Светодиодный

- Категория: Теплоотводы >>>

- Поставщик: Dongguan,Xinqiang,Cooling,Technology,Co.,Ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 60.86 $* | 63.95 $* |

| Aug-15-2025 | 59.31 $* | 62.96 $* |

| Jul-15-2025 | 50.58 $* | 53.69 $* |

| Jun-15-2025 | 58.76 $* | 61.37 $* |

| May-15-2025 | 51.99 $* | 54.64 $* |

| Apr-15-2025 | 57.0 $* | 60.79 $* |

| Mar-15-2025 | 57.29 $* | 60.89 $* |

| Feb-15-2025 | 56.9 $* | 59.22 $* |

| Jan-15-2025 | 56.70 $* | 59.65 $* |

Характеристики

Company History

Dongguan Xinqiang Cooling Technology Co., LTD is a large industry & trade integrative company, established in 2008, located in Dongguan City, Guangdong Province, China, registered capital is 5 million RMB Yuan, modern factory covers 5,000 square meters,Total over 150 employees and more than 20 high level R&D engineers. As a famous industrial radiator manufacturer and supplier in china, Dongguan Xinqiang Cooling Technology Co., LTD has annual product capacity of 5,000,000 sets various kinds of industrial radiator and Heating element/Heating Appliance products etc, till now Dongguan Xinqiang Cooling Technology Co., LTD has developed and manufactured over 300 various kinds of industrial radiator products!

As one of the industry leader in all kinds of superconducting heat pipe radiators in china, Dongguan Xinqiang Cooling Technology Co., LTD has own independent design & development team, Company can develop and manufacture according to customers’ requirement and supply OEM products etc. Dongguan Xinqiang Cooling Technology Co., LTD could design and produce all kinds of superconducting heat pipe radiator, guide and manufacture super heat pipes fins, heat dissipation modules, cooling systems and son on. Dongguan Xinqiang Cooling Technology Co., LTD can manufacture various reflow soldering products of which are mainly used in computers, LED lamps, street lamp, refrigerators, various heat exchangers and so on. Company could supply OEM production according to customers’ requirements. Company has own international trademark "Xinqiang".

Dongguan Xinqiang Cooling Technology Co., LTD has heat pipe factory of which professional design and development of various heat pipes, Dongguan Xinqiang Cooling Technology Co., LTD also has another hardware factory of which include: product mold development department, Radiator profiles, relieving processing, CNC processing, stamping department, assembly department, computer gong processing department, welding department, Surface treatment, E-plated and anodizing etc.

Company adopt advanced modern management system and quality control system in all the production’s manufacturing and processing procedure, Company has passed through the "ISO9001 international quality system certification and "ISO14001 environmental management system certification". With modern equipment and processing line, assembling production line, and product test facility, all these technical and personal investment could guarantee our best competitive quality and service for customers.

Global Distribution Network

Through these years development, Company’s annual sales amount is over 10 million US Dollars in the world market, complete sales agent distribution and after-sales service network have been established in global market, the distribution and sales agency network are establishing in Asia, North America, South America, Europe, Australia and Africa, Dongguan Xinqiang Cooling Technology Co., LTD’s global distribution network is forming.

Sincerely welcome customers from the world to visit us and negotiate mutual long term business cooperation, our company could try our best to supply best quality products and best after sale service to support customers.

Product description

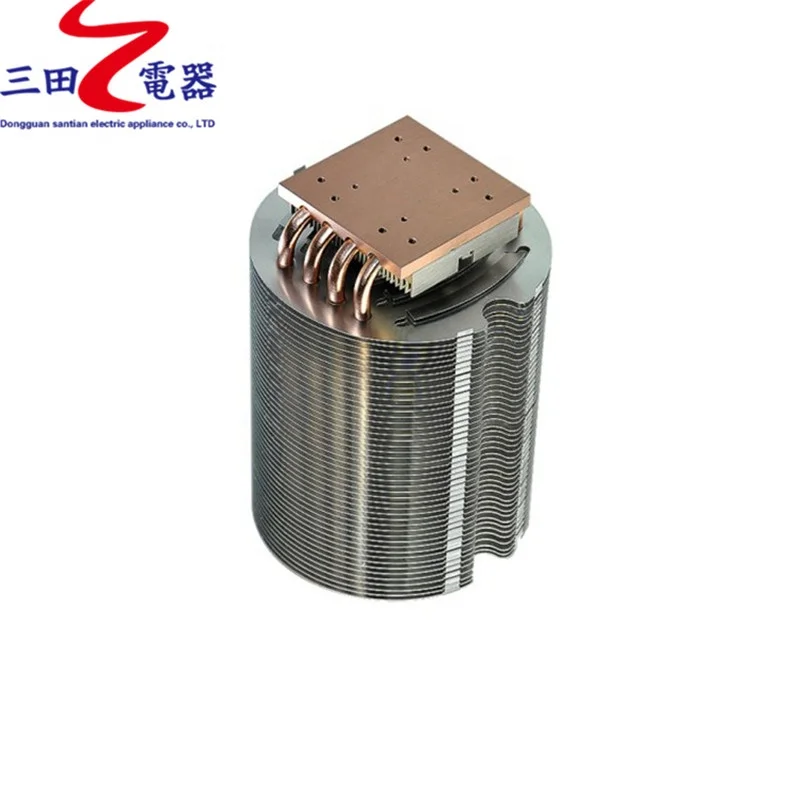

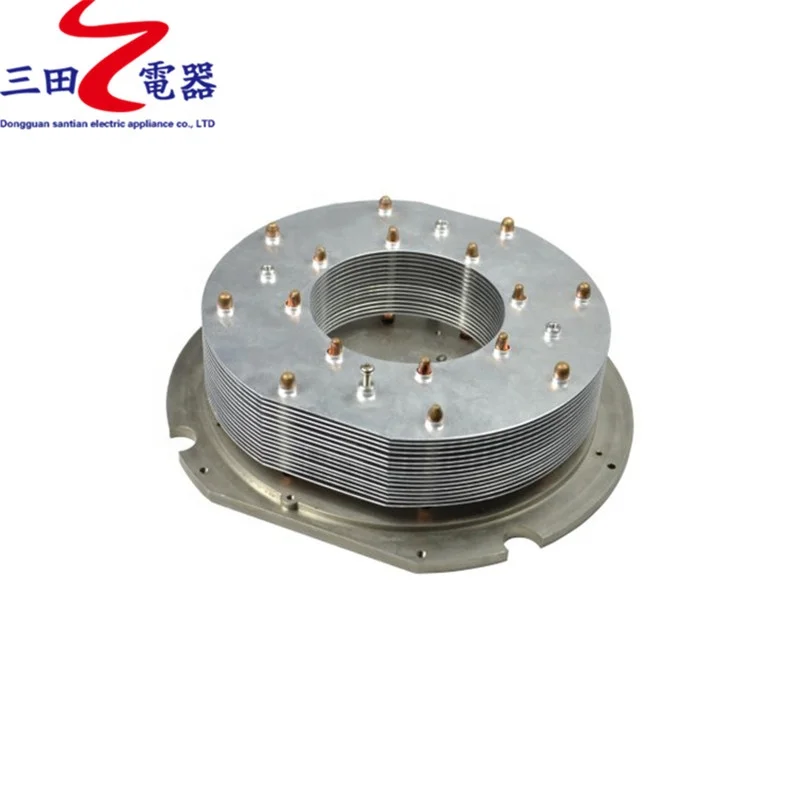

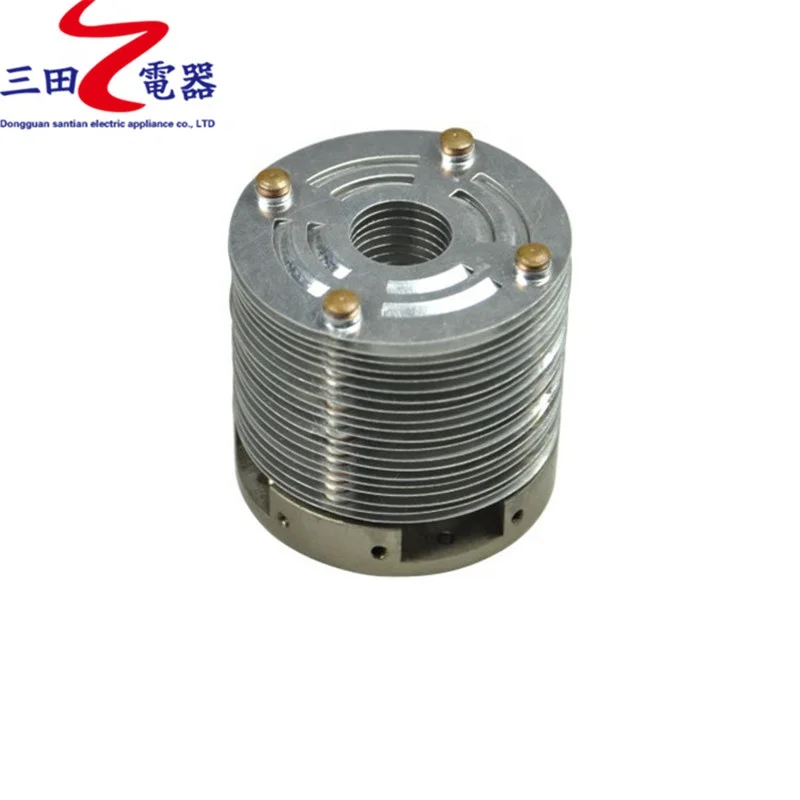

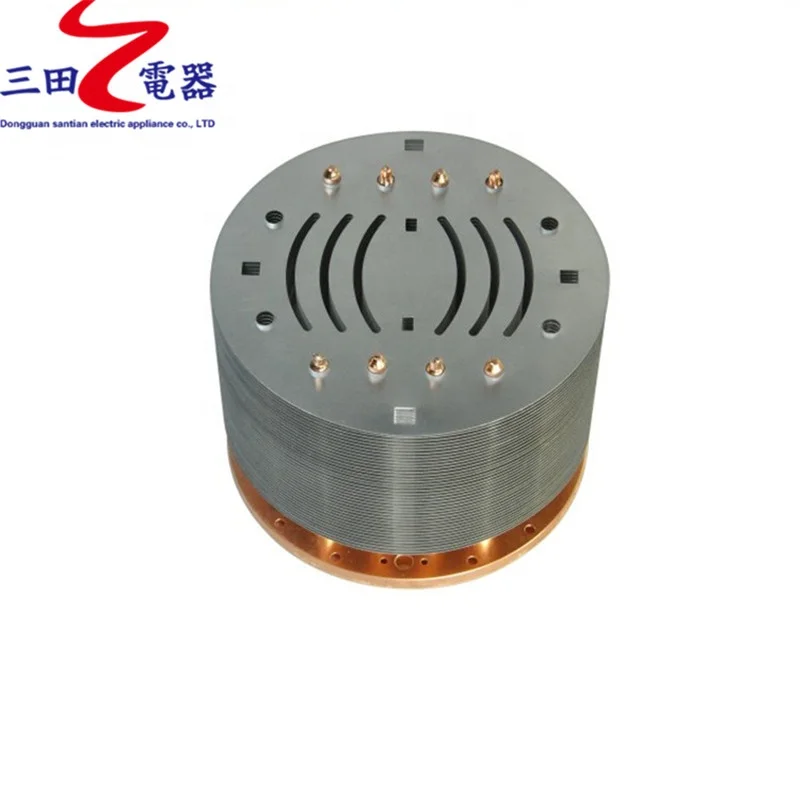

Material: Aluminum, stainless steel, brass, bronze, copper, copper heat tube

Processing: Die casting, Stamping, sheet metal fabrication, machining, riveting

Shape: Round, rectangular, square and son on

Size: As per drawing or samples or requirements

Surface treatment: Anodizing, plating and so on as per requirement

Application: LED heatsink aluminum heatsink for LED bulb

Service: ODM/OEM, customized made according to customers’ drawing or requirements.

Type: heat Sinks Surface Treatment: Polished Chrome

Warranty (year): 3 Process: Plating/welding/Wear fin

Certification:3C, CE, CQC,FCC, RoHS Place of Origin: Guangdong, China

Brand Name: Xinqiang Body Color: Silver

Shape: Square Body Material: Aluminum

Material: 6063 Aluminum Alloy Product Name: Heat Sink

Size: Can be customized Watt: add fan 800 Watts

Weight: 5kg Heatsink Material: Aluminum and copper

LED Light Source: 600W MOQ:10 Pcs

Supply Ability:

Supply Ability: 400000 Pcs per month

Manufacturing Process:

Stamping, deep drawing, bending, punching, laser cutting, threading, welding, tapping, riveting, grinding

Specification:

According to customer’s requirement

Thickness:

0.5mm—12mm, or other special available

Sample confirmation:

Before mass production, we will send the pre-production samples to customers for confirmation, We will modify the mould until customer satisfied

Product Scope:

All kinds of superconducting heat pipe radiator, guide and manufacture super heat pipes fins, heat dissipation modules, cooling systems and son on.

Various reflow soldering products of which are mainly used in computers, LED lamps, street lamp, refrigerators, various heat exchangers and so on. Company could supply OEM production according to customers’ requirements.

Others: Furniture hardware, electronic hardware, construction hardware, sheet metal processing, machinery parts, hydraulic fitting.

Packing:

according to customer’s requirements.

Products include:

metal stamping parts, metal press stamping parts, metal welding parts, metal drawing parts, metal punch parts, CNC metal Parts, CNC metal turning stainless steel parts, Metal chassis, metal cabinet, metallic machinery casing, Metal enclosures, metal boxes, metallic machinery casing, metallic communication products, metallic auto parts, metallic refrigerator parts, metallic washing machine parts, wending machine shell fabrication, communication, communication cabinet fabrication, mold designing making and so on, OEM progressive metal stamping parts.

Material available:

Carbon steel (CRS/SPCC/SECC, etc,), stainless steel, spring steel, bronze (beryllium, phosphor, etc), brass, copper alloy, aluminum alloy, tinplate, nickel silver, plastic

Surface treatment available: zinc/nickel/chrome/tin plating ) color or natural). Galvanization, anodizing, oil spraying, powder coating, polishing, passive, brush, wire drawing etc.

Metal processing available:

Stamping parts: tooling making, sample approval, cutting, stamping, punching tapping, welding, bending and forming, finishing, assembly. CNC Parts: CNC lathe milling, CNC lathe turning, drilling, tapping, finishing, assembly, packing

Product Capacity:

5,000,000 sets

Product Flow:

CNC machining: CNC machining led aluminum and copper

Stamping Processing: Heat dissipation fin press, all kinds of metal stamping

Welding heat dissipation fin: Assembled by reflow soldering heat dissipation fin radiator

Assembly process: Assemble the radiator

Testing process: Test the power

Production Facility:

Production Equipment:

Equipment Name | Type | Total (Sets) |

CNC | XK640 | 22 |

Stamping Equipment | 40T, 60T | 9 |

Hydraulic Equipment | 200T, 120T, 100T, 80T, 65T, 50T, 10T | 15 |

Contract Manufacturing: OEM Service Offered Design Service Offered Buyer Label Offered

Factory Information:

OEM service offered, Design Service Offered, Buyer Label Offered

Factory Size: 6000 square meters

Location: No.5 Weiling Road Xin Village South Tangxia Town Dongguan city, Guangdong province, China

Number of production line: 4

Contract Manufacturing: OEM service offered, design service, offered buyer label offed

Annual output value: US$200 million to US$500 million

Annual production Capacity:

Product Name | Average produced | Max produced | Unit Type |

Heat pipe | 20,000,000 | 30,000,000 | Pcs |

Heat sink | 2,000,000 | 6,000,000 | Sets |

CNC machining | 10,000,000 | 20,000,000 | Sets |

Shovel tooth radiator | 1,000,000 | 2,000,000 | Sets |

Extruded aluminum profiles | 3000 | 5000 | Tons |

Production Line

Production Line | Supervisor | No of operators | No of in Line QC/QA |

Backflow welding furnace | 5 | 20 | 5 |

Assembly line | 5 | 15 | 5 |

Product Flow:

CNC machining: CNC machining led aluminum and copper

Stamping Processing: Heat dissipation fin press, all kinds of metal stamping

Welding heat dissipation fin: Assembled by reflow soldering heat dissipation fin radiator

Assembly process: Assemble the radiator

Testing process: Test the power

Quality Control Procedure:

CNC Machining quality management,

Precision Stamping quality management,

Anodizing quality management,

QA inspection facility quality management,

Inspectors check at the assembly line,

High quality inspection instruments: Insize three point digimatic international micrometer, High performance 2D Measurement system,