Профессиональная машина для добычи золота мини-цементная установка шаровая мельница испытания на обработку домашней

- Категория: Mine Mill >>>

- Поставщик: Henan,Chunyue,Import,&,Export,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 14280.94 $* | 14994.27 $* |

| Aug-16-2025 | 14160.63 $* | 14868.14 $* |

| Jul-16-2025 | 11880.59 $* | 12474.72 $* |

| Jun-16-2025 | 13920.31 $* | 14616.90 $* |

| May-16-2025 | 12120.88 $* | 12726.69 $* |

| Apr-16-2025 | 13680.54 $* | 14364.14 $* |

| Mar-16-2025 | 13560.61 $* | 14238.51 $* |

| Feb-16-2025 | 13440.41 $* | 14112.49 $* |

| Jan-16-2025 | 13320.2 $* | 13986.79 $* |

Характеристики

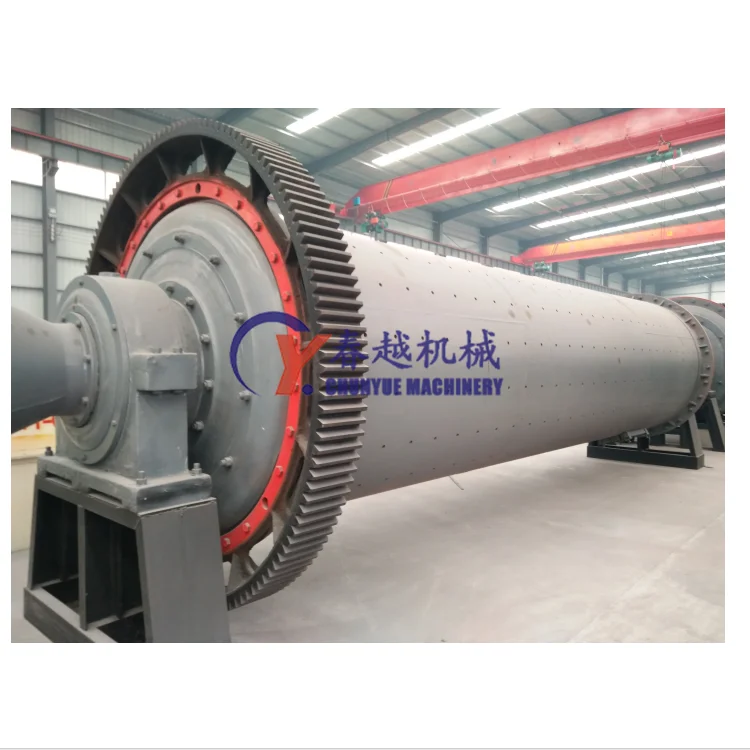

professional gold mining machine mini cement plant ball mill for home ore processing test

Ball Mill is the key equipment of crushing material, which is mainly used for single stage fine grinding, grinding, grinding circuit of grade two. Widely used in cement, silicate product, new building material, refractory, fertilizer, black and non-ferrous metals and glass ceramic industry. It is divided into dry method and wet grinding method. According to different ore discharging methods, it can be divided into lattice type and overflow type. Due to different unloading modes, it can be divided into grate type and overfall type.

(3) Mineral ball mill is an efficient tool for grinding many materials into fine powder.

(4) As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

(5) There are two ways of grinding: the dry way and the wet way.

(6) Ultimate particle size depends entirely on how hard the material you’re grinding is.

(7) Mineral ball mill have been used to grind glass, powder food products, create custom varnishes, make ceramic glaze, and powder various chemicals.

Composition of 1-3tph Mining Industrial small used milling machines small scale mining ball mill for sale :

This machine is mainly consists of feeding device, discharge device, rotating device, transmission devices (gear box, pinion gear, motor and electric control device). The hollow shaft is made of cast steel. The liner is replaceable. The gear wheel adopts casting gear hobbing. The wear-resisting liner is inlayed in the cylinder of ball mill.

The mineral ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft evenly. There are ladder liner, ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height to impact and grind the materials. And then the grinded materials are discharged through the discharging board.

Technical parameter of professional gold mining machine mini cement plant ball mill for home ore processing test :

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. or it is 15-25 work days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: T/T,Alibaba Trade Assurance or L/C

Q: “What’s the technique structure of ball mill machine?

A: Cast steel hollow shaft, lined with removable, rotary gear hobbing by casting process, the body inlaid cylinder liner wear, has good wear resistance. Smooth mill operation of the machine, reliable.

Q: “Can introduce the details of several issues when used ball mill to grind rocks?”

A: 1. Additional ball mill should be regularly in order to maintain the best ball mill loading.

2. Running regularly on the recirculation pump, piping and recycling containers to wash, cyclone should also be regularly switch, flush to prevent clogging.

3.Ball mill output should be in the best run, should not easily change the output.

Contact: Ms May Liu

Mail:May"at"chunyuetrading.com

professional gold mining machine mini cement plant ball mill for home ore processing test