Высококачественное компактное покрытие для распыления магнетрона постоянного тока с золотой мишенью благородного металлического

- Категория: Metal Coating Machinery >>>

- Поставщик: Xiamen,Tmax,Battery,Equipments,Limited

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.61 $* | 0.13 $* |

| Aug-20-2025 | 0.49 $* | 0.63 $* |

| Jul-20-2025 | 0.65 $* | 0.32 $* |

| Jun-20-2025 | 0.14 $* | 0.60 $* |

| May-20-2025 | 0.92 $* | 0.12 $* |

| Apr-20-2025 | 0.97 $* | 0.47 $* |

| Mar-20-2025 | 0.41 $* | 0.56 $* |

| Feb-20-2025 | 0.39 $* | 0.61 $* |

| Jan-20-2025 | 0.5 $* | 0.47 $* |

Характеристики

Compact DC Magnetron Sputtering Coater High Quality With Gold Target for Noble Metal Coating

Features

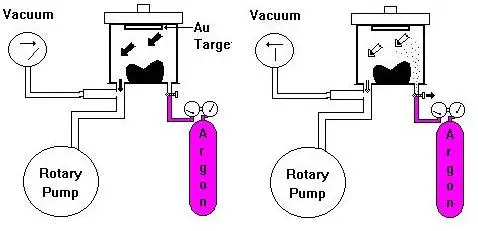

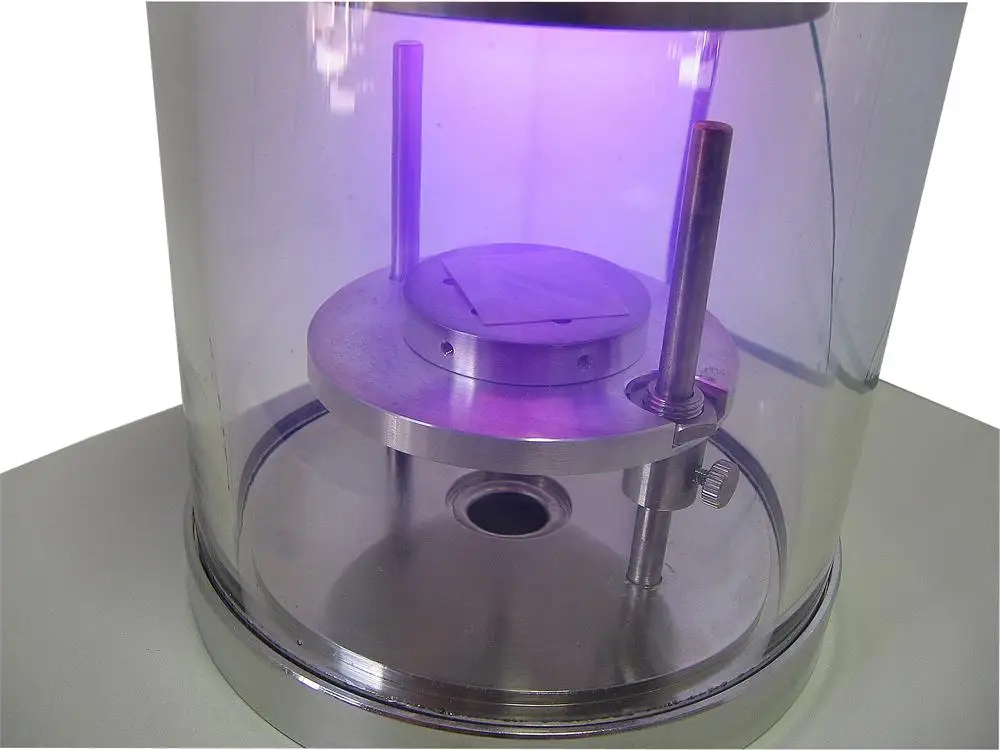

VTC-16-D is a Desktop Magnetron Plasma Sputtering Coater with a 2" target head, height adjustable sample holder. Especially suit for coating conductive gold film for SEM sample. It is a compact plasma sputtering coater designed for metallic coatings, such as gold, platinum, and silver. One 2" gold (4N) target is included.

Specifications

Product Images

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

1.Which procedure to secure your Quality?

1.Order processing?

2. Shipping methods?

1 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

2 Responsible for the damage during the shipping process, will change the damage part for you for free.

3.Order tracking?

Online order can be tracked by login to your account. Please allow 24 hours after order is shipped to see logging details.

If you need a tracking number for your order, please send an email to us with your order/invoice number.

4. Import/export tax, duty, GSM, Customs Clearance, and etc?

All import/export related expenses are sole responsibility of the buyer; charges will vary from country to country. Please consult with your local import experts or transportation carrier for more details.

5.Lost or Stolen packages?

Please report all lost or stolen packages to us at the earliest possible time. An investigation will be open soon after reporting the incident to us, and a final ruling will be issued by the carrier for the claim after 10-15 business days. A replacement package will be sent as soon as the claim is accepted by the responsible carrier.