Небольшие идеи для бизнеса водонепроницаемая Автоматическая декоративная производственная линия MGO

- Категория: Огнестойкие материалы >>>

- Поставщик: Hebei,Lvjoe,Machinery,Manufacturing,Group,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.77 $* | 0.96 $* |

| Aug-15-2025 | 0.62 $* | 0.1 $* |

| Jul-15-2025 | 0.80 $* | 0.48 $* |

| Jun-15-2025 | 0.8 $* | 0.36 $* |

| May-15-2025 | 0.65 $* | 0.71 $* |

| Apr-15-2025 | 0.42 $* | 0.49 $* |

| Mar-15-2025 | 0.9 $* | 0.39 $* |

| Feb-15-2025 | 0.57 $* | 0.59 $* |

| Jan-15-2025 | 0.56 $* | 0.34 $* |

Характеристики

Small Business Ideas Waterproof Automatic Decorative MGO Board Production Line

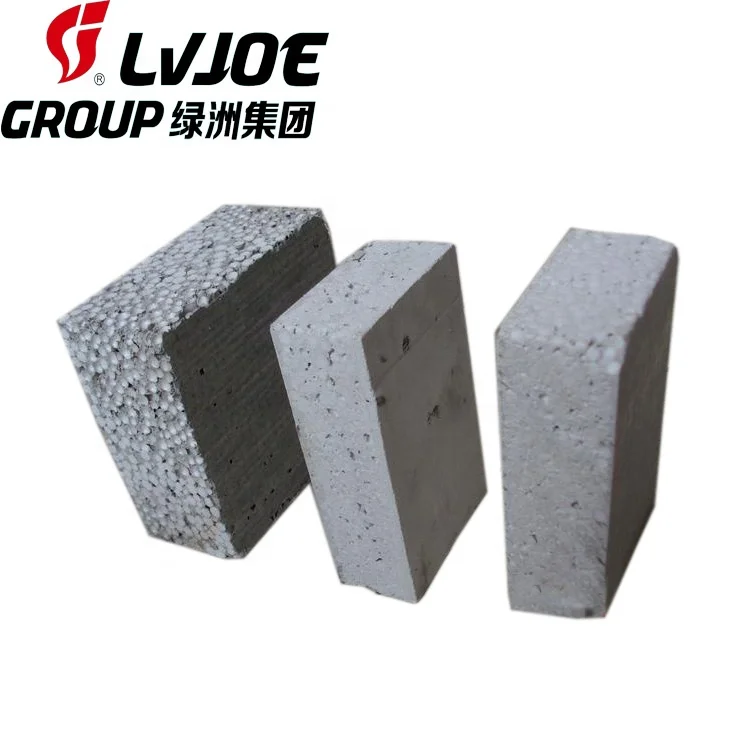

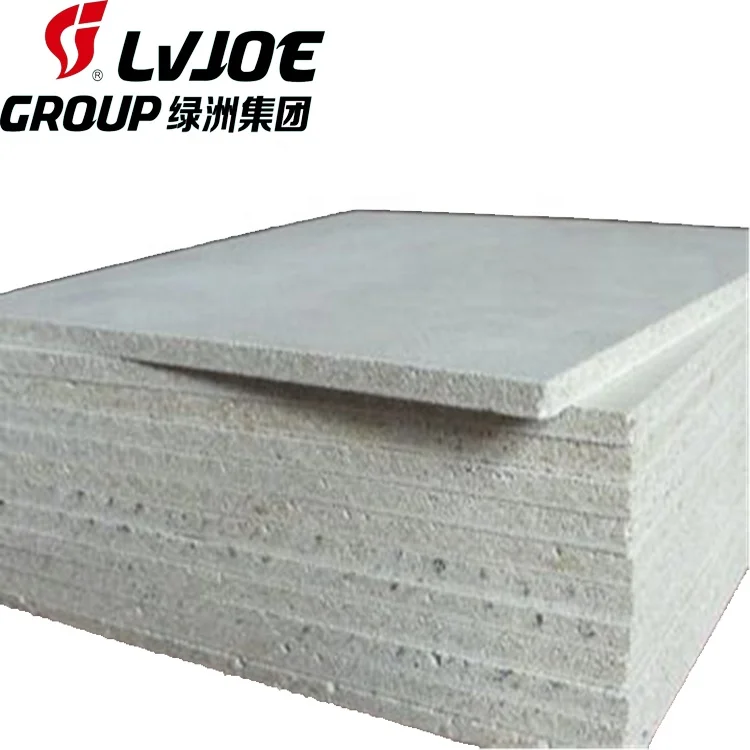

1.The MgO board is environmental friendly, high fireproof and waterproof, can be painted, laminated. nailed and sawn. It is widely used for ceiling, wall panel, decorating of indoor wall and lining board for furniture.

MgO board can replace three-ply board, five-ply board, flakeboard, MDF (Medium Density Fiberboard ) and Gypsum Board.

2.MgO Board performance:

A. Oxygenic index%: >90

B. Level combustion: SO

C. Vertical combustion: SO

D. Water content rate: 10.9%

E. Capacity: 1.15g/cm3

F. Static bending intensity: 169.46Mpa

G. Density: T/ m3 1.13

H. Water resistance: Without chalking for 24 hours and there is no change on surface

I. No “Three-wastes” (waste water, waste gas and waste residue), no pollution and environmental protection

3.Mgo board specifications:

| thickness | 3-20mm |

length*width | 2440*1220mm 2400*900mm 3000*1200mm 2750*1200mm |

1.Batching system

The agitator mixes liquid and solid raw material. It feeds mixed slurry into forming system, providing slurry for forming system.

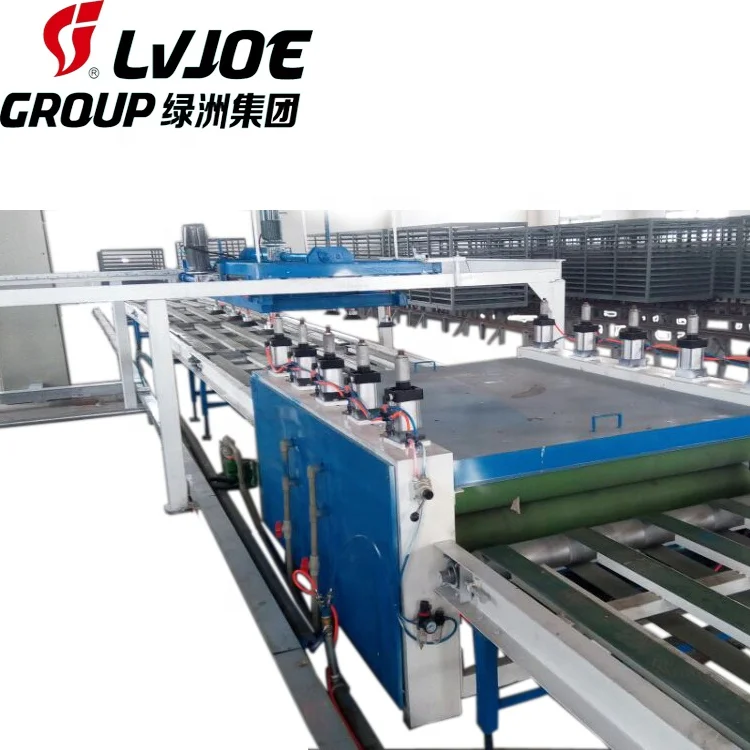

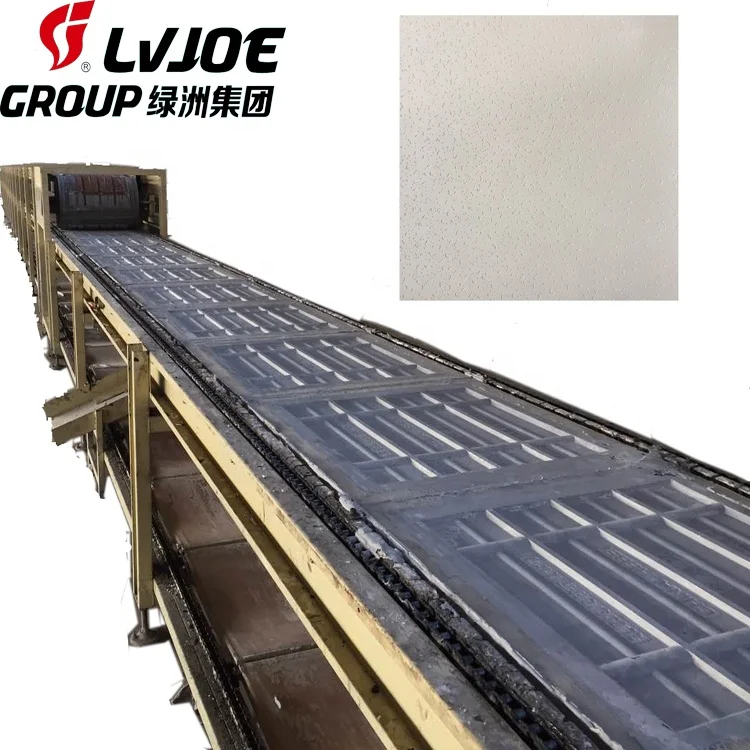

2.Forming line and batching platform

The forming line is the mainframe for the whole line. Mixed wet slurry is fed onto moulding board moving with constant speed, via a storage tank and feeder.

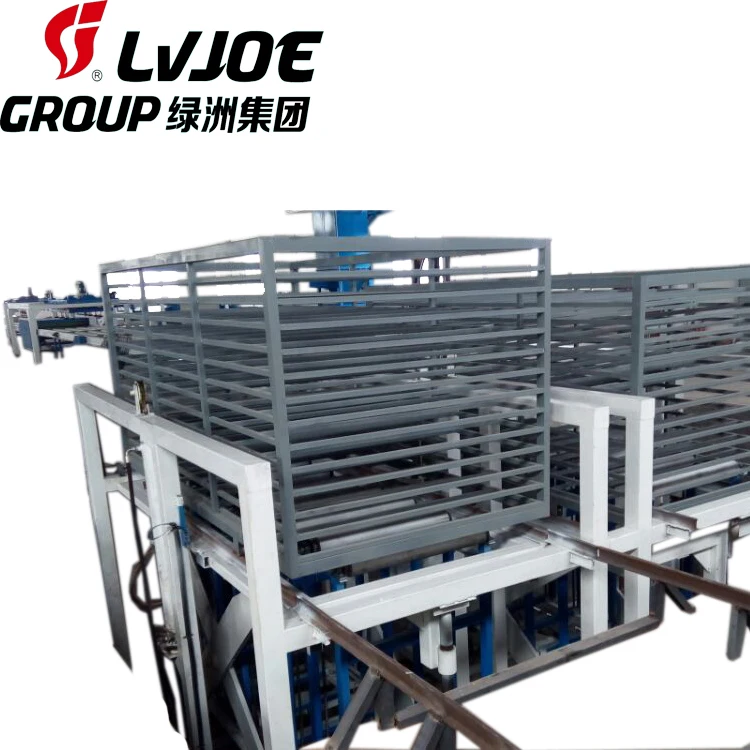

3. Automatic board receiving system:

The wet board will enter the automatic receiving system after has been cut with presetting length.This system adopted microcomputer and double elevators.The wet board with moldboard will enter the curing transporter layer by layer following the order of the microcomputer twenty boards with one curing transporter, and the double elevator achieve process production and volume-produce through alternate use.

4. Solidifying rom with trackway style:

This set of production line is equipped with four trackway,each way can be placed multiple curing transporters and processed solidifying here. The multiple trackway system can meet the purpose of volume-produce.

5.Demoulding machine

This demoulding machine separately absorbs MgO boards and mould board with a vacuum device. It puts MgO board and mould into respective stacking machine separately.

Finished Board

MGO Board Application

1. Best Price; we have our own factory, who has been specialized in full automatic pvc laminated gypsum ceiling tiles machine for more than 15 years, and you are welcome to our factory any time.

2. Superior Quality; quality is the life of all our business.

3. Best Service; we are the special International Trading Company of our factory, and especially focus on exporting business.

4. Best after-sale service; our engineers will design scale of whole production line and help you with installation and commissioning, and train your workers or employees until they know how to operate all equipment.

![IT%_22BZ%5)89DH]KS{XJY7.jpg](http://sc02.alicdn.com/kf/HTB1skIXaI_vK1Rjy0Foq6xIxVXa9/221608432/HTB1skIXaI_vK1Rjy0Foq6xIxVXa9.jpg)

Best regards

James Yang

ADD: 17th, NanYan Road Economical and Technological

Development Zone,Shijiazhuang City,Hebei,China

Mobile Phone:+8615832254694

WeChat:15832254694

E-mail:lvjoe3ATgreensontech.com