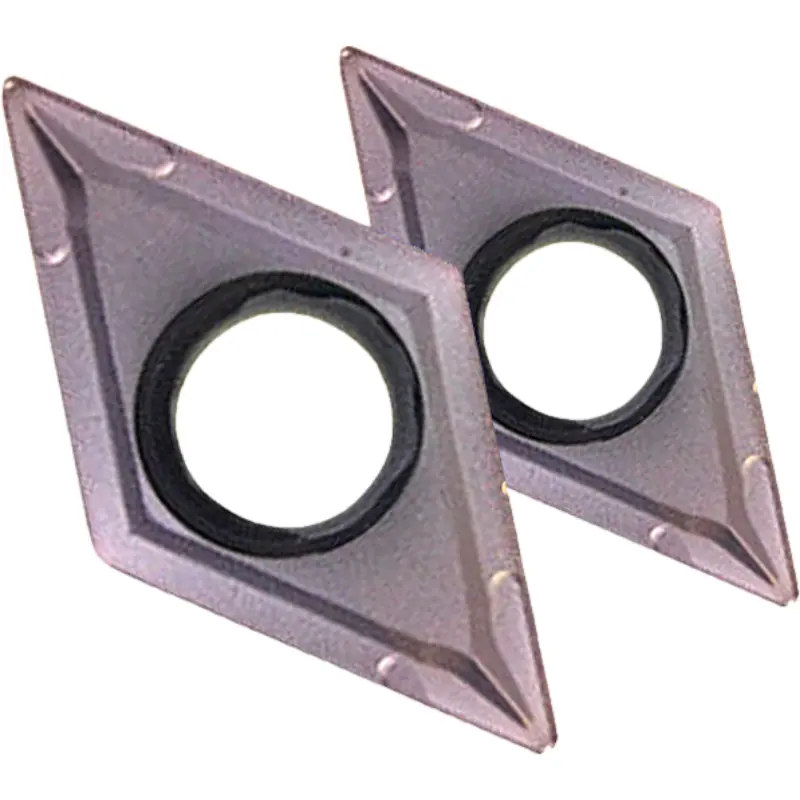

Заводской высококачественный керамический резак токарные инструменты керамические

- Категория: Токарный инструмент >>>

- Поставщик: Zhuzhou,Uko,Cemented,Carbide,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.62 $* | 0.96 $* |

| Aug-16-2025 | 0.30 $* | 0.53 $* |

| Jul-16-2025 | 0.78 $* | 0.97 $* |

| Jun-16-2025 | 0.56 $* | 0.99 $* |

| May-16-2025 | 0.26 $* | 0.34 $* |

| Apr-16-2025 | 0.30 $* | 0.94 $* |

| Mar-16-2025 | 0.40 $* | 0.78 $* |

| Feb-16-2025 | 0.17 $* | 0.3 $* |

| Jan-16-2025 | 0.40 $* | 0.60 $* |

Характеристики

Product Description

Our Advantages

Details Images

TNMG160404L-S

TNMG160408L-S

TNMG160408L-S

TNMG160404R-S

TNMG160408R-S

TNMG160408R-S

TNMG160404L-S1

TNMG160408L-S1

TNMG160404R-S1

TNMG160408R-S1

TNMG160404L-LR

TNMG160408L-LR

TNMG160404R-LR

TNMG160408R-LR

TNMG160404-TS TNMG160408-TS

Basic Grade

Grade | Information |

UK215 | It is suitable for finishing and semi finishing of steel parts (< 40HRC carbon steel, alloy steel, tool steel, pre hardened steel), stainless steel (< 35HRC), cast iron (< HB350) and aluminum alloy series. Excellent strength, fracture toughness and surface finish. |

UK225 | It is suitable for finishing and semi finishing of steel parts (> 40HRC carbon steel, alloy steel, tool steel and pre hardened steel). High wear resistance, high strength and toughness, excellent surface finish. |

Package

10pcs/box

Customer Usage Scenarios

Top Equipment

Packing & Delivery

Packing Details : 10 PCS to a box

Delivery Details : For stocked items, we will deliver the products within 3-5 days after payment confirmed.

Tool Holder Matching

Our Company

Cermet inserts use FAQ

1. Worn face

Influence: Gradually changing workpiece size or surface finish

Reason: Line speed is too high, reaching tool life

Solution: Adjust processing parameters, such as reducing line speed and using more wear-resistant inserts

Reason: Line speed is too high, reaching tool life

Solution: Adjust processing parameters, such as reducing line speed and using more wear-resistant inserts

2. The insert broke

Influence: Sudden change in workpiece size or surface finish, sparks on the surface

Reason: Inappropriate parameter settings, inappropriate choice of insert material, poor workpiece rigidity, unstable blade clamping

Solution: Check whether the parameter setting is reasonable and select the corresponding tool according to the workpiece material

Reason: Inappropriate parameter settings, inappropriate choice of insert material, poor workpiece rigidity, unstable blade clamping

Solution: Check whether the parameter setting is reasonable and select the corresponding tool according to the workpiece material

3. Severe fracture

Influence: Sudden unpredictable conditions occur, resulting in scrap of tool holders or defective and scrapped workpieces

Reason: The processing parameters are set incorrectly, and the vibrating workpiece or insert is not installed in place.

Solution: Set reasonable processing parameters, should reduce the feed amount and reduce the chip selection of the corresponding processing inserts, strengthen the rigidity of the workpiece and the insert.

Reason: The processing parameters are set incorrectly, and the vibrating workpiece or insert is not installed in place.

Solution: Set reasonable processing parameters, should reduce the feed amount and reduce the chip selection of the corresponding processing inserts, strengthen the rigidity of the workpiece and the insert.

4. Scum tumor

Influence: Inconsistent workpiece size, poor surface finish, and fluff or burrs on the surface

Reason: Cutting speed is too low, feed is too low / not sharp enough

Solution: Increase cutting speed and use sharper inserts for feed

Reason: Cutting speed is too low, feed is too low / not sharp enough

Solution: Increase cutting speed and use sharper inserts for feed