Высококачественная прочная легкая мраморная платформа

- Категория: Other Measuring & Gauging Tools >>>

- Поставщик: Hebei,Desheng,Measuring,Tool,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.93 $* | 0.72 $* |

| Aug-17-2025 | 0.99 $* | 0.32 $* |

| Jul-17-2025 | 0.7 $* | 0.53 $* |

| Jun-17-2025 | 0.40 $* | 0.34 $* |

| May-17-2025 | 0.96 $* | 0.86 $* |

| Apr-17-2025 | 0.57 $* | 0.53 $* |

| Mar-17-2025 | 0.89 $* | 0.68 $* |

| Feb-17-2025 | 0.61 $* | 0.33 $* |

| Jan-17-2025 | 0.72 $* | 0.96 $* |

Характеристики

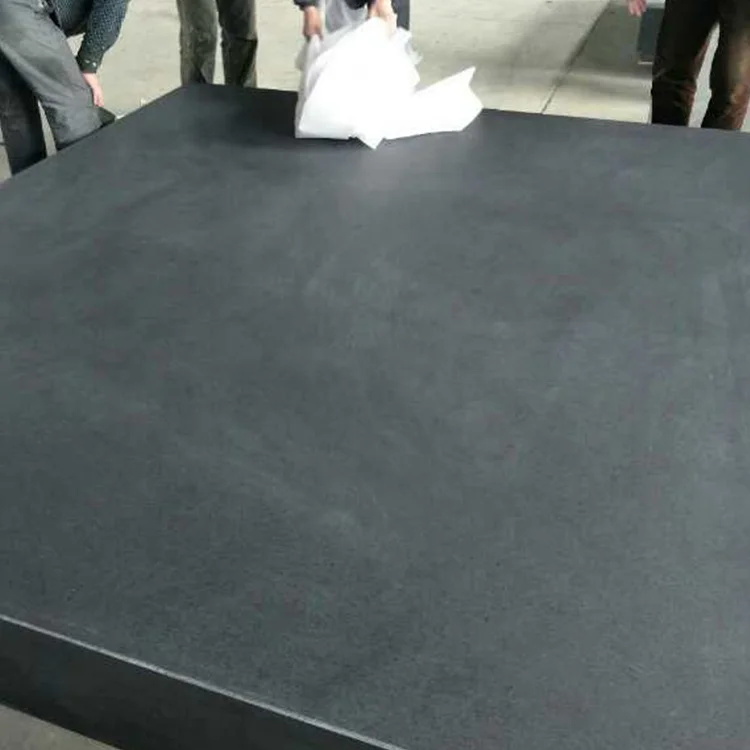

Sturdy light Marble Platform granite inspection table plat

The advantages are high precision, no static electricity, durability, high measurement accuracy. The shape of the working surface includes rectangles, squares, circles, etc. Besides, V-shaped, T-shaped, U-shaped grooves, dovetail grooves, round holes, long holes, etc. These also can be machinable. It is a flat reference measuring tool for workpiece, equipment inspection, scribing, assembly, welding, assembly, and riveting.

Generally used as a reference positioning surface in testing. Work surface is as a planar reference for inspection and scribing. Use this datum surface to compare with the actual surface of the workpiece being tested to determine the error value. The standard specifications of the granite surface plate are flat and the granite surface plate can also be slotted or perforated. Our company can make components or bases according to user requirements.

- There should be no defects such as sand holes, pores, cracks, slag inclusions, shrinkage, scratches, bumps, rust and other defects that seriously affect the appearance and performance of the working surface of the granite surface plate.

- The depression or corner on the non-working surface of the granite surface plate allows repairing.

- The granite surface plate should be made of fine-grained, densely structured gabbro, diabase, granite (the biotite should be less than 5%, the elastic modulus should be greater than 0.6x10-4kg/cm 2 , and the water absorption should be less than 0.25%). The hardness of the working surface should be greater than 70hs.

- The allowable value of the surface roughness R of the working surface is 0.32—0.63μm, and the side is 10μm.

- The vertical tolerance of the side of the granite surface plate to the working surface and the vertical tolerance of the adjacent sides of the plate are in accordance with the 12th level specified in GB/T1184.

Rank Work surface accuracy

(Temperature 20 ° C,d is diagonal length,unit is mm.)

Plane fluctuation of the working face 000 1×(1+d/1000)um 2μm 00 2×(1+d/1000)um 4μm 0 4×(1+d/1000)um 8μm 1 8×(1+d/1000)um 16μm

- Before use

- There should be a qualified mark, valid use period or other proof.

- There should be no defects such as burrs, scratches, bruises, rust, etc. on the measuring surface.

- The measured part shall not have defects such as burrs, scratches, bumps, scratches, rust, etc.

- The temperature of the granite surface plate and the device under test should be as uniform as possible to prevent measurement errors.

- Before use, it should be inspected according to the specified requirements and methods.

- Using

- During the use, avoid placing heavy objects on the working surface of the granite surface plate for a long time. The granite surface plate used for the first time should be leveled again after two months of the first leveling.

- The granite surface plate is fragile. During the process of use, it is necessary to avoid excessive collision between the workpiece and the working surface of the platform to prevent damage to the working surface of the platform and affect the accuracy of the working surface.

- It is forbidden to place overheated workpieces (such as soldering irons) directly on the surface.

- The weight of the workpiece should not exceed the rated load of the platform, otherwise the quality of the work will be reduced, the platform will be destructively deformed, and the structure of the platform may be damaged, making it unusable.

- Keep it clean and any stains on the platform may affect the measurement accuracy.

- After use

- After use, remove the stain on the granite surface plate with a neutral detergent. When cleaning, wipe the surface of the platform with a soft cloth dampened with detergent. After the cleaning is completed, the surface of the platform is free of oil and dirt, and no other particles adhere to it, and the handle is smooth and free from stagnation.

- Do not use hard brushes and abrasive cleaners.

- After use or cleaning, the platform should be covered with plastic or plastic sheets to prevent dust pollution and protect the working surface from damage.