Пластиковая дробилка серии Pc/машина для переработки

- Категория: Plastic Crushing Machines >>>

- Поставщик: Zhangjiagang,Friend,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.17 $* | 0.43 $* |

| Aug-19-2025 | 0.12 $* | 0.81 $* |

| Jul-19-2025 | 0.84 $* | 0.28 $* |

| Jun-19-2025 | 0.9 $* | 0.7 $* |

| May-19-2025 | 0.11 $* | 0.29 $* |

| Apr-19-2025 | 0.43 $* | 0.30 $* |

| Mar-19-2025 | 0.14 $* | 0.89 $* |

| Feb-19-2025 | 0.67 $* | 0.65 $* |

| Jan-19-2025 | 0.4 $* | 0.64 $* |

Характеристики

PC series plastic crusher /PET bottle recycling machine PC 300

Main features of the product:

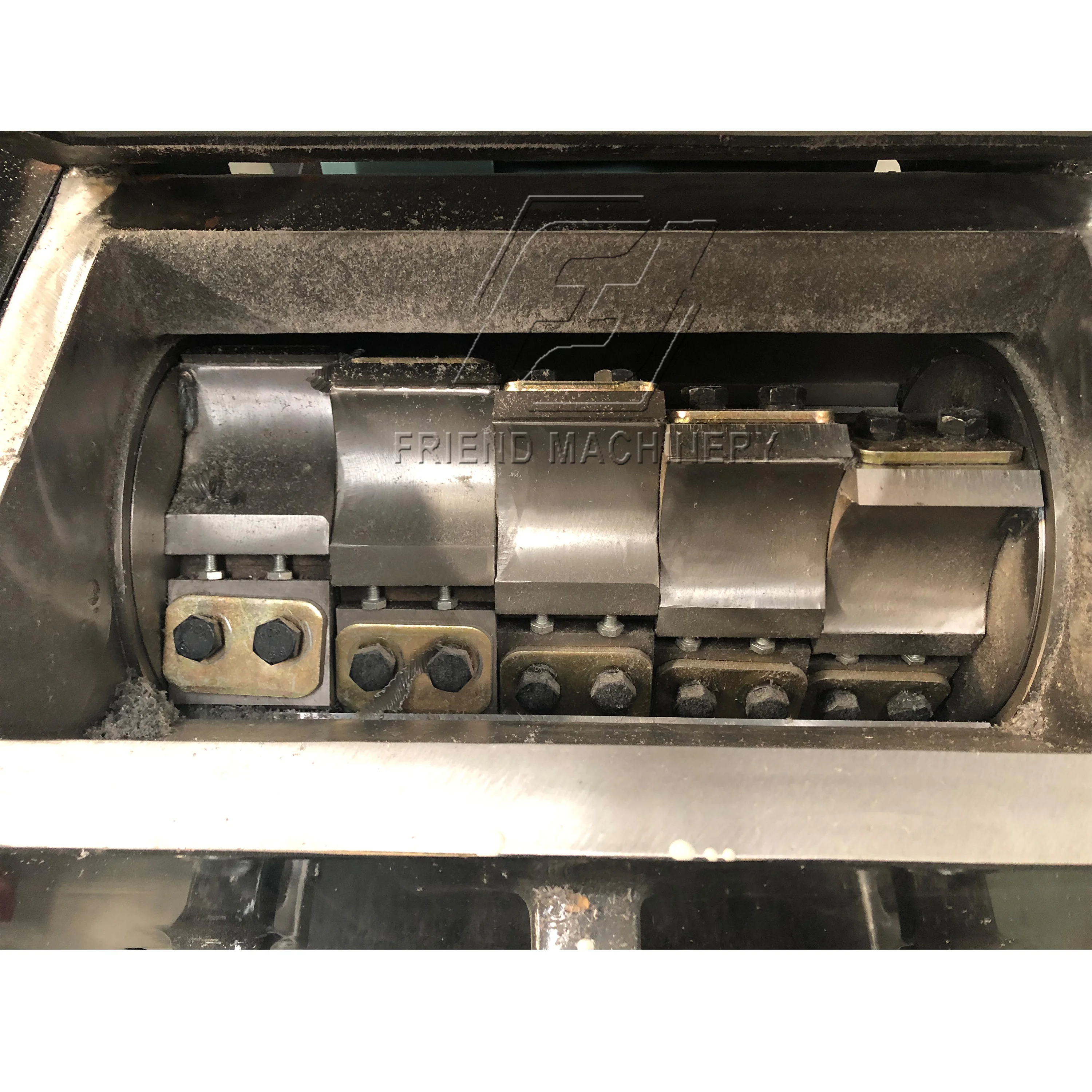

1. Compact design saves space Inclined upper and lower split case for easy blade replacement.

2. High safety factor bearings reduce the probability of bearing damage.

3. The rotor and the box body are integrally processed to ensure the shearing clearance between the moving knife and the fixed knife.

4. Both ends of the knife roller are equipped with replaceable wear plates.

5. Standard models can be equipped with air delivery devices.

6. Independent control box, Siemens PLC

| Model | PC300 | PC400 | PC500 | PC600 | PC800 | PC1000 |

| Power | 5.5 | 7.5 | 15 | 18.5-22 | 22 | 15 |

| Rotating blade | 9 | 12 | 15 | 18 | 24 | 34 |

| Fixed blade | 2 | 2 | 2 | 4 | 4 | 9 |

| weight(kg) | 480 | 660 | 1000 | 1500 | 1800 | 2000 |

The main purpose

Hammer crushers are used to break a variety of medium hard and abrasive materials. The compressive strength of the material does not exceed 100 MPa, and the water content is less than 15%. The materials to be crushed are coal, salt, white Asia, gypsum, brick, limestone and the like. It is also used to crush waste of wood, paper and broken asbestos cement with strong fiber structure, elasticity and toughness to recover asbestos fiber and so on.

The main working part of the hammer crusher is a rotor with a hammer (also called a hammer). The rotor consists of a main shaft, a disc, a pin and a hammer. The motor drives the rotor to rotate at high speed in the crushing chamber. The material is fed into the machine from the upper feed port, and is crushed by the impact, impact, shearing and grinding action of the high-speed moving hammer. In the lower part of the rotor, a sieve plate is provided, and the size of the pulverized material smaller than the mesh size is discharged through the sieve plate, and the coarse-grained grade larger than the mesh size is retained on the sieve plate and continues to be struck and ground by the hammer, and finally passed through the sieve plate. Exhausted from the machine.

Zhangjiagang Flander Machinery Co., Ltd. is a national designated enterprise specializing in R&D, production and sales of plastic machinery. The company continuously introduces advanced technology at home and abroad, pays attention to technological transformation, and continuously develops new products. The main products are plastic twin-screw extruder, series single-screw extruder, various pipe / sheet / profile equipment, stainless steel tube coating equipment, 3D screen printing equipment, all kinds of plastic cleaning and recycling granulation and various auxiliary machines and CAT5 , 6 and 7 data line manufacturing equipment.

Zhangjiagang Flanders Machinery Co., Ltd. will unremittingly strive to achieve self-transcendence in technology and service, create and provide truly valuable products for customers, and satisfy the bright future of customers. The integrity, strength and product quality of Zhangjiagang Flanders Machinery Co., Ltd. have been recognized by the industry. Welcome friends from all walks of life to visit Zhangjiagang Flanders Machinery Co., Ltd. to guide and negotiate business.

1.Are you a factory or a trading company?

A:We are a factory

2.Where is your factory located?How can i visit there?

A:Our factory is in jiangsu zhangjiagang,You can fly to Shanghai airport directly. We welcome you to visit our factory.

3.What is your factory mainly produce?

A:plastic extruder production line,Complete data cable manufacturing equipment and auxiliary equipment.