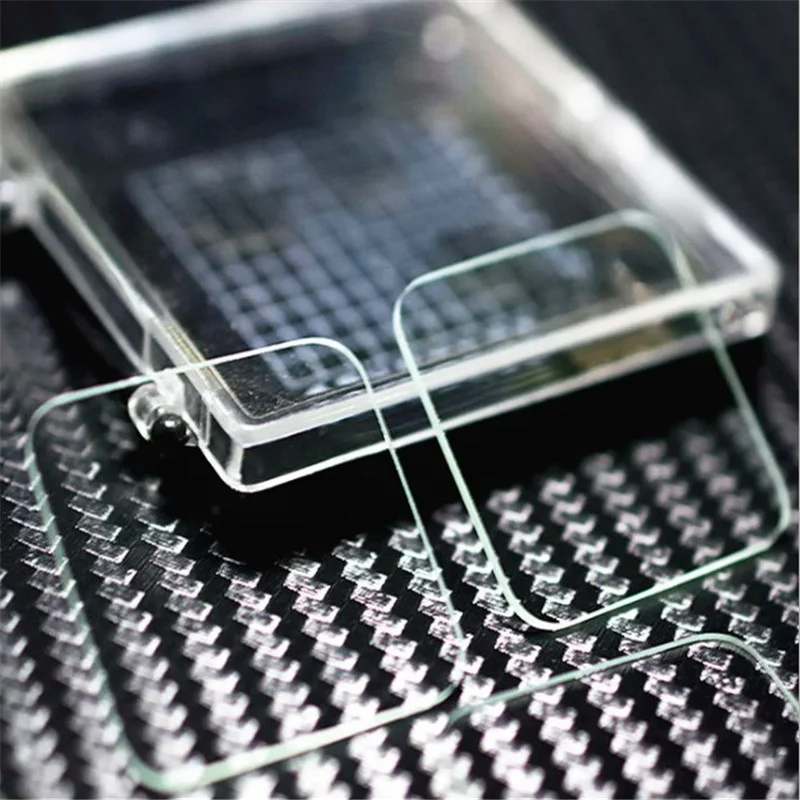

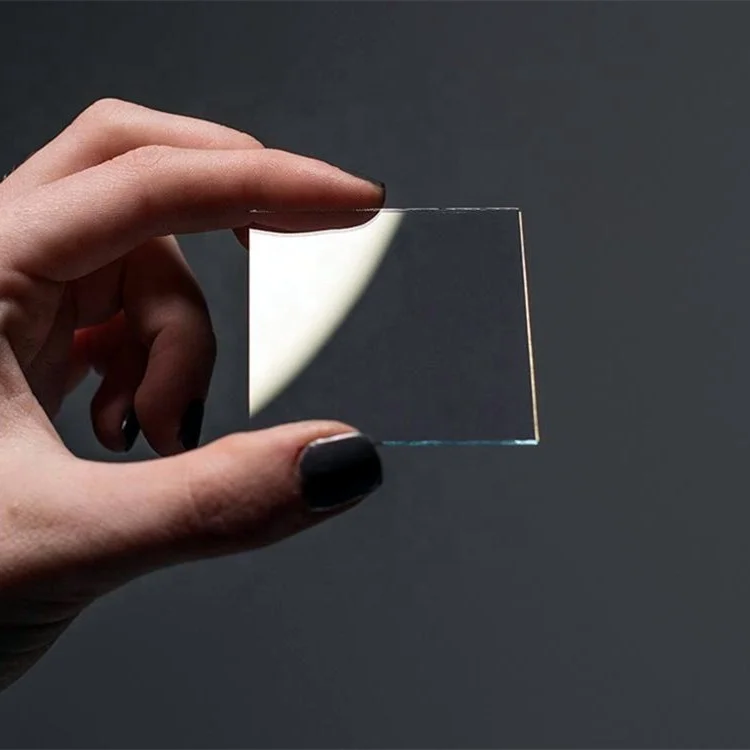

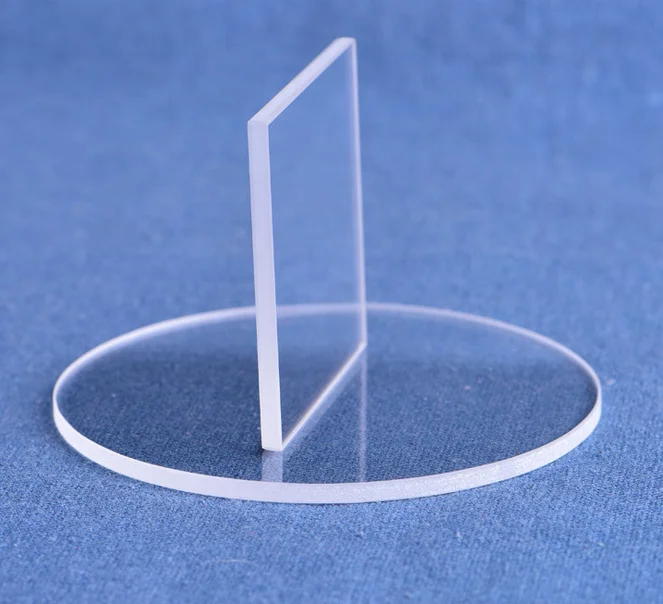

Detailed Images

Different Glass Wafer

Optical lens

Spotlight glass disc

Optical filter

Cover glass

Our Company

Packing & Delivery

Contact us

Tel:86+13414986564

Skype : yinhuanspring

Sales manager:Spring Lin

.

Похожие товары

Смотровое стекло SGN6S 014-0181

US $10.00-$12.00

Диски из боросиликатного стекла

US $1.35-$5.00

Форма для презервативов из боросиликатного стекла

US $0.30-$1.00