Машина для производства брикетов древесного угля/оборудование угля/машина обработки

- Категория: Briquette Machines >>>

- Поставщик: Gongyi,Yison,Honda,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.97 $* | 0.93 $* |

| Aug-16-2025 | 0.87 $* | 0.89 $* |

| Jul-16-2025 | 0.85 $* | 0.57 $* |

| Jun-16-2025 | 0.52 $* | 0.50 $* |

| May-16-2025 | 0.24 $* | 0.26 $* |

| Apr-16-2025 | 0.76 $* | 0.84 $* |

| Mar-16-2025 | 0.66 $* | 0.85 $* |

| Feb-16-2025 | 0.38 $* | 0.59 $* |

| Jan-16-2025 | 0.12 $* | 0.12 $* |

Характеристики

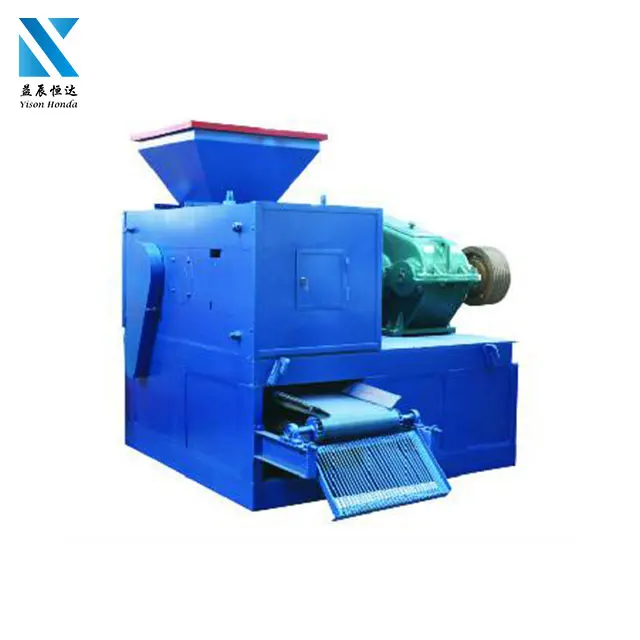

charcoal briquettes making machine/charcoal manufacturing equipment/carbon black processing machine

Briquette press machine, also named charcoal briquette machine, roller briquette press machine, ball press machine, charcoal making machine, etc. We can provide various kinds briquette press machine for making different kinds briquettes, such as pillow shape, ball shape, egg shape, oval shape, heart shape, bread shape, etc. The shape and size both can be customized according to customers special requirement. This machine can make 20-60 mm size briquettes, but usually 40mm, 45mm, 50mm are popular size. The raw materials can be charcoal powder, coal powder, mineral powder, fertilizer, salt, iron powder, AL powder, dry powder and other powders.

Model | Reducer | Roller Size | Main Shaft Speed | Power | Capacity |

TD290 | ZQ350 | 290*200mm | 12-14(r/min) | 5.5kw | 0.9-1t/h |

TD360 | ZQ350 | 360*250mm | 12-14(r/min) | 7.5kw | 1.5-2t/h |

TD400 | ZQ400 | 400*250mm | 12-14(r/min) | 7.5kw | 2.5-3.5t/h |

TD430 | ZQ400 | 430*250mm | 12-14(r/min) | 11kw | 3.5-4.5t/h |

TD500 | ZQ650 | 500*470mm | 10-12(r/min) | 37kw | 7.5*8.5t/h |

TD650 | ZQ850 | 650*470mm | 9-11(r/min) | 45kw | 9-10t/h |

TD750 | ZQ1000 | 750*570mm | 9-11(r/min) | 90kw | 13-14t/h |

TD850 | ZQ1250 | 850*570mm | 8-10(r/min) | 110kw | 15-17t/h |

Our advantages:

1.Professional briquetting press machine manufacturer

2.High briquetting ratio

3.High pressure

4.Durable & energy-saving

5.Offer installation guide

Notice:Some demands of coal charcoal briquette machine

(1) Inlet raw material need less than 3mm, as all know, the smaller the material, the better the briquettes.

(2) The material can't be mixed with metal material, or the mold is easily damaged.

(3) The raw material moisture need be controlled between 12%-15%.

(4) A certain proportation of liquid binder and charcoal powder, we will offer the proportation formula after we finished the order for free.

Rollers/Moulds and final products

>> 1.The finished products usually 20-60mm.

>> 2.The final products are smokeless, non-toxic, none peculiar and environmental protection.

>> 3.The shape can be Square, ball egg-shaped, round, oval, and column, strip-type, elliptic type,pillow type and other special shapes by customizing the matching molds.

Briquetting presss machine are widely used in refractory, powder plant, metallurgical, chemical engineering, energy, transportation, heating and other industries.

Pre-sale Service:

1. We will introduce the most suitable machine to clients.

2. We offer details explanation for customer in each step.

3. Design suitable product, offer the reasonable consultation.

After-sale Service:

1. We sent engineer install abroad & training worker. Necessary training about machine daily maintenance to local workers is provided also.

2. Offer free technical support any time. We have perfect after-sales service system and team with professional for whole using life.

3. Training how to instal the machine, training how to use the machine.

4. Welcome customer come to our factory.