Цементная клинкерная шлифовальная производственная

- Категория: Mining Machinery >>>

- Поставщик: Henan,Zhengzhou,Mining,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.27 $* | 0.46 $* |

| Aug-17-2025 | 0.18 $* | 0.51 $* |

| Jul-17-2025 | 0.91 $* | 0.28 $* |

| Jun-17-2025 | 0.36 $* | 0.58 $* |

| May-17-2025 | 0.89 $* | 0.13 $* |

| Apr-17-2025 | 0.12 $* | 0.7 $* |

| Mar-17-2025 | 0.40 $* | 0.37 $* |

| Feb-17-2025 | 0.19 $* | 0.13 $* |

| Jan-17-2025 | 0.66 $* | 0.12 $* |

Характеристики

Complete Cement Clinker Grinding Production Line Price

Brief Introduction of Grinding Ball Mill

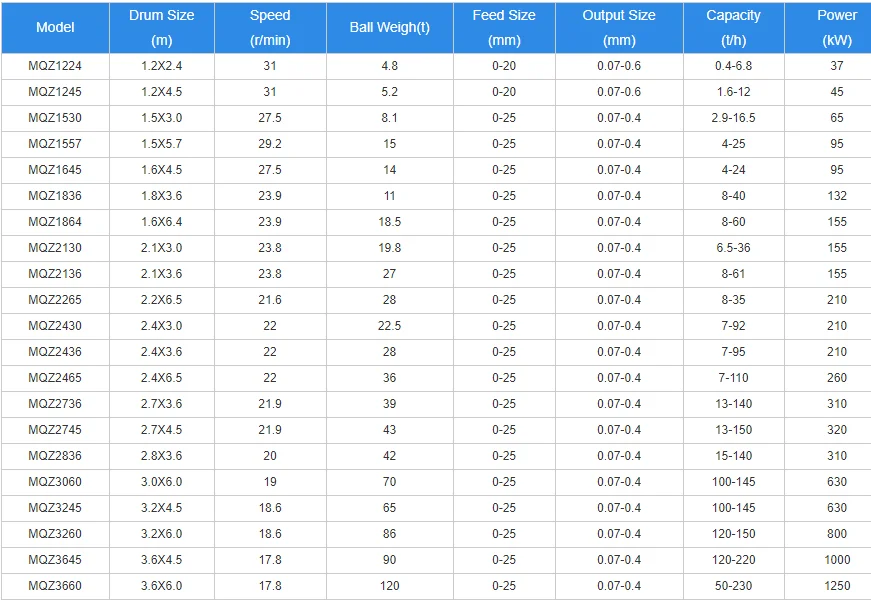

Ball mill is mainly used for grinding in mining (metallic minerals and non-metallic minerals), cement, refractories, chemical, power plant, aluminum ,building material, glass, ceramic, steel slag and fly ash, ect. It follows more crushing and less grinding principle to save energy. The feed size to ball mill shall be smaller than 25mm, the output size can be adjusted by revising steel balls ratio.

Working Principle of Grinding Ball Mill

A cylinder with small diameter and large length is the key parts for wet grate ball mills. It rotates slowly driven by the transmission equipment. Materials are fed into the cylinder from the feeding inlet and smashed by the falling impact and autogenous grinding of steel balls and ores. Due to constant feeding, the pressure propels qualified products to be discharged from the discharging outlet.

Grates are installed in the outlet to compel slurry to discharge, reduce over-grinding and stop discharging steel balls. Among the same production conditions, it has higher production capability.

1. Large capacity and continuous work are obvious advantages;

2. Various barrel lining and grinding media, excellent corrosion resistance;

3. Large capacity and crushing ratio; High grinding efficiency, low energy consumption;

4. Large application range, simple structure and convenient maintence;

5. Good sealing performance. It can be adapted to different working conditions;

6. Product fineness is adjustable, uniform and high qualified.

7. Installation and adjustment are very convenient and easy to operate.

Offer Professional Engineet to provide Technical Support

About Us

Henan Zhengzhou Mining Machinery Co., Ltd (ZK) was found in 1956. After half century development, it becomes a comprehensive modernized enterprise, including the business service such as scientific research, design, develop, manufacture, sales, installation, test and training. The main products of company include: ball mill, rotary kiln, vertical pre-heater, cooler, crusher, metallurgical coke oven, magnetic separator, flotation machine, classifier, feeder, bucket elevator, pre-heater, dust collector, elevator, drier, and other equipments

Over 60 Years Mining Equipment Manufacturing Experience

Pre-sale services

Act as a good adviser and assistant of you; enable you to get rich and generous returns on your investments;

1. Select equipment model;

2. Design and manufacture products according to clients' special requirement;

3. Train technical personnel for clients

After-sales service

Provide considerate services to minimize your worries.

1. Assist you to prepare for the first construction scheme;

2. Install and debug the equipment;

3. Train the first-line operators on site;

4. Examine the equipment regularly;

5. Take initiative to eliminate the troubles rapidly at site;

6. Distribute the guarantee fittings door-to-door;

7. Provide perfect service;

8. Provide technical exchanging;

9. Provide maintenance for big items.

Now, please click the following contact to send us email !

↓↓↓