Машина для изготовления нетканых тканей/машины

- Категория: Нетканые машины >>>

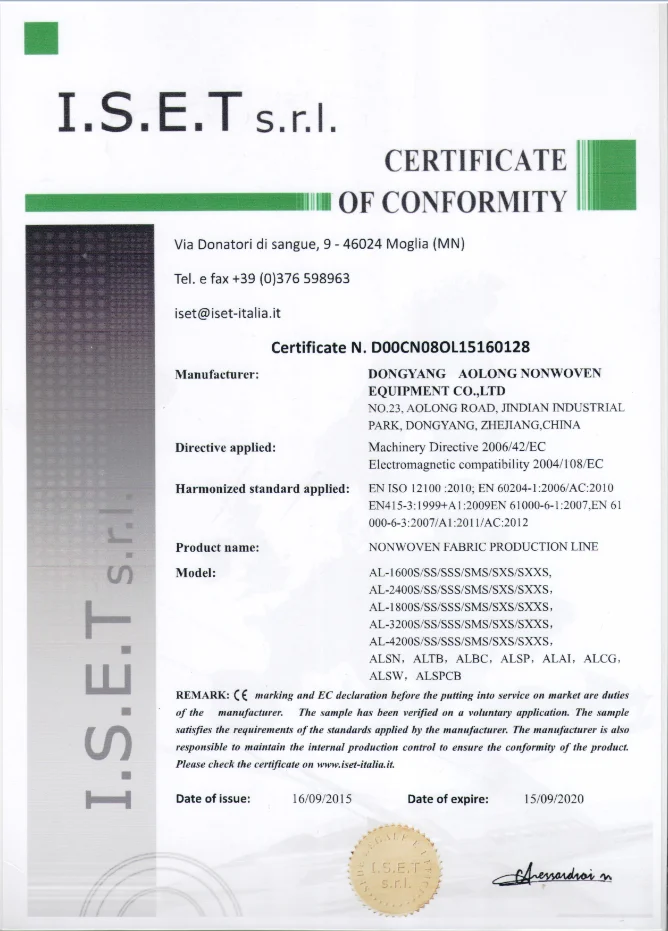

- Поставщик: Dongyang,Aolong,Nonwoven,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 297500.35 $* | 312375.35 $* |

| Aug-16-2025 | 295000.17 $* | 309750.65 $* |

| Jul-16-2025 | 247500.48 $* | 259875.69 $* |

| Jun-16-2025 | 290000.6 $* | 304500.12 $* |

| May-16-2025 | 252500.99 $* | 265125.3 $* |

| Apr-16-2025 | 285000.77 $* | 299250.52 $* |

| Mar-16-2025 | 282500.59 $* | 296625.6 $* |

| Feb-16-2025 | 280000.58 $* | 294000.38 $* |

| Jan-16-2025 | 277500.76 $* | 291375.54 $* |

Характеристики

nonwoven fabric making machine

nonwoven fabric machine

nonwovne fabric machines for shoping bags

SINGLE BEAM STYLE PP NON WOVEN FABRIC MACHINE

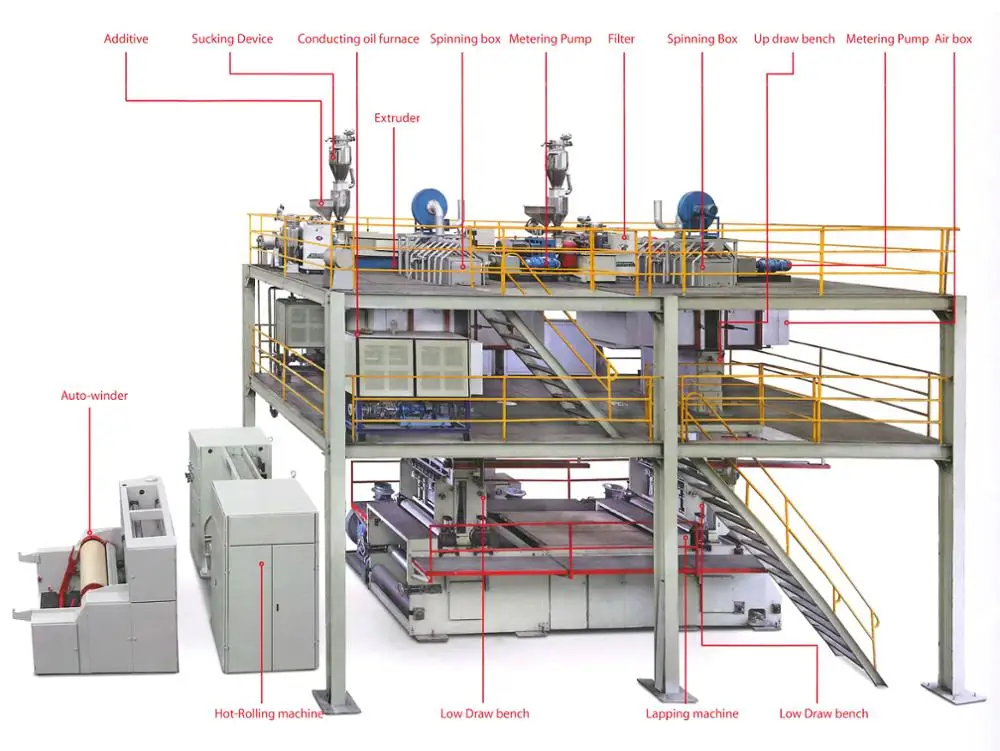

The polypropylene (PP) spunbond non-woven fabric, SMS composite nonwoven equipment was constantly upgrading after years of practice and production operations, which makes the design and operation more reasonable. At the same time, digestion and absorption of foreign advanced technology similar equipments, complete specifications, superior performance, net uniform, beautiful color, good quality, and can also add renewable raw materials and filler materials to reduce product costs.

S, SS, SMS customerized PP nonwoven fabric production line available.

Working width: 1600mm, 2400mm, 3200mm

Features Specifications:

1. Width: 1.6m, 2.4m, 3.2m

2. Max winding diameter: 1000mm

3. Productivity: 40g/square meter, 3t---10t/24 hours.

4. Monofilament Fiber number; 2.5 Den

5. Main material: PP chips

6. Grammage: 15-250GSM

7. Mechanical speed: 10-120m/min.

8. Electricity consumption: 800-1400kwh/t

9. Material wastage consumption rate: 0.5%

10. Product quality standard: National spunbond nonwoven standard

Type of Machine

Type: S1.6, S2.4, S3.2, SS1.6, SS2.4, SS3.2, SMS, 1.6, SMS2.4

(S stands for spunbonded, M stands for meltblown)

Main Features

1) It's a professional non-woven fabric production line. Our company adopts overseas advanced technology and domestic production experience, developed this line. The line's advantage is lower investment, compact construction, smaller working area, easy production technology and operation, less labors and widely compatibility and so on.

This line produces polypropylene(PP) non-woven fabric, fabric is forming by negative pressure wind to make the PP spun-bonded non-woven fabric more even, great tensity, better ventilation and better soft feelings and so on. It has been in wide application for medical clothes, package and architecture and so on.2) Under the conditions of technology requirement and safe requirement, reduce some unnecessary auxiliary facilities brings the lower investment, and the lower operation cost.

3) It's easy and reliable for technics adjustment, thanks to the computer control system to make the technics adjustment more easier and reliable, and the line can be suitable for different raw material to gain more widely usage.

4) Simple requirement for the work floor, it can greatly reduce the real estate investment and enlarge the utilization of the workshop and the steel platform.

5) Using more specialized processing equipment, improve the machine's accuracy and performance, reduce manufacturing costs, and better quality for the final product.

Spinning Box

Orifice number: 11091

0.45mm

Diameter of spinneret hole: 0.45mm

Heat Pressure: heat-transfer oil circular heating

Liquid pp raw mater passed spinneret's

Holes become filament;

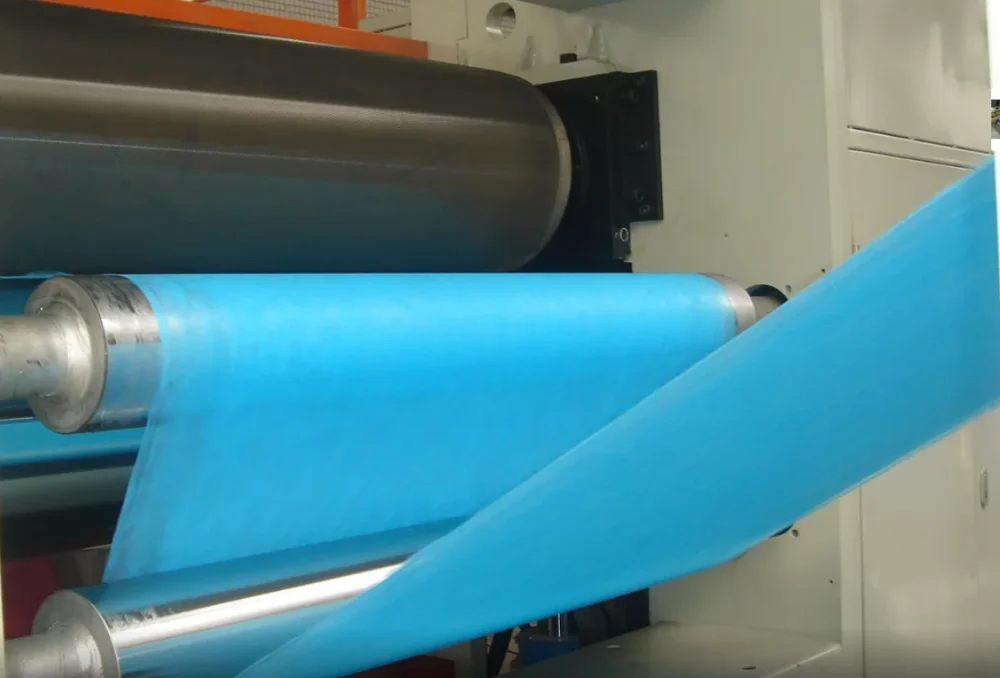

Calender

speed: 10-150m/min

Roller width: 2000mm

Calendar material : 42CrMo

Individual motor control

By the roller pressure make embossing pass to next machine

Main extruder

Diameter:130

Speed: 10-75r/min

Capacity:300kg/h

Extruder is used to melt and extruder PP Chips, master batches and some additives such as antioxidant, anti-pilling agent and flame retardant agent. And, the extruder machine consists of chip inlet, automatic temperature control, cooling device and alarming device.

Main drive employs A.C. frequency control. The temperature control for each zone adopts closed-loop system with WEST temperature meter, solid relay and pt100 platinum resistance.

Pp.

Slitting machine

Speed : 10-400m/min

Winding diameter: 1200mm

Reason to customers require to slitting fabric

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

| \t | |

| \t | \t |

| \t | \t |

| \t | \t |

non woven bag making machine high quality

91.8% Response Rate

PET or PP thermal bonding oven machine polyester wadding mattress fabric making nonwoven machine

91.8% Response Rate

PET needle punching carpet making machine low price

91.8% Response Rate