Осадка для домашней птицы коров цыплят сточных вод

- Категория: Biogas >>>

- Поставщик: Shenzhen,Teenwin,Environment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.92 $* | 0.28 $* |

| Aug-19-2025 | 0.81 $* | 0.94 $* |

| Jul-19-2025 | 0.31 $* | 0.80 $* |

| Jun-19-2025 | 0.90 $* | 0.16 $* |

| May-19-2025 | 0.8 $* | 0.76 $* |

| Apr-19-2025 | 0.67 $* | 0.92 $* |

| Mar-19-2025 | 0.24 $* | 0.12 $* |

| Feb-19-2025 | 0.3 $* | 0.19 $* |

| Jan-19-2025 | 0.17 $* | 0.71 $* |

Характеристики

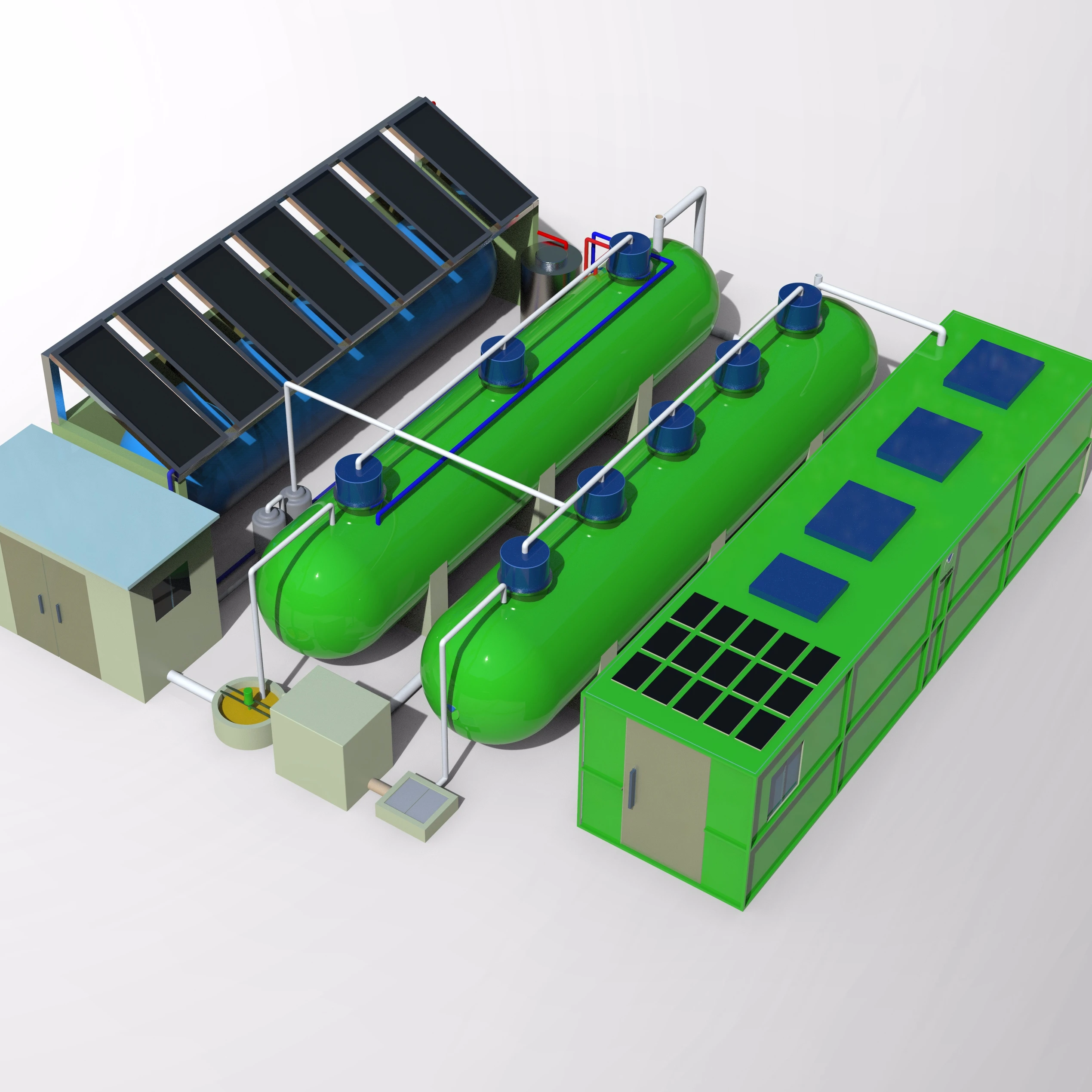

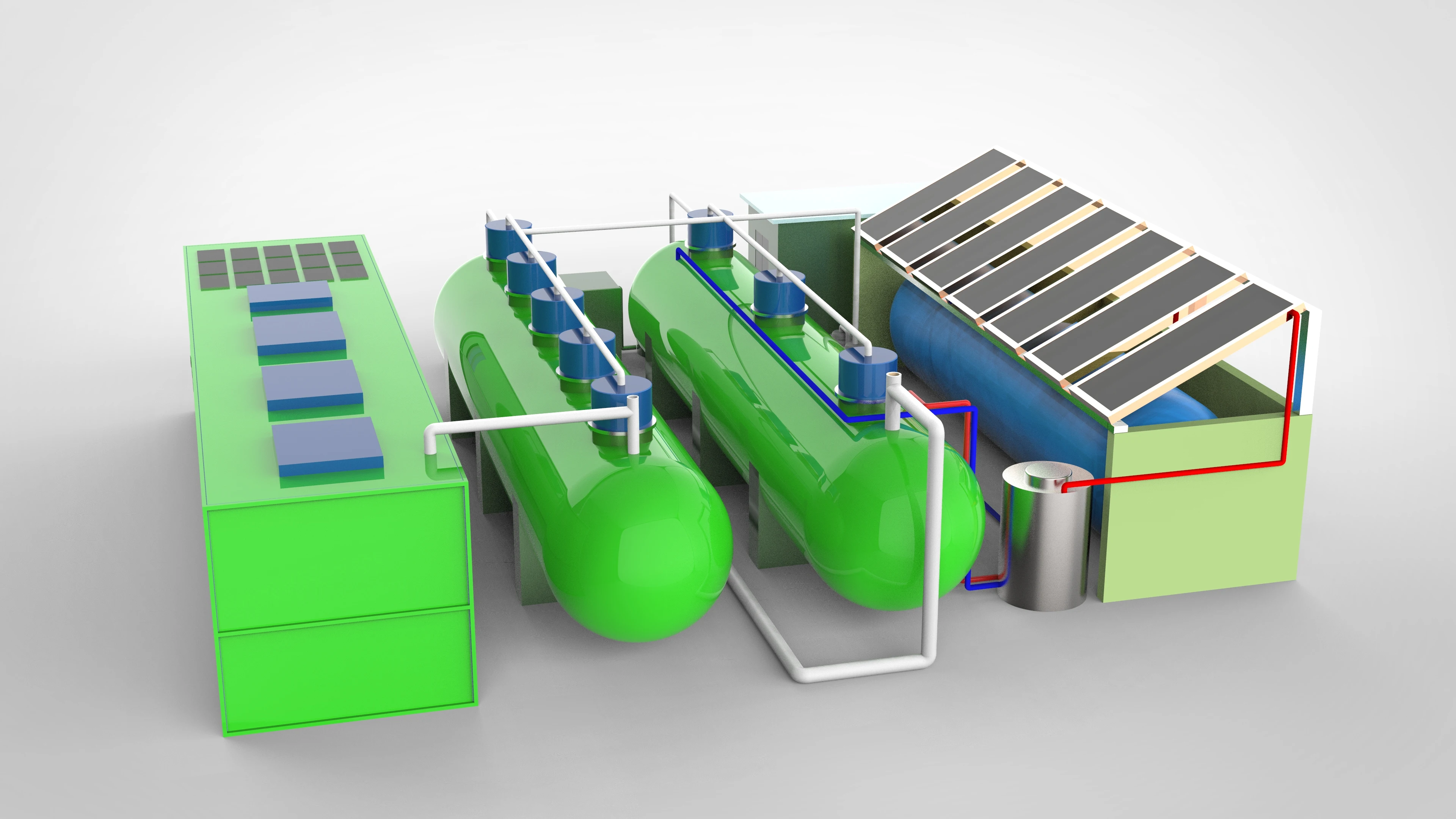

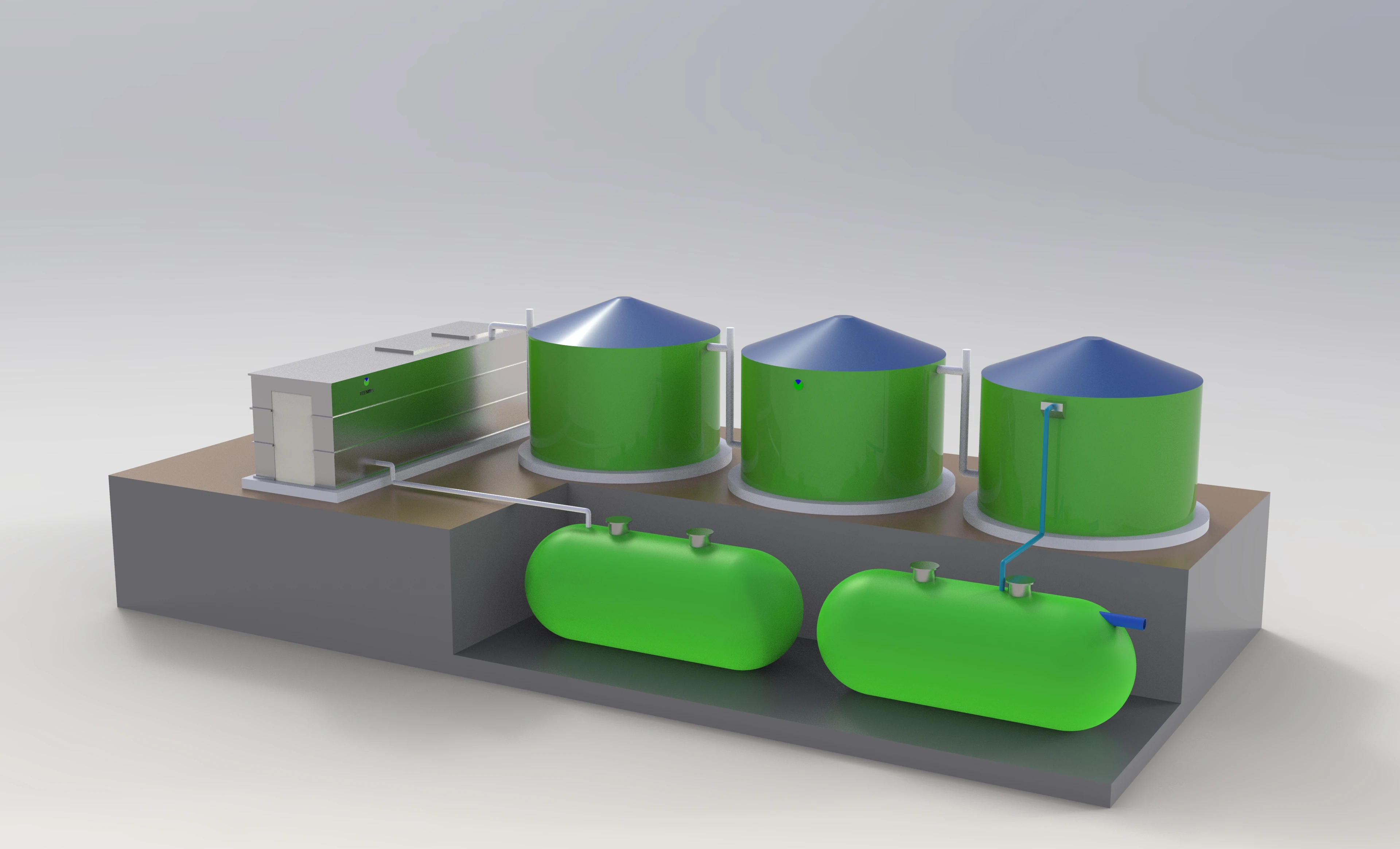

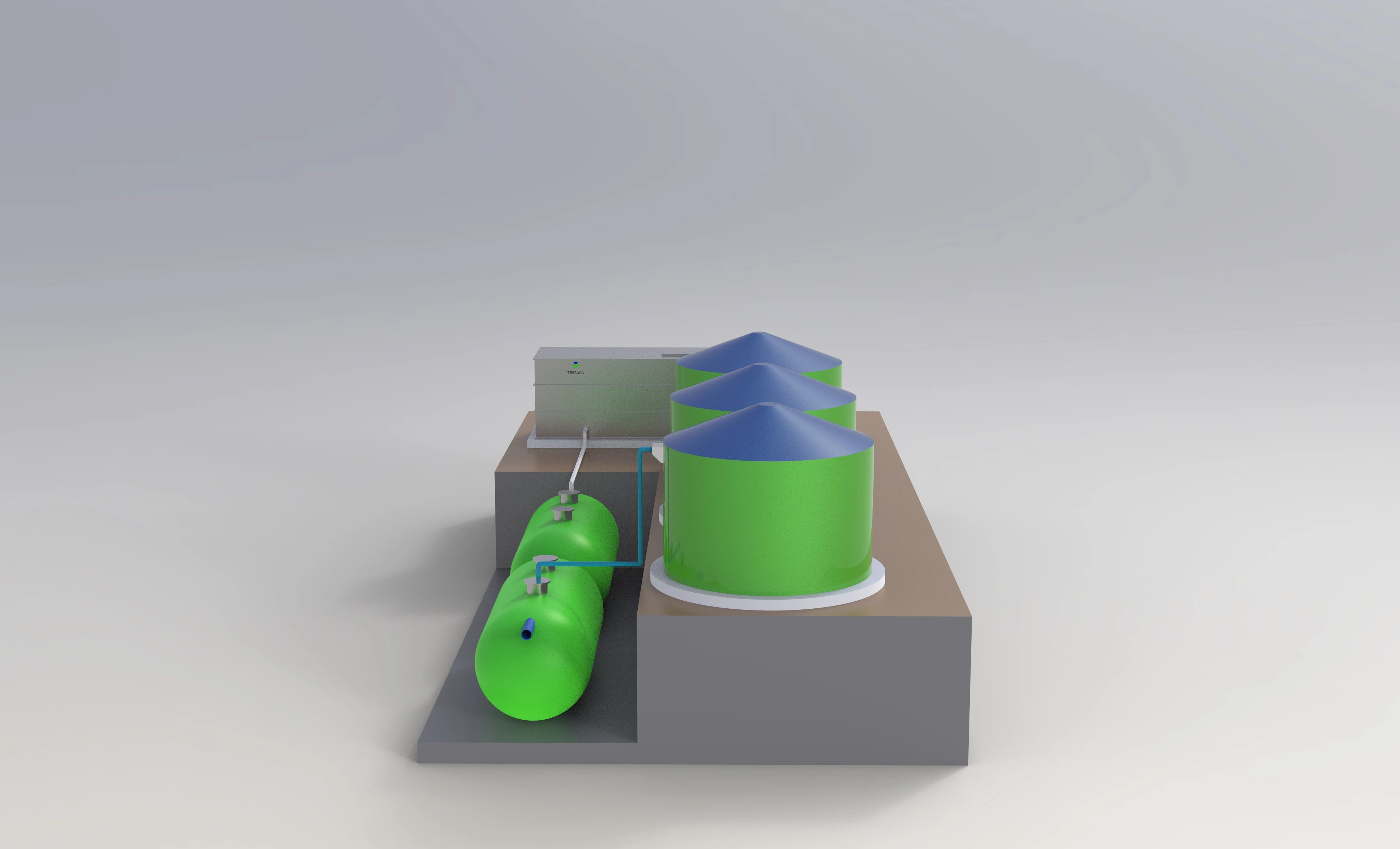

Teenwin animal cow chicken poultry slaughterhouse effluent wastewater offals manure treatment plant for abattoir

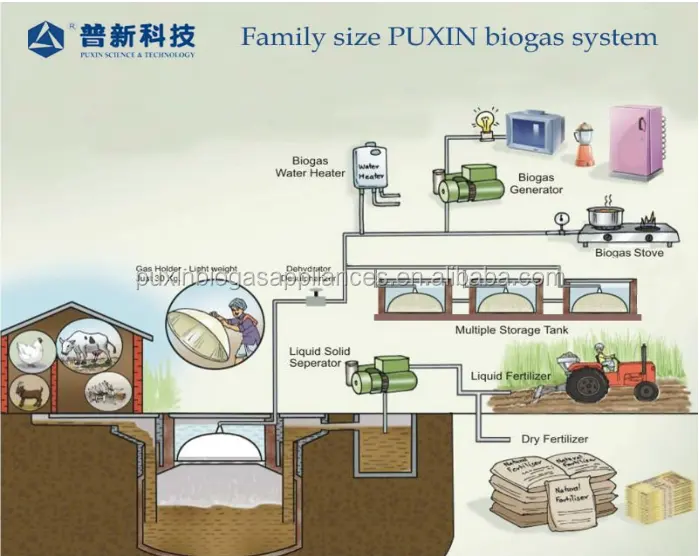

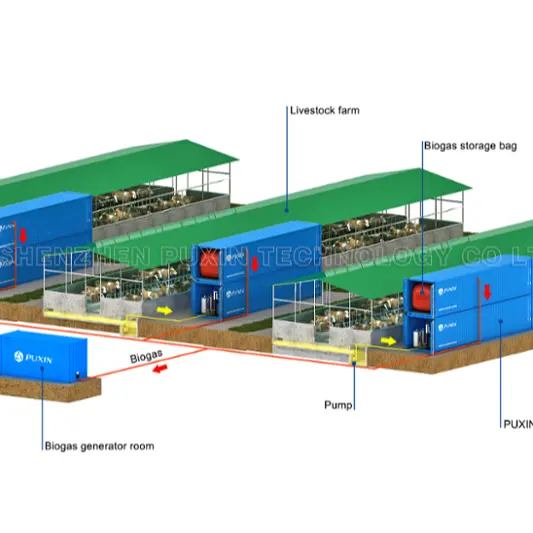

The slaughter waste water first pass through bar screen to remove big partials, next to the equalization tank to regulating of water quantity and quality; then, pumped into DAF, most of the slag and grease are removed in DAF, after that,wastewater entering into TEENWIN anaerobic plant, the macromolecular organic matter is broken down into small molecules of organic matter in anaerobic tank, anaerobic tank effluent entering into MBR plant, the organic matter is decomposed continue, most microorganisms and organic matter were intercepted in MBR plant, the water from MBR is clear, it can be reused after disinfection.

The died chicken and offals feed into shredder treated to powder then mixing with the chicken manure and slurry in pretreatment tank, and then pump into the anaerobic reactor, most organic matter digested in the reactor, this process produces biogas, after digested the slurry discharge into the slurry tank, the liquid supernatant of the slurry tank overflow to equalization tank mix with the wastewater for the slaughter house then pump into DAF to treat.

The biogas from the anaerobic plant can be collect, purify, storage as a clean energy can be used for electricity generation or water heating. The sludge is regularly dewatered by a solid-liquid separator, the solid can be used as a good bio-fertilizer

Why choose Teenwin animal cow chicken poultry slaughterhouse effluent wastewater offals manure treatment plant for abattoir:

1. Easy and quick installation: the plant is integrated device; it can be quickly put into use after installation

2. High efficient and Low energy consumption: it can be adjusted the optimum fermentation temperature according the different raw materials, and constant reacting temperature keeping, automatic PH adjustment and automatic mixing, biogas can be collect and transport to storage not need consume energy.

3. Environmental friendly: no odor and waste discharge, the gas produced is collected use for energy; the residue due to full fermentation has no smell, it is top bio-fertilizer, can be used for crop.

4. Faster gas production due to much higher and constant temperature, mixer in the reactor.

Contact message:

Tel: +86-15302648117

Whatsapp: +86-15302648117

Skype: Owenzhujie

QQ: 794144055

Wechat: Owenzhu2

Facebook: Owen Chu

Lead time: 10-25 working days for sample

Charge:The buyer pays the sample cost and freight.

Order Production :

Lead time: 10-35 working days after receipt of deposit.

Service and Advantage:

♦ Sales service time:24 hours for one day, 6 days for one week to supply completely service for you any time.

♦ Warranty time:12 months.

Delivery Service :

♦ Export standard , safety and environmental packing Quick lead time for mass production.

♦ Accept EXW, FOB, CIF and other price terms.

Payment Terms:

♦ T/T, Western Union, L/C, Money Gram.

Technical Service:

♦ Professional Engineering supplies technical supporting.

♦ Support OEM, ODM project.

Quality service:

♦ 100% quality testing for every finished products before delivery;