Медовый пресс фильтровальная машина микрогидравлический масляный

- Категория: Фильтр-прессовое оборудование >>>

- Поставщик: Wenzhou,Qiangzhong,Machinery,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.21 $* | 0.12 $* |

| Aug-15-2025 | 0.84 $* | 0.66 $* |

| Jul-15-2025 | 0.65 $* | 0.55 $* |

| Jun-15-2025 | 0.99 $* | 0.1 $* |

| May-15-2025 | 0.40 $* | 0.95 $* |

| Apr-15-2025 | 0.15 $* | 0.51 $* |

| Mar-15-2025 | 0.22 $* | 0.39 $* |

| Feb-15-2025 | 0.33 $* | 0.6 $* |

| Jan-15-2025 | 0.24 $* | 0.37 $* |

Характеристики

Products Description

Features

The frame filter is suitable for industries such as biological products, medicine, brewing, food and beverage, tobacco, water treatment, petrochemical, environmental protection, etc., for precision filtration, clarification sterilization, purification treatment, etc. It can also filter the injection, infusion and other liquids in the pharmaceutical industry with good performance. The filter can also filter by means of a filter layer formed by a primary filter layer or a filter aid (for example, diatomaceous earth, clay, activated carbon, etc.) to obtain a clean liquid. According to the different filtration accuracy (crude filtration, fine filtration) requirements of the filtrate, customers can choose different filter materials for different filtration precision; and increase or decrease the number of layers of filter plates according to the production volume.

The filter has the advantages of less filtrate loss, large circulation, simple operation, convenient disassembly and assembly, and easy cleaning. The filter plate adopts a special structure of a flat threaded mesh shape, which is smooth and flat, and the filter material (filter cloth, filter paper, filter membrane) is not easily damaged, and can effectively prolong the service life of various filter materials, thereby reducing the production cost. The filter is equipped with a stainless steel pump, which has low motor power and low power consumption. The rubber wheel is mounted under the frame for flexible movement and light weight.

The filter has the advantages of less filtrate loss, large circulation, simple operation, convenient disassembly and assembly, and easy cleaning. The filter plate adopts a special structure of a flat threaded mesh shape, which is smooth and flat, and the filter material (filter cloth, filter paper, filter membrane) is not easily damaged, and can effectively prolong the service life of various filter materials, thereby reducing the production cost. The filter is equipped with a stainless steel pump, which has low motor power and low power consumption. The rubber wheel is mounted under the frame for flexible movement and light weight.

Product Parameters

Structure

Four corners of each filter plate of the frame filter have four liquid-passing corner holes, and only the two vertical corner holes are communicated with the inside, and the filter plate and the filter frame are alternately arranged (the filter plate is double-sided hole plate, filter frame is non-porous plate). During filtration, media is fed through two liquid-passage holes on one side of the filter frame. After passing through the filter layer (filter media), the clear liquid is discharged from the two liquid outlet corner holes on the filter plate side.

Working Principle

This machine is a stainless steel multilayer frame filter press. It is suitable for the closed filtration of liquids with a concentration less than 50%, low viscosity, and low slag content to achieve the effects of fine filtration, decarbonization, and semi-fine filtration. It uses microporous membranes directly for sterile filtration. This machine has a large filtration area, large flow, and a wide range of applications, so it is widely used in pharmaceutical, chemical, food and other industries, especially for pharmaceutical injections, liquid filtration, the effect is very good.

The design idea of the plate-type filter was inspired by the cardboard filter, and this filter is fine manufactured after innovation and improvement. The product has a novel appearance and practicality. It can fit various kinds of filter materials such as filter cloth, filter paper board, filter film, etc. It can meet the requirements of different precision, grades and filtration processes of many kinds of liquids.

Two inlet and outlet connecting pipes are used for the inlet and outlet ports, which greatly increase the flow rate and ensure that it is pressed evenly during operation. Two glass sights can visually observe the difference of liquids between pre-filtration and post-filtration; the pressure gauge above the feed inlet clearly shows the state of working pressure during filtration; the sampling valve above the discharge port can not only facilitate the sampling of liquid material after filtration, but also can be used to perform deflation and emptying operation at the time of turning on and shutting down the filter. but also can be used for deflation and discharge when turning on and turning off the machine. The tri-clamp connector is very convenient for installation and removal. The matching valve and fittings conform to ISO and other health standards and they are exquisitely manufactured and can be integrated with the pipelines in the workshop.

The design idea of the plate-type filter was inspired by the cardboard filter, and this filter is fine manufactured after innovation and improvement. The product has a novel appearance and practicality. It can fit various kinds of filter materials such as filter cloth, filter paper board, filter film, etc. It can meet the requirements of different precision, grades and filtration processes of many kinds of liquids.

Two inlet and outlet connecting pipes are used for the inlet and outlet ports, which greatly increase the flow rate and ensure that it is pressed evenly during operation. Two glass sights can visually observe the difference of liquids between pre-filtration and post-filtration; the pressure gauge above the feed inlet clearly shows the state of working pressure during filtration; the sampling valve above the discharge port can not only facilitate the sampling of liquid material after filtration, but also can be used to perform deflation and emptying operation at the time of turning on and shutting down the filter. but also can be used for deflation and discharge when turning on and turning off the machine. The tri-clamp connector is very convenient for installation and removal. The matching valve and fittings conform to ISO and other health standards and they are exquisitely manufactured and can be integrated with the pipelines in the workshop.

Film filter:

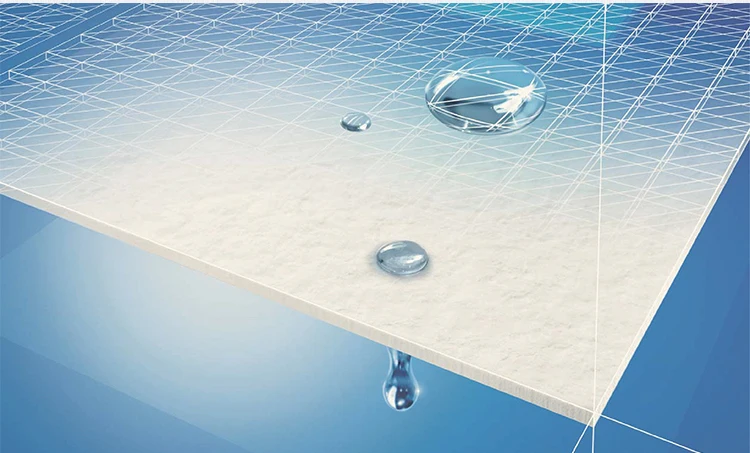

The film filter material made of mixed fibers meets the quality standards, and its product surface is smooth, light and thin, with high porosity and uniform pore structure, so it has the characteristics of high flow velocity and low adsorption.

This product is suitable for the pharmaceutical industry, biological products, electronics industry, brewing, watches and other industries, and it can filter medical oil, lubrication oil, fuel oil, etc., filter bacteria and particles. It is also used for scientific research experiments, laboratory, etc. Generally it can remove 0.65um particles, bacteria below 0.45um.

Instructions for use:

● Place the filter membrane in a clean container and soak it in distilled water of about 70°C. After soaking it for about 4 hours, rinse it with distilled water of appropriate temperature before use.

● Put the cleaned filter (wet) into a suitable filter to prevent leakage from the surroundings. Put the filtrate from the inlet and discharge the air at the exhaust port, then the machine could work for filtration.

Polypropylene (PP) filter instructions for use:PP filter membrane is made of polymer material, non-toxic, widely used in medicine, chemical industry, food, beverage, alcohol and other fields.

The PP filter membrane can withstand high temperatures up to 121°C. 30 minutes hot pressure disinfection, working temperature below 100 °C.The PP filter membrane has a good strength, no deformation, no media fall off, no re-contamination.First use 70% ethanol to infiltrate the filter for several minutes.PP filter membrane adapt depth filtration, resistance is small, fast flow. It is especially suitable for position difference filtering, such as achieving higher flow in low dropout conditions and long service life.

The film filter material made of mixed fibers meets the quality standards, and its product surface is smooth, light and thin, with high porosity and uniform pore structure, so it has the characteristics of high flow velocity and low adsorption.

This product is suitable for the pharmaceutical industry, biological products, electronics industry, brewing, watches and other industries, and it can filter medical oil, lubrication oil, fuel oil, etc., filter bacteria and particles. It is also used for scientific research experiments, laboratory, etc. Generally it can remove 0.65um particles, bacteria below 0.45um.

Instructions for use:

● Place the filter membrane in a clean container and soak it in distilled water of about 70°C. After soaking it for about 4 hours, rinse it with distilled water of appropriate temperature before use.

● Put the cleaned filter (wet) into a suitable filter to prevent leakage from the surroundings. Put the filtrate from the inlet and discharge the air at the exhaust port, then the machine could work for filtration.

Polypropylene (PP) filter instructions for use:PP filter membrane is made of polymer material, non-toxic, widely used in medicine, chemical industry, food, beverage, alcohol and other fields.

The PP filter membrane can withstand high temperatures up to 121°C. 30 minutes hot pressure disinfection, working temperature below 100 °C.The PP filter membrane has a good strength, no deformation, no media fall off, no re-contamination.First use 70% ethanol to infiltrate the filter for several minutes.PP filter membrane adapt depth filtration, resistance is small, fast flow. It is especially suitable for position difference filtering, such as achieving higher flow in low dropout conditions and long service life.

Product details

Product Paramenters

Advantages

Certification | 25 National Patents, Audited by SGS/TUV/CE/ISO9001 |

Quality Guarantee | Complaint rate as low as 5‰ for 15 years. If you decide to purchase from us, any malfunction happened, once you enquiry us, we will reply you solution within 48 hours except the special reasons |

Short Lead Time | Lead time is flexible. Short turnaround of replacement parts made by substantial storage, Normally we are 20% faster than others. If you have urgent orders, pls feel free to contact us. We will get the job done with 100% satisfaction. |

24/7 Available | All your inquiry will be responded within 1 hour. All your quotation will be satisfied within 12 hours. |

Why choose us? | •100% manufacturer • Rich production experience •Strict Quality Control System •Flexible MOQ •Punctual delivery •Excellent and Experienced Team |

Company Profile

Wenzhou Qiangzhong Machinery Technology Co., Ltd. is a professional manufacturer of processing machines, located in Wenzhou City, China, near Longwan International Airport. Our main products include the high shear mixer, mixing tank, colloid mill, sanitary pump, sanitary filter, sanitary pipe, and valve. They are widely used in industries such as brewery, dairy product, beverage, chemicals, cosmetics, pharmaceuticals, and biopharmaceuticals.

We offer complete sets of service from research and development, production, sales, after -sales to maintenance, in accord with GMP, QS, and HACCP. As a pioneer and innovator, Obtain 25 National Patents, Audited by SGS / TUV / CE / ISO9001.

Thanks to advanced technologies and production equipment, strict meeting industry standards, our quality is well-developed continuously. So far, our products have been sold not only all around China but also globally, such as Europe, America, Australia, Southeast Asia, Middle East, etc.

Packaging & Shipping

Strict packing process to ensure the safety and completeness of the goods

We are experienced in the whole packing and shipping process, and we will be responsible for any damage made during shipping and send clients replacements for free.

* Sufficient inner protection with different materials, including bubble bag, foam board and others.

* Qualified wooden package or carton for different products or as customer require.

* Sufficient inner protection with different materials, including bubble bag, foam board and others.

* Qualified wooden package or carton for different products or as customer require.

Похожие товары

Фильтрующая пресс-машина для очистки сточных вод с чернилами

US $6500-$7000

Фильтрующий пресс используется для очистки сточных вод бетономешалки

US $35000-$112000