QGN машина для дробеструйной обработки стальных труб оборудование пескоструйной внутренних

- Категория: >>>

- Поставщик: Shandong,Kaitai,Shot,Blasting,Machinery,Share,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.13 $* | 0.0 $* |

| Aug-17-2025 | 0.57 $* | 0.15 $* |

| Jul-17-2025 | 0.93 $* | 0.93 $* |

| Jun-17-2025 | 0.90 $* | 0.34 $* |

| May-17-2025 | 0.70 $* | 0.38 $* |

| Apr-17-2025 | 0.36 $* | 0.31 $* |

| Mar-17-2025 | 0.1 $* | 0.26 $* |

| Feb-17-2025 | 0.48 $* | 0.34 $* |

| Jan-17-2025 | 0.17 $* | 0.45 $* |

Характеристики

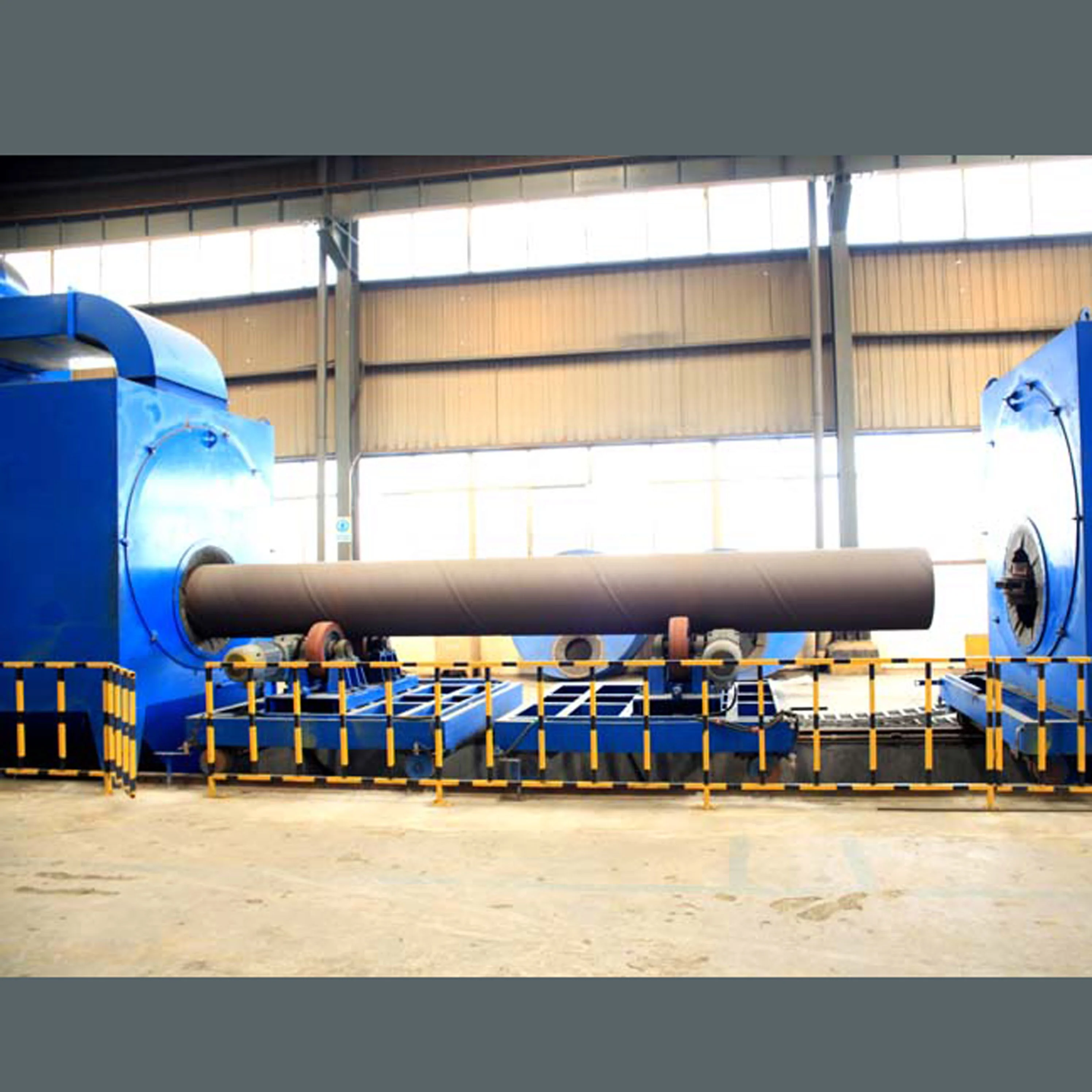

QGN Steel pipe inner wall special sandblasting equipment shot blasting machine

Regarding steel pipe with diameter of 16~600mm, we adopts V type conveyor which have an angle with steel pipe center line, steel pipe can rotation while going forward.

Regarding steel pipe with diameter of 159~2800mm, we adopts roller transmission, angle between roller is adjustable, running speed and rotation speed can be adjustable with large diameter, blasting wheel adopts bottom blasting distribution, cleaning efficiency is high, result is good.

Shots material circulation purification system takes overflow induction controllable full multi-stage curtain winnowing splitter and special polyester core elevator conveyor, achieves shot material sorting and recycling.

Blasting room adopts multi-layer seal curtain which is suitable for different diameters, shot blasting, dust removal system uses impulse reversal blowing filter cartridge dust collector, dust removal is good, life is long.

This equipment can be used for water, gas, mining, oil and pipe coating pretreatment, the seabed or desert gas such as duct blaster, it can improve the appearance quality of the product components and the state of the surface craft.

Model | Cleaning size | Cleaning speed | Purpose |

QGW100 | 50-300 | 2-10 |

Outer wall shot blasting machine |

QGW720 | 159-720 | 2-6 | |

QGW1200 | 219-1016 | 1-6 | |

QGW1500 | 325-1600 | 1-6 | |

QGW2800 | 1016-2800 | 1-2 |

Equipment main structure and characteristics of steel pipe shot blasting equipment :

QG Series Steel Pipe shot blasting machine is consisted of shot blasting chamber, blasting wheel assembly, shot material cycle purify system, roller transmission system, dust removing system, electric control system and so on.

1.Shot blasting chamber

Shot blasting chamber is welded by Q235 steel plate and steel frame. Meanwhile, shot blasting chamber equip testing door, which is the seal space to clean the workpiece. Inside of shot blasting chamber is protected by cast iron protective plate (material ZCr5,thickness 10mm), meanwhile, it is impacted by protective cap.

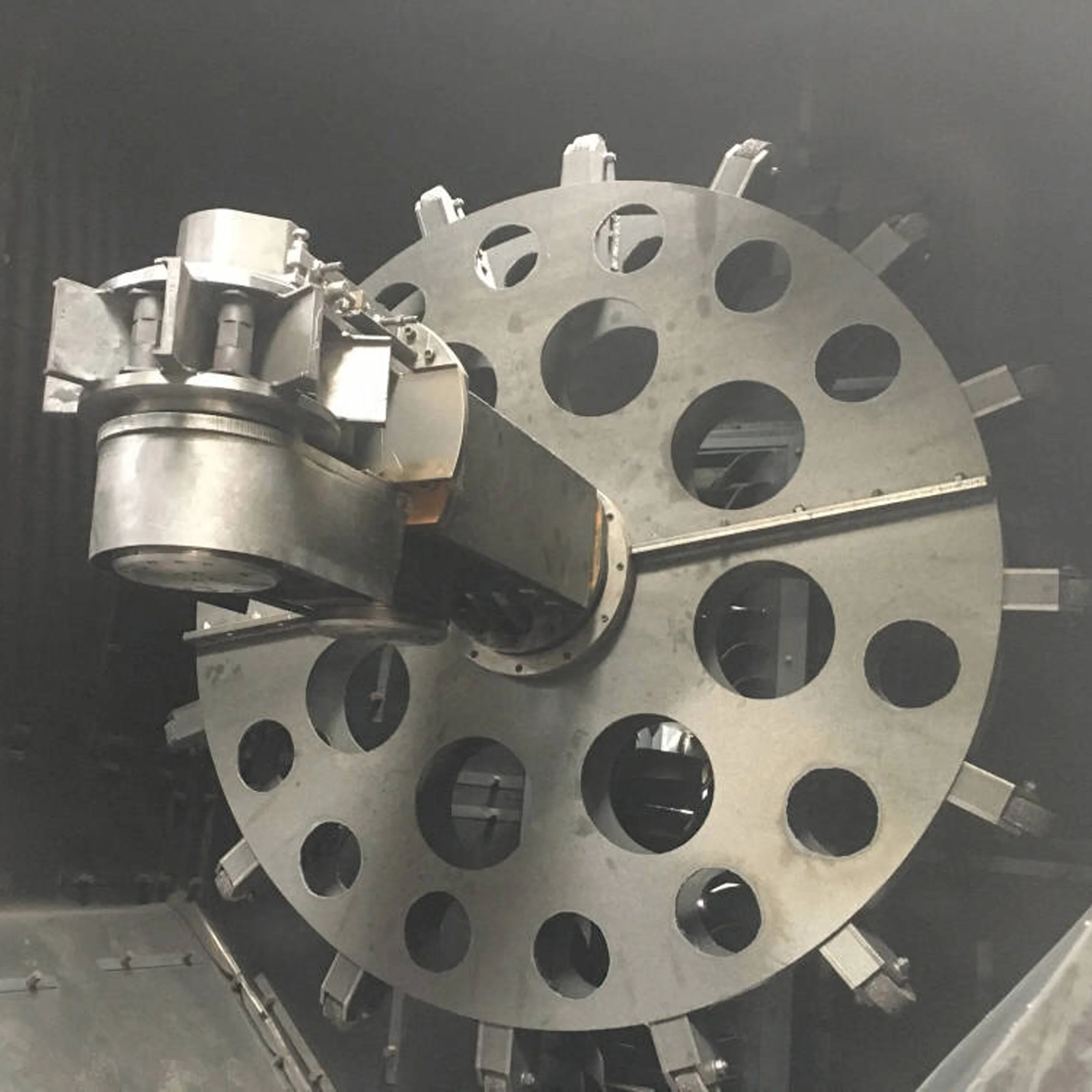

2.Blasting wheel assembly

Two sides of top shot blasting machine equip two sets blasting wheel assembly. The location of blasting wheel is calculated by computer three-dimensional dynamic simulation. The location and angel are calculated by computer to assure the workpieces completely cleaning.

3.Shot material cycle purify system

It is consisted of screw conveyor, bucket elevator, shot and grit separator, supplying shot sluice valve ,slipping shot pipe and so on.

4.Roller transmission system

Transmission roller consists of charging roller and discharging roller.

5.Dust Collector

It consists of dust collector body, blower, settling tank and pipeline.This equipment takes two grade dust removal, the dust goes through settling tank first, the large grain will fall down through inertia, then large particles will come out by filter cylinder type.

Quality and After-sale Assurance

1. Supplier promise the name, model, specification and quantity comply with technical protocol, assuring the machine is new equipment with qualified material manufactured through perfect technology. There are no defects in design, material and technologies, which is suitable for propose of demander, and meets the standard of national industry. The quality is stable and reliable.

2. Equipment warranty period is 12 months after the final acceptance( except force majeure, inappropriate operation and the quick-wear parts wears).

3. The equipment will pass the installment and test before delivery, after the quality is qualified, we will disassembly the equipment, coating and deliver.

1.We can design and produce for our customer according to the cleaning requirements of workpiece.

2.Our machine advantages:advanced design, reasonable structure ,low-power consumption and perfect efficiency.

3.Our main market : worldwide,South-east,Middle-east ,Europe and South America.

4.Our shot blasting spare parts are high quality.Blaster can reach uttermost long-life , environmental protection, high efficiency in service. The material, durability:

name | Material | Life |

blades | High chromium Precision casting | ≥800h |

control cage,distributor | High chromium Precision casting | ≥1000h |

protection plate | High chromium | ≥1500h |

side plate | High chromium | ≥2500h |

impeller | 40Crquenching | ≥2500h |

If you want to customize shot blasting machine,could you tell me the answers as follow?

1) What kind of workpiece will you clean?

2) The size of it, length, width and height of maximum workpiece? Length, width and height of minimum workpiece?

3) How heavy is each workpiece? Especially the weight of maximum workpiece?

4) How many tons will you clean for each month or each day?

5) Do you have any special request for electrical components brand?

After get confirmation from you, our engineer will make the detailed technical parameters for your reference.

.How to visit your factory?

Our company is not far away from Jinan city Shandong province,we can pick you up here.