Оборудование для производства нетканых сумок/автоматическая машина плоских сумок из нетканого материала/нетканых

- Категория: Bag Making Machines >>>

- Поставщик: Pingyang,China,World,Import,And,Export,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.28 $* | 0.67 $* |

| Aug-17-2025 | 0.35 $* | 0.71 $* |

| Jul-17-2025 | 0.47 $* | 0.60 $* |

| Jun-17-2025 | 0.70 $* | 0.16 $* |

| May-17-2025 | 0.7 $* | 0.74 $* |

| Apr-17-2025 | 0.79 $* | 0.43 $* |

| Mar-17-2025 | 0.18 $* | 0.89 $* |

| Feb-17-2025 | 0.20 $* | 0.79 $* |

| Jan-17-2025 | 0.14 $* | 0.76 $* |

Характеристики

CW-C700 Non Woven D-cut Bag Making Machine

Process Flow:

Roll material --Bag Mouth folding and sealing -- Drawstring-- Folding -- Bottom gusset -- Position -- D-cut Punching-- Edge sealing -- Cutting--Finished Product

Type | CW-C700 |

Material Width | 50-1300mm |

Production speed | 20-120pcs/min |

Bag Height | 200-600mm |

Bag Width | 100-800mm |

Material basis weight | 30-120g/m2 |

Power supply | 380V/220v |

Total Power | 12kw |

Overall size | 7600*1900*2100mm(L*W *H) |

weight | 2000KG |

Manual punching machine production speed | 40-50 pcs/min |

7.5 KW Screw Air compressor + Air Tank + Dryer

Compressed air supply equipment.We suggest to use screw air compressor and equipped with air tank and refrigerate air dryer, which can supply clean,dry compressed air to improve the stability of the machine running and prolong the machine’s service life.

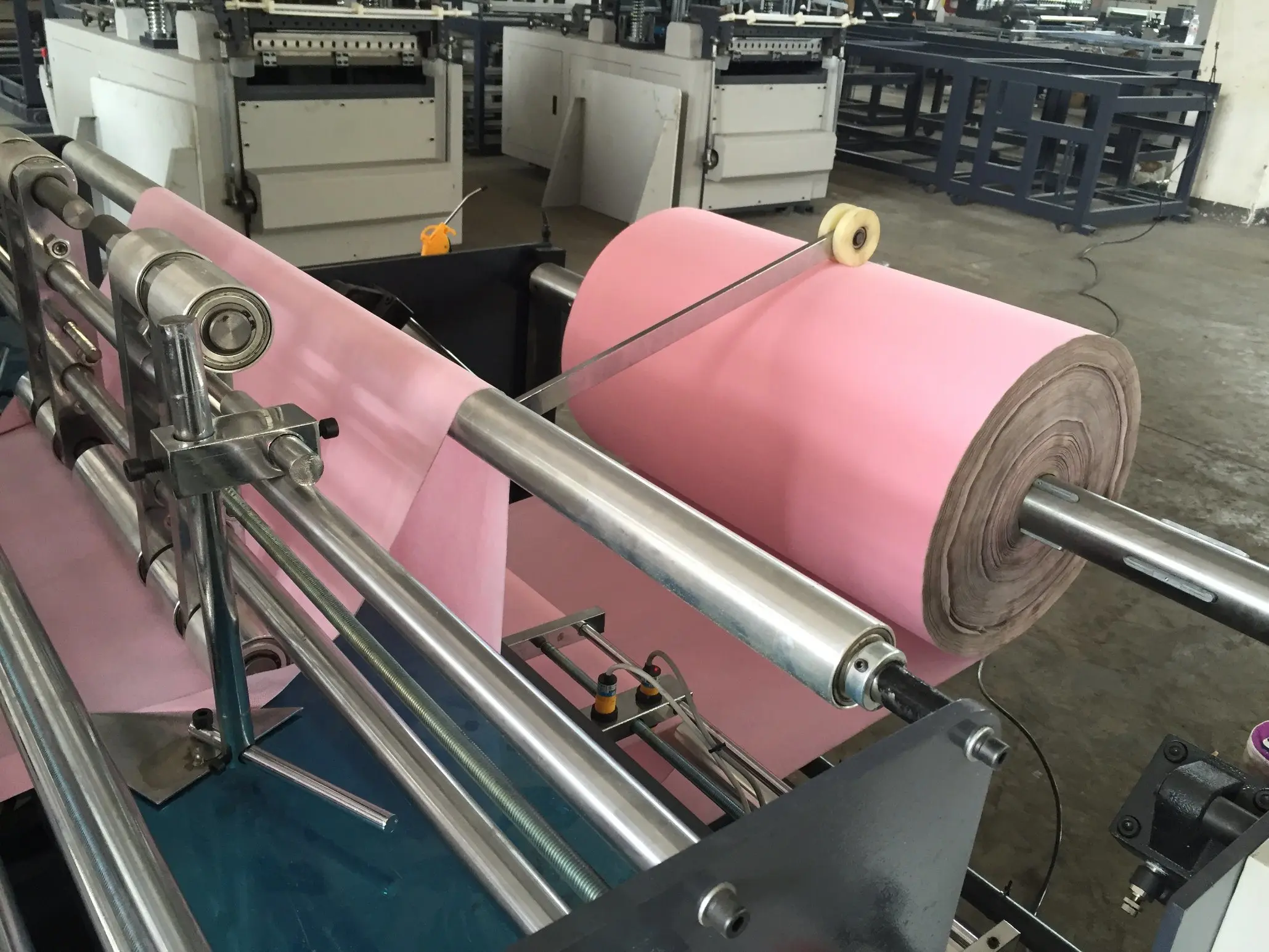

1. Unwinding : It is equipped with an automatic unwinding device, so there is no need for you to lift the fabric roll and you can also operate the machine alone.The automatic unwinding-stopping device: it will stop unwinding after using up the fabric so that save time and improve working effect. The unwinding shaft is called air swelling shaft, which is convenient.What’s more, there is an automatic EPC motor to rectify the fabric position |  |

2. Flat folding : This part is for bag mouth folding &drawstring. 2 sets 70mm ultrasonic round-head ultrasonic, which are used to fix the fabric folding part. |  |

3. Fabric Cross Folding : |  |

4. Insert edge / Insert bottom / T-shirt bag part : This part is used to insert bag bottom and t-shirt bag gusset. |  |

5.Electric-eye tracking part : This part is used for printed bag to ensure the right position of printed image. |  |

Part 6: D-cut punching unit : |  |

Part 7: Bag Sealing part: To seal the two sides of bag with ultrasonic . |  |

Part 8: Bag Cutting part : Cutting the finished non woven bag with cold cutter, then collecting the finished bag . |  |

1.Q:Are your company a manufacturer or trading company?

A:We are professional manufacturer of nonwoven bag machine with more than ten years machinery experience in Ruian, China.

2.Q:Where is your factory? How can I get there?

A:Our factory is located in wenzhou City, Zhejiang Province. It takes about three and a half hours by train from Shanghai to our city. all of our customers can take the flight to wenzhou international airport first, and then we can send a car to pick up you.

3. Q:What kind of bags can this machine produce

A:CW-C700 can make D cut bag and T-shirt/U cut(need auto/manual punch bag).

4. Q:How long is the warranty? How to be responsible

A: One year warranty, one year damaged parts will be free express to customers.

If the customer needs our factory engineer to go abroad to help the customer, the buyer shall pay for the visa, air ticket, hotel and food expenses of the seller's engineer, as well as the salary of $80 per person per day.