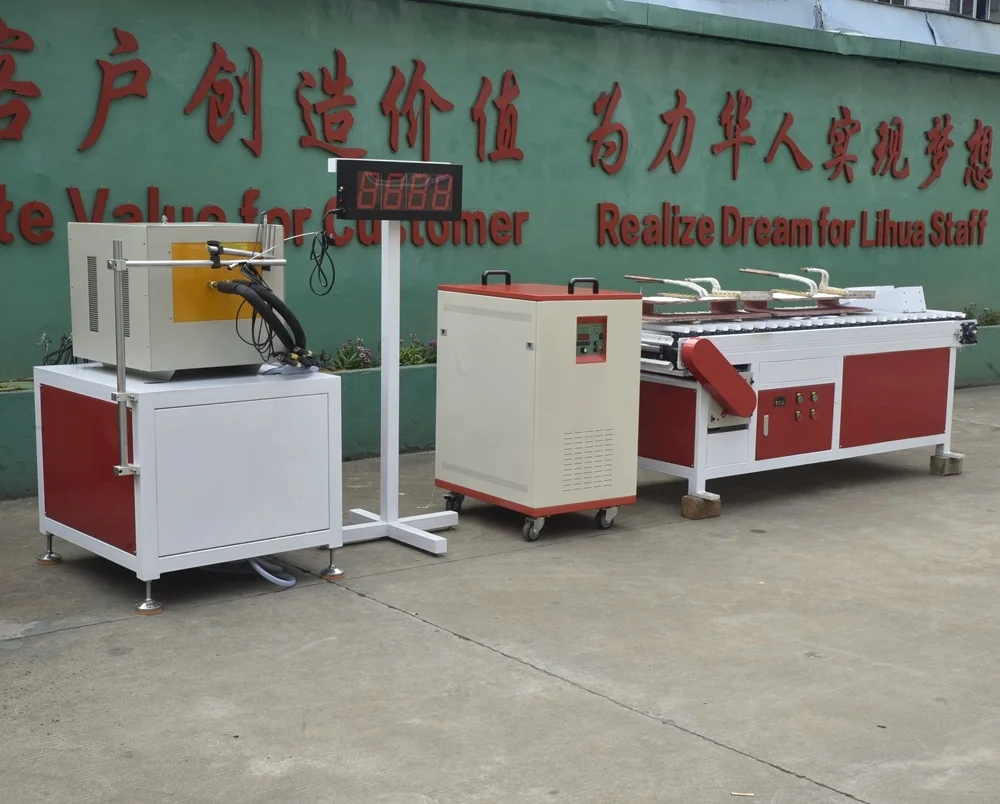

Металлокованый нагревательный станок 45 кВт средней частоты индукционный нагреватель кованый

- Категория: Кузнечное оборудование для металла >>>

- Поставщик: Guangdong,Lihua,Induction,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.70 $* | 0.44 $* |

| Aug-16-2025 | 0.50 $* | 0.82 $* |

| Jul-16-2025 | 0.15 $* | 0.64 $* |

| Jun-16-2025 | 0.24 $* | 0.43 $* |

| May-16-2025 | 0.53 $* | 0.45 $* |

| Apr-16-2025 | 0.84 $* | 0.45 $* |

| Mar-16-2025 | 0.5 $* | 0.19 $* |

| Feb-16-2025 | 0.44 $* | 0.71 $* |

| Jan-16-2025 | 0.17 $* | 0.15 $* |

Характеристики

Product Description

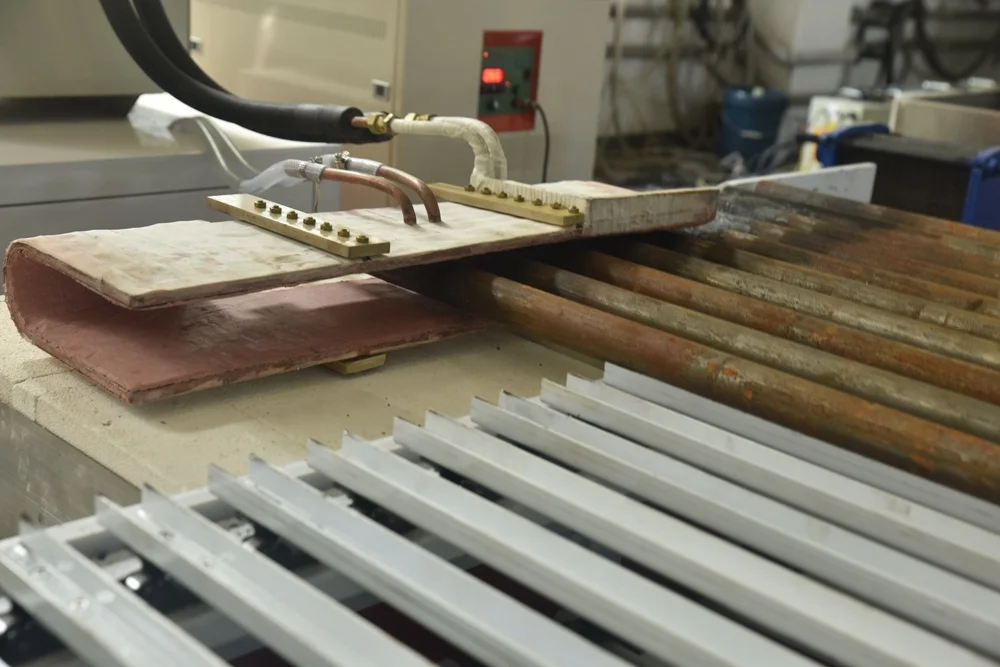

Induction forging: refers to the use of an induction heater to pre-heat metals prior to deformation using a press or hammer. Typically metals are heated to between 1,100 °C (2,010 °F) and 1,200 °C (2,190 °F) to increase their malleability and aid flow in the forging die.

Process: Induction heating is a non-contact process which uses the principle of electromagnetic induction to produce heat in a workpiece. By placing a conductive material into a strong alternating magnetic field, electrical current is made to flow in the material, thereby causing Joule heating. In magnetic materials, further heat is generated below the Curie point due to hysteresis losses. The generated current flows predominantly in the surface layer, the depth of this layer being dictated by the frequency of the alternating field and the permeability of the material.

Advantages: ■ Process controllability ■ Energy efficiency ■ Rapid temperature rise ■ Process consistency

Application: It is suitable for diathermy of copper rods, iron rods and aluminum rods of different shapes. The workpiece can be heated as a whole or locally.

Advantages: ■ Process controllability ■ Energy efficiency ■ Rapid temperature rise ■ Process consistency

Application: It is suitable for diathermy of copper rods, iron rods and aluminum rods of different shapes. The workpiece can be heated as a whole or locally.

Product Paramenters

Model | Output power | Frequency | Size of the heated workpiece Heat steel and stainless steel to 1100℃; brass to 700℃ |

LHDZ-25 | 25KW | 1-20Khz | Used for Ø12-30mm bar |

LHDZ-35 | 35KW | ||

LHDZ-45 | 45KW | ||

LHDZ-70 | 70KW | ||

LHDZ-90 | 90KW | ||

LHDZ-110 | 110KW | ||

LHDZ-160 | 160KW | Used for Ø15-90mm bar | |

LHDZ-200 | 200KW | ||

LHDZ-250 | 250KW | ||

LHDZ-300 | 300KW | ||

LHDZ-400 | 400KW |

Recommend Products

Production Process

Company Profile

LIHUA company has been committed to the development, production as well as the sales of induction heating equipments since 2005. Our own garden-style factory covers an area of 10,000 square meters. The company has undergone 8 times production process optimizations and 5 times production equipment updates. LIHUA obtained the honor of national high-tech enterprise and more than 60 patent certificates. We provide efficient and diversified inducting heating solutions tailored for the needs of customers. In response to different voltage levels in different countries, induction heating equipment with corresponding input voltage has been developed. The products are equipped with English manuals. Our technicians will serve you online 24 hours before and after sale. You can benefit from our experience in the field of induction heating. Your success is LIHUA's goal!

Customer Photos

FAQ

Q: Why use induction heating?

A: ★ Improved process efficiency ★ Localized, constant and precise heating ★ Temperature control ★ Energy saving ★ Possibility of integration into production lines ★ Best quality and yield/performance ★ Pollution free, fast and secure technology ★ Improved working environment

Q: Why choose LIHUA induction forging furnace?

A: 1. Small in size and movable, it is convenient to use with any forging and rolling equipment and manipulators.

A: ★ Improved process efficiency ★ Localized, constant and precise heating ★ Temperature control ★ Energy saving ★ Possibility of integration into production lines ★ Best quality and yield/performance ★ Pollution free, fast and secure technology ★ Improved working environment

Q: Why choose LIHUA induction forging furnace?

A: 1. Small in size and movable, it is convenient to use with any forging and rolling equipment and manipulators.

2. It can be heated to the required temperature in a very short time, greatly reducing metal oxidation, saving materials and improving forging quality.

3. It can work 24 hours a day, saving electricity, environmental protection and reducing costs.

4. The furnace body can be easily replaced to meet the different requirements of overall heating or end heating.

5. According to different application requirements, it can also be equipped with infrared thermometers, temperature controllers and automatic feeding devices.