Машина для изготовления алюминиевых металлических блоков высокой плотности по заводской

- Категория: Chamfering Machines >>>

- Поставщик: Gongyi,Hengyuan,Industry,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 23800.32 $* | 24990.26 $* |

| Aug-17-2025 | 23600.86 $* | 24780.60 $* |

| Jul-17-2025 | 19800.86 $* | 20790.27 $* |

| Jun-17-2025 | 23200.54 $* | 24360.21 $* |

| May-17-2025 | 20200.93 $* | 21210.25 $* |

| Apr-17-2025 | 22800.23 $* | 23940.46 $* |

| Mar-17-2025 | 22600.2 $* | 23730.92 $* |

| Feb-17-2025 | 22400.36 $* | 23520.71 $* |

| Jan-17-2025 | 22200.70 $* | 23310.26 $* |

Характеристики

High-density factory price aluminum metal block making machine Cell/whatsapp: 0086 18039505731

Product description of aluminum metal block making machine

Hydraulic high-density block making machine are mainly used to extrude raw materials into high-density columnar cakes or blocks without any adhesives added.

The extruded cakes or blocks can be directly placed into furnaces.

The features of aluminum metal block making machine

1.adopting advanced hydraulic driving technology and high abrasion-resistant oil seals.

2.the oil cylinders are processed and assembled through the newest technologies so as to prevent the pressure in the oil cylinders from being reduced in the continuous operation.

3.durability, stable running, computer-aided control,high automation,low fault rate,and easy maintenance.

Major technological date

(the density and weight of cakes and blocks vary with the raw materials)

Model | Capacity

(iron) | Capacity (aluminum) | Block Diameter (mm)

| Power

(kw) | Machine Weight (t) | Machine demision (m) |

300 | 600kg/h | 230kg/h | 100 | 22 | 4.8 | 0.81x0.81x3.5m |

400 | 800kg/h | 330kg/h | 110 | 33 | 5.5 | 1x1x3.8m |

700 | 1600kg/h | 650kg/h | 160 | 49 | 13.5 | 1.1x1.1x4.2m |

Remarks:

Raw materials.

metal filings(as iron,copper and aluminum,etc.),metal powders(as iron,aluminum,copper and lead),smelting additives and sponge iron.

Steel chips

Whether it's turnings, chips, filings, shavings or sludge, the steel you use is being wasted as it gathers on your shop floor.

Steel Briquettes

Steel briquetting press can double the value you get for your steel scrap compared to loose chips or other recycling methods.

Aluminum Chips

Aluminum scrap metal, in the form of turnings, filings, chips and shavings, piling up on the equipment and floor. taking up the valuable floor space.

Aluminum Briquettes

Squeeze value from aluminum waste.

Compress aluminum scrap into dense briquettes and separate any fluids used in the metalworking process from the scrap metal.

Copper Chips

What do you do with your copper scrap? If you are like many manufacturers, the scrap is stored in your yard, then hauled away (at your expense) to be disposed of.

It's time to turn copper waste into an asset.

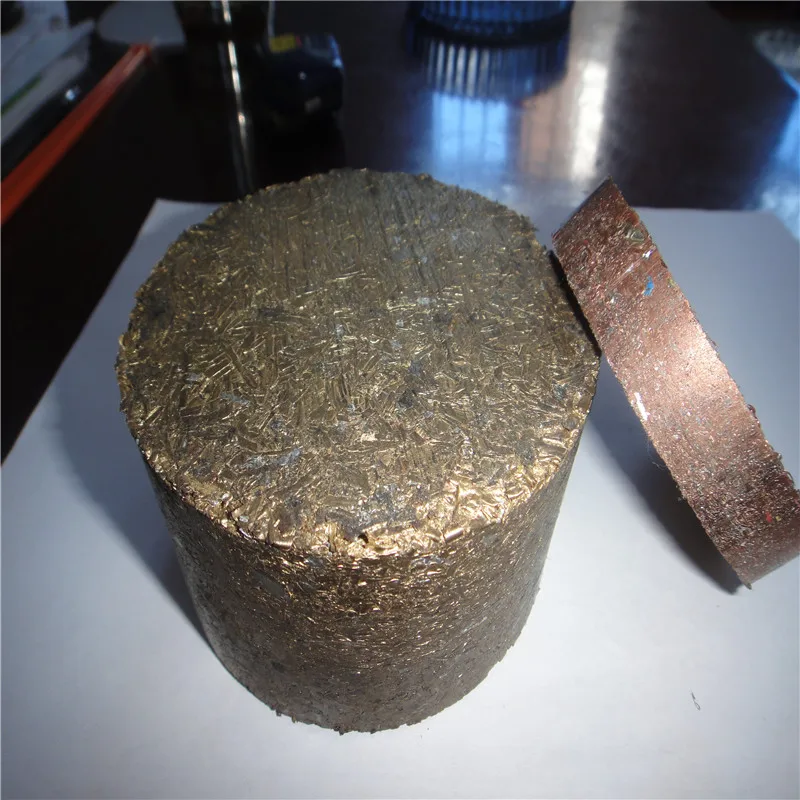

Copper Briquettes

Copper briquetting press to turn your scrap copper into compressed briquettes that are easier to handle, store and transport and can be sold for recycling.

Pre-sales service:

1.Professional introduction and suggestion on raw material, machine selection, workshop condition, feasibility analysis, etc.

2.Reasonable recommendation (according to the raw material, capacity and the size of block)

3.24 hours on-line service.

4.Welcome to visit our factory anytime, if you need, we can make invitation card for you.

After-sales service:

1.Engineer available to help with installation and test the machine overseas if needed.

2.Warranty one year after delivery.

3.Training support to the operator until they are satisfied.

4.Recall clients regularly, get feedback in time, keep well communication with each other.

Any other questions,feel free to contact me.