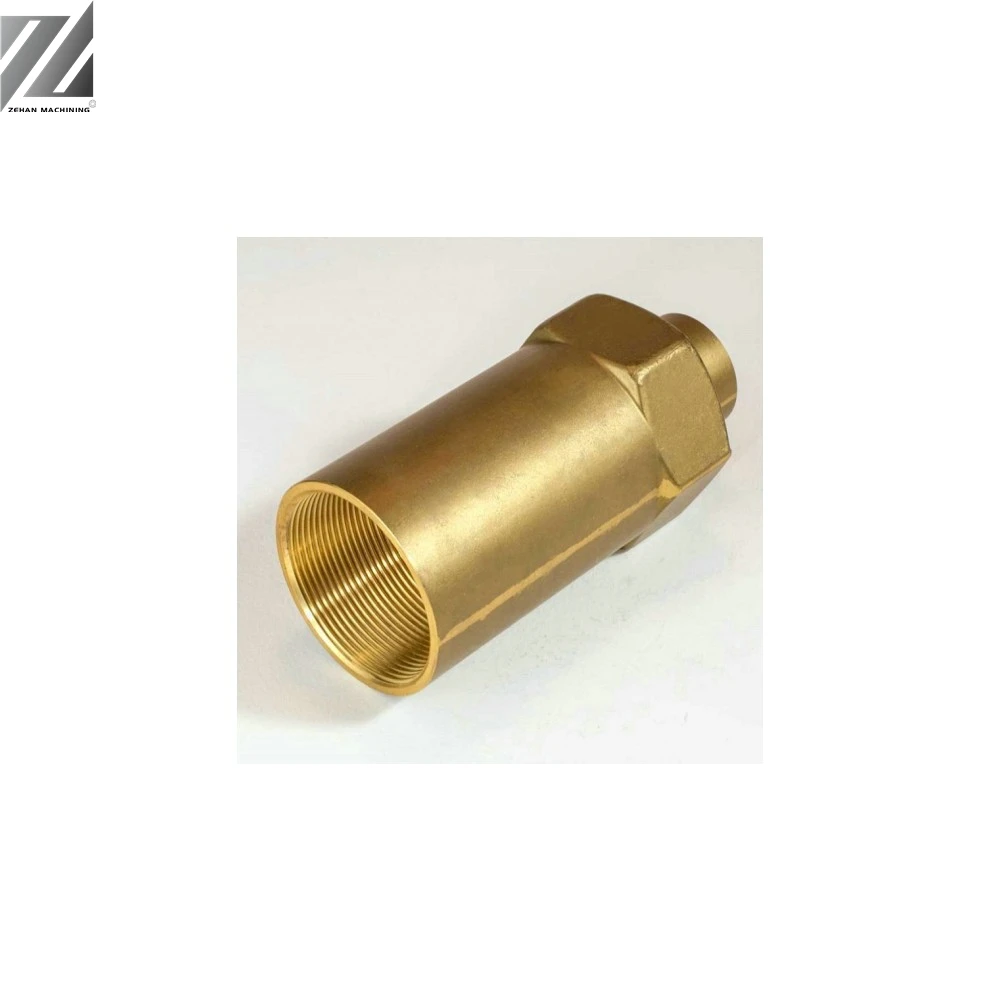

Пользовательские латунные Горячие кованые детали с высокой производительностью для фитинга

- Категория: Ковка >>>

- Поставщик: Qingdao,Zehan,Machinery,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.48 $* | 0.75 $* |

| Aug-16-2025 | 0.54 $* | 0.61 $* |

| Jul-16-2025 | 0.83 $* | 0.4 $* |

| Jun-16-2025 | 0.75 $* | 0.57 $* |

| May-16-2025 | 0.15 $* | 0.19 $* |

| Apr-16-2025 | 0.50 $* | 0.83 $* |

| Mar-16-2025 | 0.18 $* | 0.94 $* |

| Feb-16-2025 | 0.76 $* | 0.69 $* |

| Jan-16-2025 | 0.74 $* | 0.56 $* |

Характеристики

Custom Brass Hot Forging Parts with High Performance for Pipe Fitting

Custom Brass Hot Forging Parts with High Performance for Pipe Fitting | |

Quality Assurance | ISO9001:2015 Certified |

Machining Equipment | Machining Center / CNC Lathes / Grinding Machines / Milling Machines / Lathes / Stamping Machines/ Full Automatic Lathe /etc. |

Surface Treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting |

Inspection | Projector etc. |

File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

Item Name | Brass Forging Parts |

Quality Assurance | ISO9001:2015 Certified |

Machining Equipment | Machining Center / CNC Lathes / Grinding Machines / Milling Machines / Lathes / Stamping Machines/ Full Automatic Lathe /etc. |

Materials | Aluminum Alloy: |

5052 /6061/ 6063 / 2017 / 7075 / etc. | |

Brass Alloy: | |

3600/ 3602 / 2604 / H59 / H62 / etc. | |

Stainless Steel Alloy: | |

303 / 304 / 316 / 412 / etc. | |

Steel Alloy: | |

Carbon Steel / Die Steel / etc. | |

Other Special Materials: | |

Lucite / Nylon / Bakelite / etc. | |

We handle many other type of materials. Please contact us if your required material is not listed above. | |

Surface Treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting |

Inspection | Projector etc. |

File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

What Is Brass Hot Forging?

According to the forging temperature, forging can be classified into hot forging, cold forging and warm forging. Most mental components intended to be forged are performed under hot forging.

Brass hot forging can be defined as “ a shaping process in which a brass bar, is worked to a predetermined shape by one or more processes such as hammering, upsetting, pressing and so forth where the bar is heated up to about 75% of its melting temperature”. The process begins with a cast ingot, which is heated to its plastic deformation temperature, then forged between dies to the desired shapes and size.

The Advantages & Benefits of Brass Hot Forging

The brass hot forgings are quality parts, comparing favorably in material integrity, dimensional tolerance and surface finishing with products made using other major metalworking processes. As a result of deformation, hot brass forging grants superior density and freedom from flaws. Forming under heat and pressure in precise closed dies produces dimensional accuracy, always repeatable part to part and lot to lot.

The specific advantages of brass hot forging parts are as follows:

1. Higher Strength

As the forging temperature of the brass bar is prior to the melting temperature, the flow stress and energy required to form the material are decreased and the strain rate or production rate can also be increased. Therefore, hot forging results in metal that is stronger than cast or machined metal parts.

2. Lower Overall Cost

Mass production of brass forged parts lends itself to maximum savings. However, smaller quantities of copper alloy forgings can also prove economical when specific design problems must be overcome. These problems include leak integrity, close tolerances, high strength with low weight, and non-symmetrical shape. Besides, hot forging don’t have to reach the molten temperatures.

3. Leak Resistance

The dense non-porous forged metal permits the designer to specify thinner sections without the risk of leaks due to flaws and voids. Often the thinner forged parts result in lighter weight and lower part cost compared to other forming processes.

4. Close Tolerances

Overall part dimensions are held closer than in sand casting. Dimensions show minimum variation from part to part and permit automatic chucking and handling in subsequent operations. The precise designs on the die surface can produce sharp impressions on the forging surface, which is not economical with other forming processes.

Brass Hot Forgings’ Application

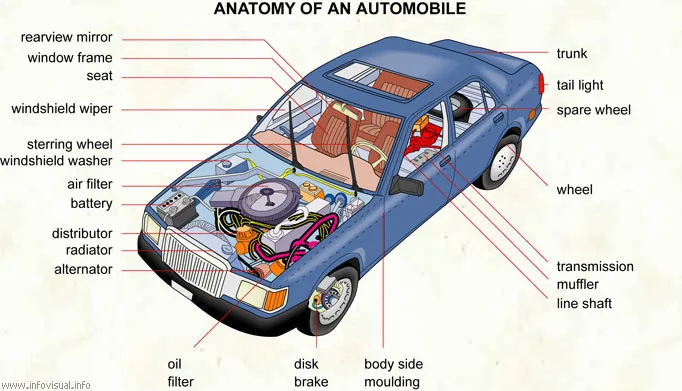

Automobile

1. Battery clamp

2. Valve for brake system

3. Anti-vibration element steering colom

Aerospace

1. Injector plates

2. Thrust cones

3. Engine pick up blocks

4. Shafts

5. Spinners

Sanitary

1. Mounting body for water connector

2. Body for mixing valve cold-warm water

3. Body water faucet

Valve technology

1. Body for breathing air valve

2. Valve cover

3. Valve safety group

Power management

1. Mounting bracket

2. Switching component

3. Safety switch

Heating & Cooling (HVAC)

1. Adaptor heating system

2. Body mixing valve heat pump

3. Cooling valve body

Products Gallery

What’ s the Differences Between Hot Forging and Cold Forging?

The cold forging manufacturing process is performed at room temperature. While the hot forging manufacturing process is performed at extreme high temperature (up to 1150°C for steel, 360 to 520°C for al-alloys, 700 to 800°C for cu-alloys).

The cold forging manufacturing process increases the strength of a metal through strain hardening at a room temperature. On the contrary the hot forging manufacturing process keeps materials from strain hardening at high temperature, which results in optimum yield strength, low hardness and high ductility.

Why Choose Us?

Qingdao Zehan Machinery Manufacturing Co. Ltd has focused on CNC machining, stamping, casting, forging and 3D printing for over 20 years. Based on our extensive expertise and impressive stock of presses for brass forging, we are able to supply the right press and full forging line to any brass forger, no matter how hard the task is.

Zehan is committed to providing customized machining services for brass, copper, steel, aluminum, stainless steel, plastic, nylon, POM and other materials over 20 years. We can also provide more accurate OEM and ODM service according to customer's design requirement. At present, Zehan has served more than 70 internationally influential customers represented by the HUNTER Engineering Company in the United States, and won the only China Quality Supplier Award of Hunter Engineering Company without complaint on quality and delivery among 300+ global suppliers for 3 consecutive years. Our market covers the United States, France, Belgium, Germany, Poland, the United Arab Emirates, Korea and other 26 countries. We have a complete production and supply service system for 3D printing prototype, CNC Machining, CNC turning, CNC milling, hot forging, sheet metal stamping, precision casting, welding and surface treatments for finished parts.

FAQ

1. ZH can design the drawings for me?

Sorry, we can't provide the design service. Please send your 2D,3D,PDF or CAD drawings to us, we will provide the manufacturing design review after receiving your order.

2. How can I know that my design will be secret?

We will sign and comply with any non-disclosure or confidentiality agreement. And we had the strict policy in our factory, anyone can't take the photos for customer's products without permit.

3. How does ZH compare to the price of other suppliers?

Though the compare is difficult directly, but ZH compare with China supplier, we don't compare the price, but provide the higher-level quality, rapid response, on time delivery and standard service.

4. What tolerances can ZH achieve?

There is not a set of tolerances fit all of the process and materials. In different situations, the final to tolerances of parts will be depend on the many factor, including but not limited to part dimensions, design geometry, quantity, type and size materials

surface treatment and manufacturing process. ZH have a whole set of part inspection standards, all of the fabrication and technical specifications need clear define in the part inspection standards.

5. How does ZH ensure the quality of my parts?

Once your order is confirmed, we will execute the whole fabricate design (DFM) review, so that our engineers think that maybe affect any quality problems of your parts. And we will use a set of test equipment to check and confirm the all materials.

Also, we promise 100 percent inspection before shipping.

We are able to real-time sharing the inspection data with you, so we also can work together to solve any quality problems that you may encounter during the production process.

6. What type of surface treatment does ZH provide?

We provide all kinds of surface treatment service, like zinc plating, anodizing, chrome plating, nickel plating, blacking oxide coating, electrophoretic paint, powder coating etc.

7. What if I am not completely satisfied with the parts I received?

According to the customer's drawings, materials and technics, we produce the parts with strict inspection to meet customers’ requests, so our company does not take any responsibility. But if the problem is caused by our processing negligence, we will 100% take responsibility and negotiate settlement program with you.

8. How do I pay for ZH?

ZH accept the payment method as following:

1.T/T wire transfer

2.ZH also can accept the western union

3.ZH can send the PayPal invoice to you and you can using the PayPal account or credit card to payment