CGSZ2016-12 Customized intelligent Glass Double Edger Machines Exported To Worldwide Manufacturing

- Категория: Машина по производству стекла >>>

- Поставщик: Cgtech,Glass,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.38 $* | 0.58 $* |

| Aug-16-2025 | 0.36 $* | 0.83 $* |

| Jul-16-2025 | 0.80 $* | 0.19 $* |

| Jun-16-2025 | 0.93 $* | 0.17 $* |

| May-16-2025 | 0.62 $* | 0.29 $* |

| Apr-16-2025 | 0.57 $* | 0.27 $* |

| Mar-16-2025 | 0.53 $* | 0.24 $* |

| Feb-16-2025 | 0.4 $* | 0.40 $* |

| Jan-16-2025 | 0.20 $* | 0.94 $* |

Характеристики

Products Description

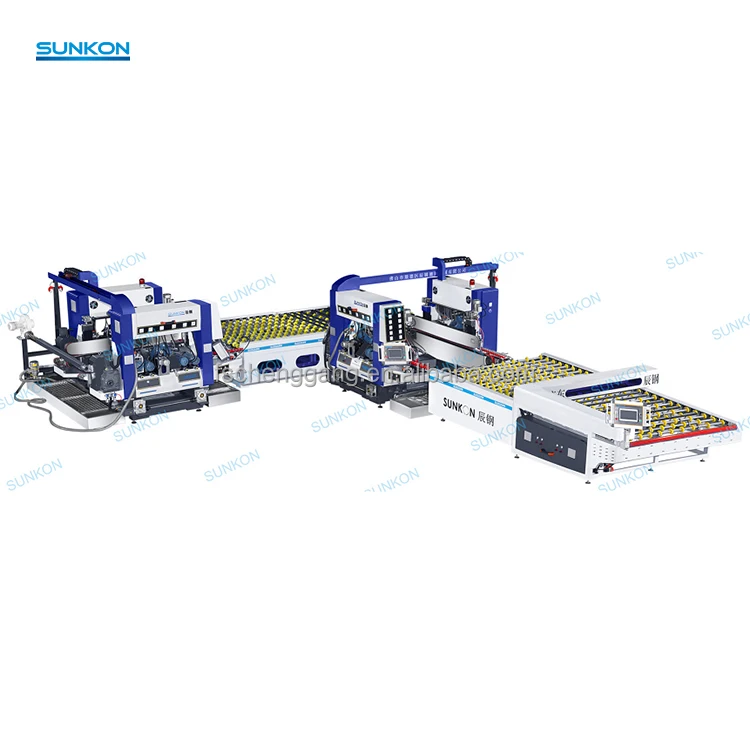

■ CGSZ2016-12 Glass Straight Line Double Edging production line is grouped with 2 double edging machines, 1 turning table. It is economic,efficient, practical and reliable, which is researched & developed independently by Sunkon company. Suitable for construction andother type of flat glass processing

■ Installed with excellent linear guide and screw mandrels which ensures the processing

precision. Bracket of movable side system is W frame design, which increases the accuracy of movements and the degree of stability; also it can extend the life time of the linear rack

■ All-in-one structure for machine and circuit box is good for waterproof, space saving and convenient for operation.

■ Position corrected device has been added on the machine, which solves the deviate problem of small glass, and truly realize intelligent operation of connected machines when transferring glass.

■ Siemens PLC control with touch screen, the data setting and the grinding status of glass can be showed on the controlling center. Processing width, thickness, and lifting of upper arris are adjusted automatically. Totally 12 spindles, 6 spindles per side.

■ Installed with excellent linear guide and screw mandrels which ensures the processing

precision. Bracket of movable side system is W frame design, which increases the accuracy of movements and the degree of stability; also it can extend the life time of the linear rack

■ All-in-one structure for machine and circuit box is good for waterproof, space saving and convenient for operation.

■ Position corrected device has been added on the machine, which solves the deviate problem of small glass, and truly realize intelligent operation of connected machines when transferring glass.

■ Siemens PLC control with touch screen, the data setting and the grinding status of glass can be showed on the controlling center. Processing width, thickness, and lifting of upper arris are adjusted automatically. Totally 12 spindles, 6 spindles per side.

Max. arris grinding | 3mm |

Process speed | 1~8 m/min |

Glass thickness | 3~19 mm |

working height | 920mm |

Voltage/frequency | 380V/50HZ or customized |

Total power | 150kw |

Max. processed size | 2000*1600mm |

Min. processed size | 350*350 mm |

Details Images

Main base structure

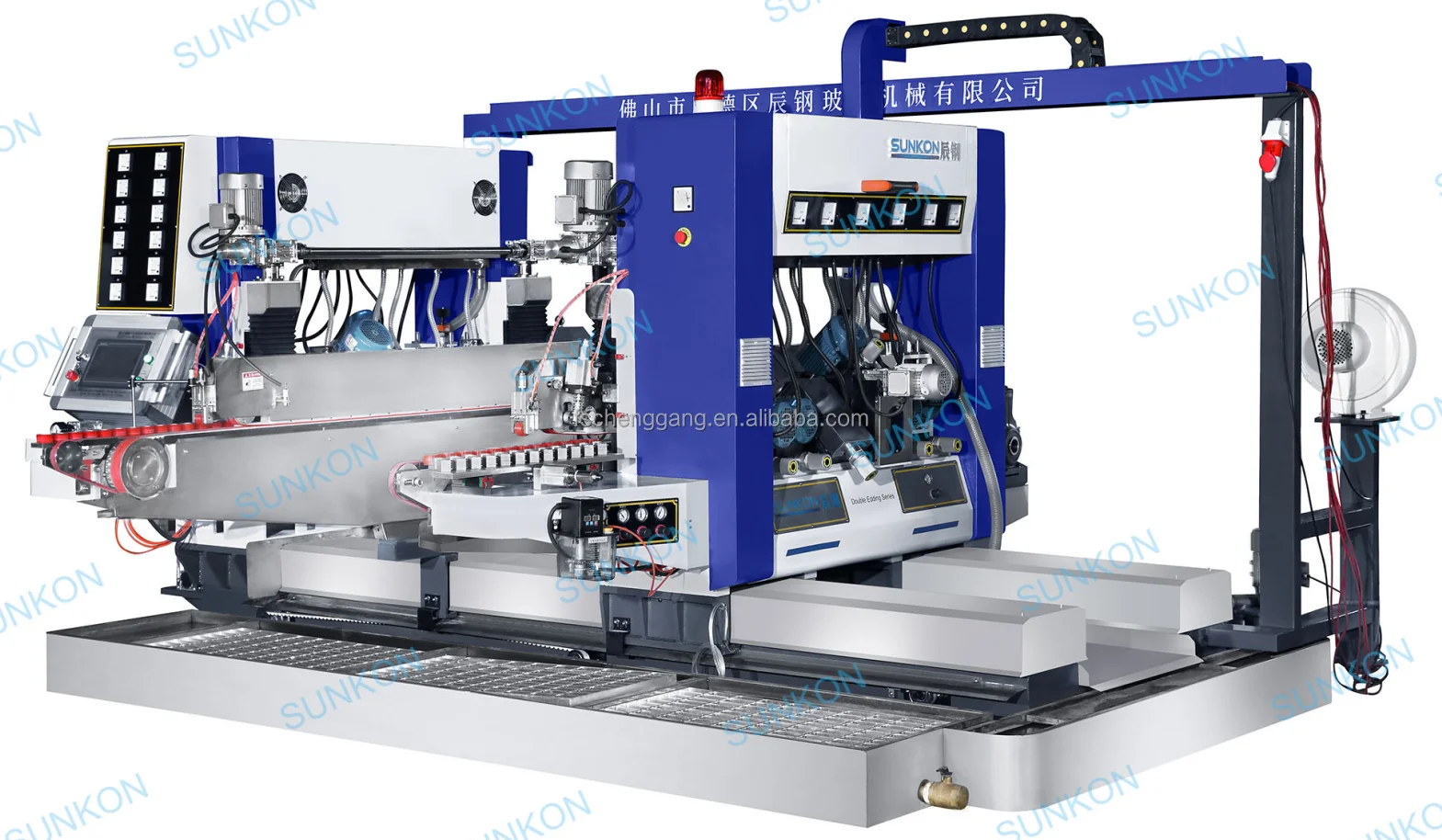

Machine base is made of welding square tube with 12mm thickness. It was formed in one piece and not deformed

The machine automatically lubricates and maintains the main components through the automatic oil injection system in all directions.

Middle support rack

The automatic support rod can move with the movement of the mobile end of the edge grinding machine, and is always in the middle position to support the glass, preventing the glass from sinking in the middle position due to gravity, and the two ends are tilted, which affects the processing quality.

Frequency inverter with mandrel screw, Two big gears to make sure strong conveying.The synchronization of transmission is higher and the accuracy is more accurate.

The conveyor beam guide groove is an exclusive formula is using ultra-high polymer materials. It has the characteristics of wear resistance, aging resistance, small deformation, etc., and the addition of graphite material makes the friction of the timing belt less when running

The W-shaped frame design improves the accuracy and stability of the movement and prolongs the service life

Air knife with blower to blow water on glass surface after processing, blow water into water tank.

Our Case

Product packaging

Company Profile

Why Choose Us

Product Catalog

FAQ

Похожие товары

Машина для ламинирования стекла EVA PVB

US $9000-$12000

Hot Sale Automatic Mobile Tempered Glass Cutting Machine

US $2300-$2500

Горизонтальная стеклянная стиральная машина 1600 мм

US $2300-$8000

Пескоструйная машина для стекла и дерева

US $9000-$12000