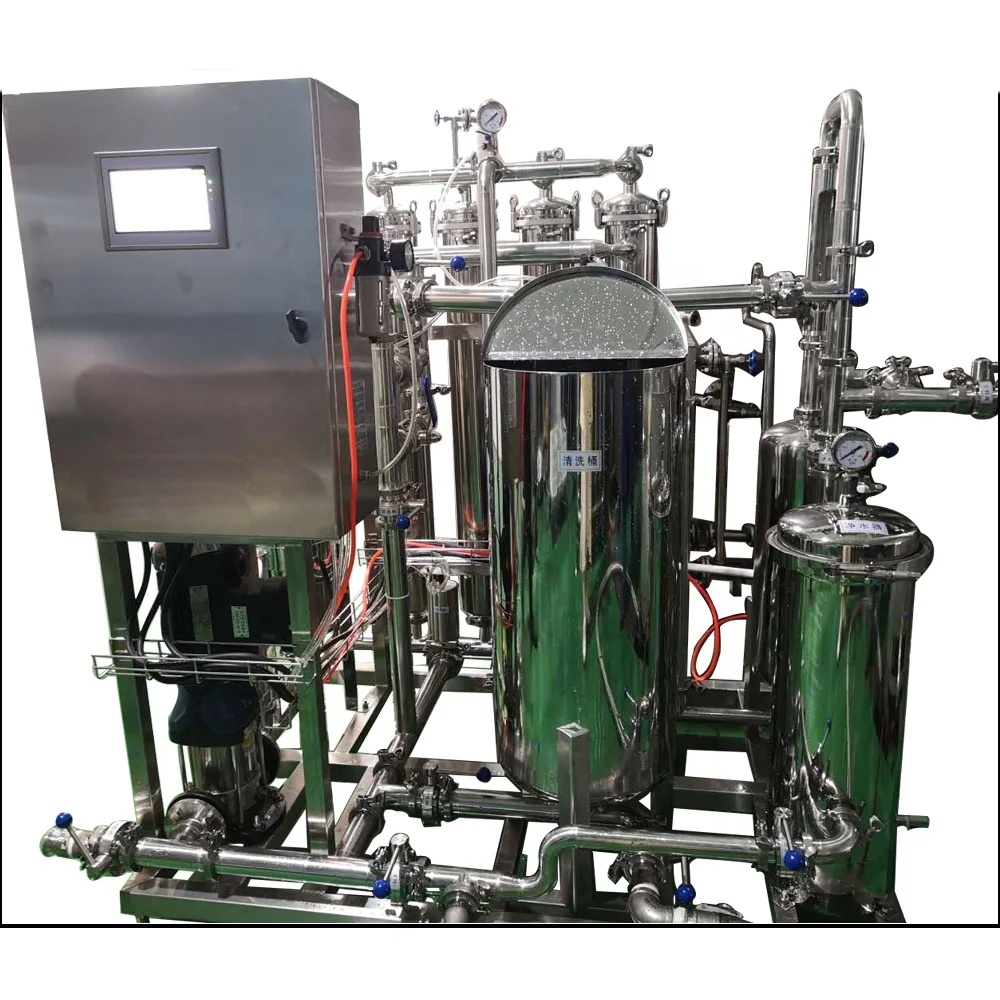

Оборудование для производства фильтров из нержавеющей стали машина

- Категория: Очистное оборудование >>>

- Поставщик: Guangzhou,Vocee,Membrane,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 11900.64 $* | 12495.48 $* |

| Aug-18-2025 | 11800.64 $* | 12390.96 $* |

| Jul-18-2025 | 9900.24 $* | 10395.33 $* |

| Jun-18-2025 | 11600.56 $* | 12180.3 $* |

| May-18-2025 | 10100.65 $* | 10605.40 $* |

| Apr-18-2025 | 11400.64 $* | 11970.8 $* |

| Mar-18-2025 | 11300.11 $* | 11865.91 $* |

| Feb-18-2025 | 11200.66 $* | 11760.93 $* |

| Jan-18-2025 | 11100.38 $* | 11655.2 $* |

Характеристики

Pure Physical Interception style wine filter machine

Cross-flow membrane sterilization microfiltration system is a high-tech equipment, It is a device specially designed for the liquid filtration, sterilization and clarification.

According to different separation objects, there are yellow wine filtration system, soy sauce filtration system, rice vinegar filtration system,fruit wine filtration system and red wine filtration system, etc..

The following pictures are the comparison before and after filtering

Main technical parameters of the equipment | ||

Interception aperture | 0.18um | |

Sterilization rate | ≥99% | |

PH range | 1-14 | |

Temperature | <45℃ | |

Operation pressure | <0.25Mpa | |

Cleaning method | CIP | |

Controller | PLC Automatic | |

Operation | 24hrs | |

Features of the machine

1,Fixed pore size retention, no filter material added, excellent filtration quality, high clarity of liquid discharge, and the sterilization effect is over 99.5%. At the same time, the filtration quality is completely guaranteed by the equipment, avoiding various instability of diatomite filtration factor.

2, Using high-strength, acid and alkali resistant, anti-oxidation, can adapt to high-intensity frequent backwash cleaning and high concentration, long-term chemical cleaning.

3, can be adapted to filter the dragon fruit wine with high turbidity directly,

coarse filtration, fine filtration are completed at one time, directly replace the diatomite coarse filter and cardboard fine filter.

4,The most practical modular separation unit design, compared with diatomite filtration, not only the small volume of the remaining wine in the equipment, but also realize the operation and further concentration of some separation modules, On the basis of adapting to large-scale production, it can better adapt to the production needs of multi-variety and small-volume products during non-production season.

Advantages of the machine

1.Significantly improve the quality of product filtration

Fruit juice using cross-flow membrane filtration can significantly improve the clarity, the wine is more lustrous after filtration, and retain more than 99.5% of the microorganisms in the liquor, so that the hygienic indicators of the wine meet the national standards. And the membrane filtration has no effect on the physical and chemical indicators such as alcohols, acids and dry extracts in fruit wine.

2.The filtration process is more simpler and more reliable

(1) The equipment has high automation degree, easy operation, overload protection during operation, safe and reliable, so no human monitoring or operation is required.

(2)Membrane separation system is a pure physical interception of the fixed pore size, so the liquid output index is not affected by the filter material, personnel operation ability, etc., and is quite stable, and the quality control of the finished product is also easier.

(3) Compared with the diatomite filter and the cardboard fine filter, the application of the device does not require a full-time filter person, and since the film has no adsorption, the loss is almost zero.

(4)The equipment connection pipelines, containers and pumps are all made of sanitary grade stainless steel, which meets the hygiene requirements of the food industry.

Our Main Products:

Ultra-filtration & MBR membrane, UF plant, MBR system, Nanofiltration equipment, RO equipment, EDI ultra pure water equipment,Wine clarfication equipment, water recycling,sea water desalination,material concentration and separation equipment and other membrane filtration systems.