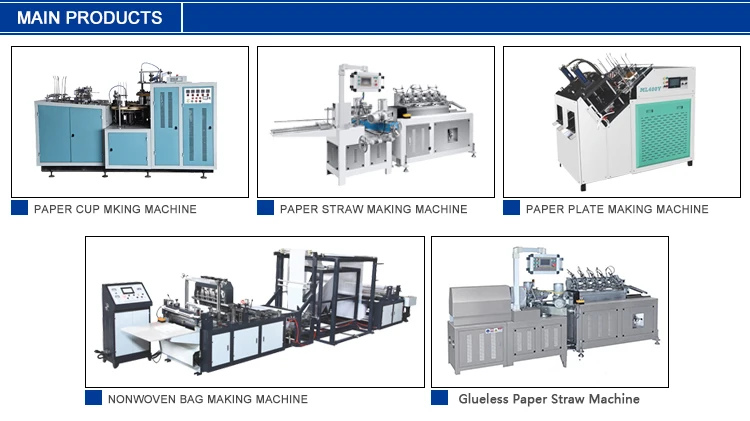

Машина для производства нетканых мешков Ruian

- Категория: Bag Making Machines >>>

- Поставщик: Pingyang,China,World,Import,And,Export,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 972942.78 $* | 1021589.6 $* |

| Aug-17-2025 | 964766.76 $* | 1013004.1 $* |

| Jul-17-2025 | 809422.3 $* | 849893.59 $* |

| Jun-17-2025 | 948414.2 $* | 995835.23 $* |

| May-17-2025 | 825774.51 $* | 867063.71 $* |

| Apr-17-2025 | 932062.77 $* | 978665.13 $* |

| Mar-17-2025 | 923886.23 $* | 970080.32 $* |

| Feb-17-2025 | 915710.86 $* | 961496.23 $* |

| Jan-17-2025 | 907534.16 $* | 952911.86 $* |

Характеристики

Performance:

It adopts the PLC programmable logic controller as main control, touch screen. (Made in Taiwan)

Unwinding tension is controlled by magnetic system.

Edge positioning control system .

Equipped with photoelectric tracking material, stopping automatically when the material is finished.

Stepping motor for feeding material.(YASKAWA servo motor EXTRA cost ) for your choice.

Photoelectrical eyes for tracking printed bag and the feeding error.

Vector inverter as speed regulator.

Ultrasonic for cross sealing for export standard quality.

Automatic accounting and set table counting alarm.

Unit | Specification | Model and origin |

|

|

|

Mainly Technical Parameter | Type | CW-B700 Non Woven Bag Making Machine |

| Roller width | 50-1200mm |

| Bag making speed | 20-120pcs/min |

| Bag length | 150-600mm |

| Bag width | 100-1000mm |

| Material thickness | 20-100g |

| Power supply | 220v,380v |

| Total power | 13Kw |

| Overall size(L*W*H) | 8000*1650*1850mm |

Mainly machine | Blanking unit | One set |

| Horizontal traction unit | One set |

| Vertical fold unit | One set |

Roller unit | Blanking way | Manual Expansion Control |

| Roller control device | Expansion shaft (or taper sleeve fastening through mandrel 30mm) |

| Roller diameter | φ1000mm |

Controller and Roller System | Correcting deviation device | Automatic correcting deviation system |

| Automatic shutdown system | Photoelectric eye |

| Plate | Stainless steel |

| Power control system | Special motor tension driver system |

| Ultrasonic system | 70mm 3 pieces,160mm 4 pieces(shanghai) frequency 20K power 1000W |

| Temperature control system | Temperature control unit |

| Operation | man-machine interface touch control |

| Relay | SCHNEIDER |

| Pneumatic component | LEIERDA |

Brand of machine parts | Temperature gauge | Keqiang |

| Switch | Zhengtai |

| Inverter | Taizhou devo |

| converter motor | Lichao(made in shanghai) |

| Main Touch Screen | Microsoft(Taiwan) |

| Bearing | Haerbin |

1.Q:Are your company a manufacturer or trading company?

A:We are professional manufacturer of paper plate machine with more than ten years machinery experience in Ruian, China.

2.Q:Where is your factory? How can I get there?

A:Our factory is located in wenzhou City, Zhejiang Province. It takes about three and a half hours by train from Shanghai to our city. all of our customers can take the flight to wenzhou international airport first, and then we can send a car to pick up you.

3. Q:How can I get the samples?

A:We can supply some free samples. Besides, the express charges will be paid in your side.

4. Q:Before inquiry, what information should I provide?

A: 1.Paper plate size, such as diameter, depth, length,width etc.