Горячая Распродажа Индукционная формовочная машина для сжимания на

- Категория: >>>

- Поставщик: Shenzhen,Dongda,Industrial,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 793.8 $* | 833.34 $* |

| Aug-16-2025 | 786.83 $* | 825.92 $* |

| Jul-16-2025 | 659.7 $* | 692.35 $* |

| Jun-16-2025 | 773.67 $* | 812.28 $* |

| May-16-2025 | 673.44 $* | 707.20 $* |

| Apr-16-2025 | 759.58 $* | 797.89 $* |

| Mar-16-2025 | 753.28 $* | 791.67 $* |

| Feb-16-2025 | 746.95 $* | 783.42 $* |

| Jan-16-2025 | 739.30 $* | 776.48 $* |

Характеристики

hot selling blacksmith induction forge machine for sale

model | DDZP-110 | ||||

maximum voltage scope | 110kw | ||||

input voltage scope | 70-550V | ||||

output oscillating frequency | 1-20KHZ based on customer requirement | ||||

input voltage frequency | three phase 380V±20% 50-60HZ | ||||

heating,retain current | 100% 24H | ||||

Weight (kg) | 85 | ||||

volume L*W*H (cm) | 81*43*90 | ||||

Forging furnace | |||||

models | max input power/kw | heating capacity | |||

iron,ss to 1100℃ | copper to700℃ | ||||

DDZP-110 | 110 | 4.5Kg/min | 6.5Kg/min | ||

Melting furnace | |||||

models | max input power/kw | capacity each time | |||

ferrous metal | aluminum | copper gold silver bronze | |||

DDZP-110 | 110 | 60kg | 50kg | 150kg | |

the induction heating machine will be placed in the forging table. size of the customized forging table is depends on the heating material.

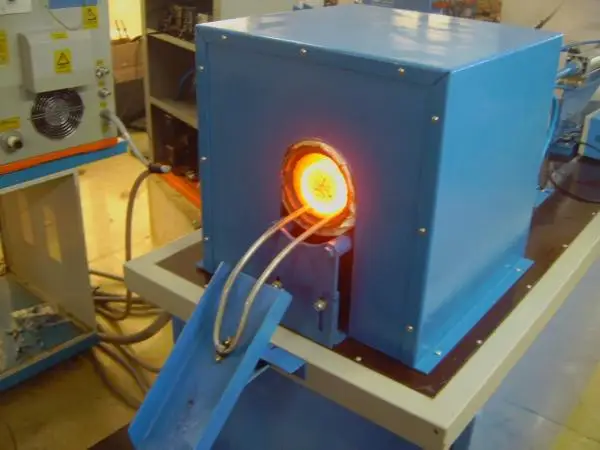

MACHINE DESCRIPTION:

These machines using important excellent IGBT frequency module and our company’s third generation current conversion control technology, which is double controlling current conversion technology. The power and frequency can be adjust separately,as using IGBT soft switching device and amorphous inductor to form high frequency chopper circuit to adjust the power,IGBT series resonance and frequency auto adjustable technology can have more accurate soft control inverter process, all these can guarantee the induction heater can work more reliable with high power with 100% duty. Compare to second generation frequency conversion technology, the third generation is more suitable to use in high power heater to show its reliability.

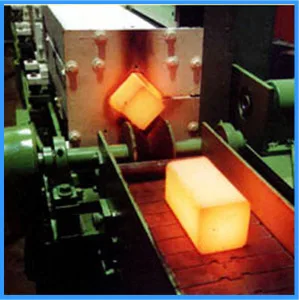

GOOD PERFORMANCE ON FORGING:

Can be used in equal or large than Φ12mm steel, stainless steel, copper, brass, aluminium etc round and square metal material or other shaped blank material continuous total heating.

Large range of frequency, from 1khz to 20khz. The frequency will be adjust according to material size and heating depth.

The medium frequency induction forging furnace ‘s coil can be 500mm to 1.8m, can heat single or couple of materials to total heat.

When continuous heating, the coil’s load is balanced so when single material load is from room temperature to 1100C°in heating the loading’s change will change heater’s actual heating power. In whole continuous heating process, induction heater can maintain 85% of the rated power and the induction heater can be used more efficiently.

When heating copper brass and aluminium etc non ferrous metal, within reasonable designed capacitor and coil, the exact power can reach to 85% of the maximum power. When heating copper brass, the heating capacity can 3.5kg/kw in one hour.

The machine have constant current and constant frequency control function, it can improve heating efficiency to save more energy.

Easy assembling.the machine connecting cable all have marks to clarify also have files and video for assembling. It just need to connect power and water for chilling can finish the assembling, only takes couple of minutes. No need professional assembling engineer,client can save more time ,energy and cost.

Easy to operate. Heating current and heat preservation function can adjust separately. Provide video guiding for whole operation.

The machine have timer function. The heating speed(heating time) and heat preservation time can be digitally set up.

The machine has fault analyzing and alarm system. When over pressure, over flow, over temperature,water fail etc fault happened, the process will protect main components in a regular time. The machine can have fault alarm light, easy for client to detect when fault happened.

100% full load, can continuously working 24 hours.

Frequency auto tracing and adjust system, no need to adjust frequency frequently adjust when working.

Compact size. To meet the requirements for factory production , school teaching and laboratory use.

Energy saving. In full power range, have very high power factor and power source efficiency.compare to silicone carbide medium frequency, can save more than 20% energy.

Welding

1.Standard parts, fastener parts heating.

2.drill steel , drill tool are tempering,forging, extrusion , etc.

3.Diamond saw blades,rill tools'welding.

4.Drill bit,coal drill bit,pick bit's welding.

5.Braze lathe tool,milling cutter and all kinds of wooden cutter, braze high speed steel saw blades.

Hardening

1.Hardening parts of automobile,motorbike,mold,agricultural machinery.

2.Hardening machinery parts,such as: all kinds of gear wheel,chain wheel,kinds of axis,pin.

3.Hardening the industrial of machine tool,such as:bed guide way of machine tool.

4.Heat treatment pilers,spnner,screwdriver,drill,axe.

5.Hardening pin,piston ring ,spring pin,valve, shifting fork.

6.All kinds of track spiker.

Forging

Forging dies, open die forging equipment: extrusion, rotational moulding, cut off, bendingtorsion shaping

equipment: machinery press, automatic forging press, hydraulic press, shaping equipment, forging hammer,

forging machine, cut machine, bend correction machine, riveting machine, forging use industrial furnace and

energy conservation technology, forging mold and repair technology equipment.

- established in year of 1996.

- 12 technical engineers.

- 10 consulters after sales team.

- 1250 square warehouse.

CUSTOMER VISIT & EXHIBITION

QUALITY CHECKING

COMPONENT TEST IQC CHECKING AGING

OUR SERVICE

- application testing and evaluation: offers application development services and application testing services by induction machines with wide range of frequencies and powers. we can evaluate if your application will benefit from induction heating.

- application optimization service: offers expertise induction heating solution guide to optimize your heating process under your equipment

- custom design and manufactorur: we design and manufacture induction machine for a wide range of induction applications and customer's requirment. including color language

- installation commission: the manual with photo and video make installation easy, on line& on-site technical service is also available

- maintenance: provide online and on site technical assistance for preventive and corrective maintainance

- repair& spare part: quick feedback to customer's repair and spare parts(within 8hours), trouble shooting guide with photo&video and online engineer servicehelp you repair machines easily.

Component Supplier(IGBT, MOSFET, AND OTHERS)

- How do i know which machine is suitable for my heating application?:please talk to our sales, they will tell you which machine is best for your heating requirement.

- I already know which power and frequency machine is best for us, can you quote us?

:yes. and please send some of your workpiece drawing and pictures. the finished machine have coils, this is custom made according to workpiece size. - Do you provide heating solution?

:yes. we will provide solution based on your heating requirements. the confirmed solution is based on exact testing on your real workpiece. - What is the lead time?

:we always have heater in stotage. customized heater 's leading time is depends. - Besides from the induction heater, do we need another accesory machines?

:yes. every induction heater need water cooling. other accesories is required according to exact project. - Can you accept customized order?

:yes. - What is the after sales services?

:each machine have 1year warranty. oversea services is provided. we have after sales agent in India, Russia, North America and South America.