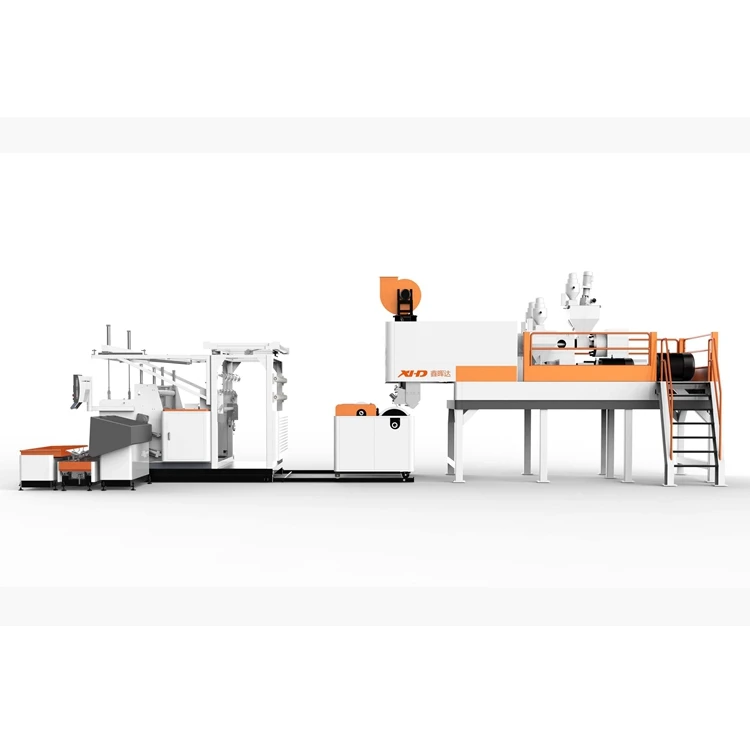

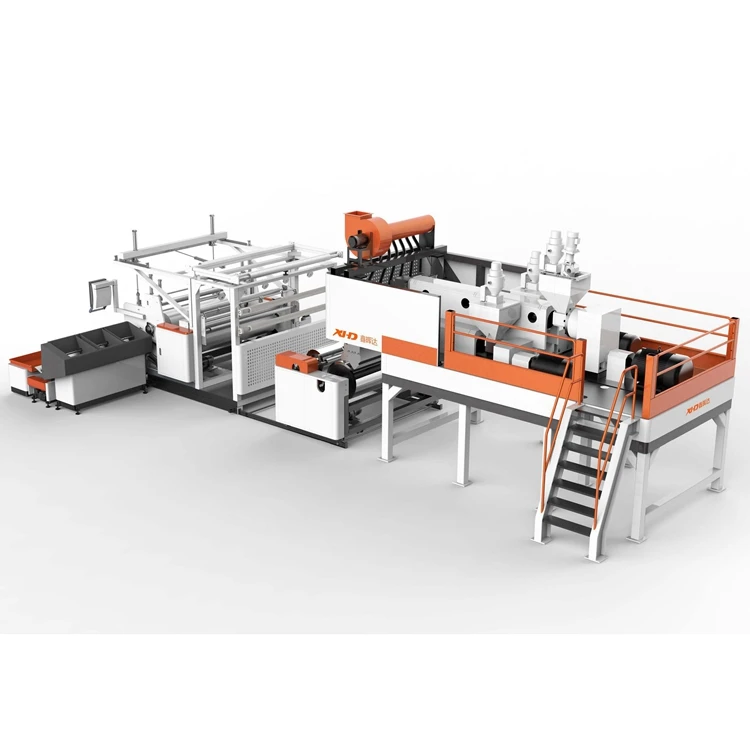

Оборудование для литья пленки

- Категория: Blown Film Production Line >>>

- Поставщик: Guangdong,Xinhuida,Machinery,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 104720.98 $* | 109956.74 $* |

| Aug-17-2025 | 103840.55 $* | 109032.56 $* |

| Jul-17-2025 | 87120.46 $* | 91476.68 $* |

| Jun-17-2025 | 102080.48 $* | 107184.35 $* |

| May-17-2025 | 88880.89 $* | 93324.59 $* |

| Apr-17-2025 | 100320.60 $* | 105336.74 $* |

| Mar-17-2025 | 99440.55 $* | 104412.67 $* |

| Feb-17-2025 | 98560.58 $* | 103488.42 $* |

| Jan-17-2025 | 97680.60 $* | 102564.61 $* |

Характеристики

pe stretch film machinery cast film machine

Item | Specs |

Voltage/Frequency/Phase | 220 V/440 V/415 V/380 V, 50 HZ/60 HZ, 3 Phases. |

Total Installation Power | 150 KW |

Consumption Power | Around 90 KW |

Main Raw Material | LLDPE, metallocene |

Thickness of Film | 10-50 μm |

Width of the Useful Film | 1500 mm/3 rolls×500 mm/3 rolls*450 mm/5 rolls*300 mm |

Film Layer Structure | ABC or ACBCA |

Designed Linear Speed | 200 M/min |

Extrusion capacity | 280 Kg/h |

Dimensions (L×W×H) | 12.5×5.5×3.8 M |

Gross Weight | 15000 Kg (for reference only) |

Highlights on performance

1. High speed design: up to 200 M/min (the fastest designed speed and real running speed among similar machines).

2. High production capacity: 200~250 KGS/H (the biggest production capacity at lower microns among similar machines).

3. Quality stretch film which can compare with the film produced by European machines.

4. Suitable for producing both machine use stretch film rolls and hand use stretch film rolls.

5. Excellent production capacity and power consumption ratio.

6. One man is enough to manipulate the whole machine!

Highlights on configuration

1. Martin type coupling is used for connecting the main motor and the gear box (much better than the pulley and belt connection).

2. Alloy screws and barrels with good nitrogen treatment.

3. Automatic screen changers powered by hydraulic station.

4. Top quality JC-TIMES T-die (Most famous Chinese brand and world-famous brand, optional).

5. Powerful and stable electrostatic film edges and trim treatment.

6. Big and quality cooling rollers from professional suppliers.

7. Film expanding rollers and oscillation system are installed to erase possible wrinkles before slitting.

8. Big diameter winding roller with frosted surface.

9. Patented paper cores unloading and loading system.

10. No need to do the air shaft inflation, deflation and paste the BOPP tape on the cores.

Except for this model, we also have other stretch film (production line) with different winding design and production capacity (100~460 KGS/H) for customer's option.

The whole set of stretch film machine (production line) are to be disassembled into several parts and packed by stretch film. They will be loaded into 2 pieces of 40 HQ containers and to be fastened inside the containers. We suggest that even though the parts are tightened, the customer still needs to buy the insurrance for the valuable stretch film machine. Below photos of loading are for customer's reference.

The lead time of the stretch film machine is arond 90~105 working days after receipt of the down payment.

Our stretch film machine equipment are sold to more than 60 countries. Please check the list as below. Some customers are more than customers and they are our friends so they will allow our potential customers to check the machine running in their factories.

A~G

Algeria, Argentina, Armenia, Azerbaijan, Bangladesh, Bahrain, Belarus, Bolivia, Brazil, Bulgaria, Cambodia, Cameroon, Colombia, Costa Rica, Czech, Ecuador, Egypt, Ethiopia, Fiji, Ghana, Greece, Guatemala.

H~R

Honduras, Hungary, India, Indonesia, Israel, Kazakhstan, Kenya, Korea (South), Kuwait, Latvia, Malaysia, Mexico, Morocco, New Zealand, Nigeria, Pakistan, Palestine, Panama, Peru, Philippines, Poland, Qatar, Romania, Russian Federation.

S~Z

El Salvador, Saudi Arabia, Serbia, Slovakia, South Africa, Spain, Sri Lanka, Syria, Thailand, Turkey, Ukraine, United Arab Emirates, United Kingdom, United States, Uzbekistan, Vietnam, Zimbabwe.

~ Registered capital of 1.5 Million USD.

~ 14 years’ focus on stretch film production equipment manufacturing.

~ 41 patents and passed the ISO9001: 2015 certification.

~ Our products has the certificate of CE Conformity and CE certificate.

~ A modern factory with an area close to 30000 Square meters.

~ A professional engineering team formed of technicians and engineers with years’ experience.

~ Manufactured 3000+ sets of stretch film production equipment in last 10 years.

~ Manufactured 50+ sets of 2000 mm stretch film production equipment in last 3 years.

~ Our machines are exported to 60+ overseas countries and cities, such as UK, Turkey, Russia, India, South Africa, K.S.A., UAE and Latin American countries.

~ More than 10 XINHUIDA offices or sales agents all over the world, such as Turkey, Thailand, South Korea, Peru, Ukraine, Vietnam and etc.