Линия по производству косметики на 300 литров гидравлический подъемный вакуумный эмульгирующий миксер мазь Миксер для

- Категория: Смесительное оборудование >>>

- Поставщик: Guangzhou,Jutao,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 336106.22 $* | 352911.40 $* |

| Aug-16-2025 | 333282.58 $* | 349946.49 $* |

| Jul-16-2025 | 279618.10 $* | 293599.72 $* |

| Jun-16-2025 | 327633.51 $* | 344015.40 $* |

| May-16-2025 | 285266.64 $* | 299529.1 $* |

| Apr-16-2025 | 321984.91 $* | 338083.68 $* |

| Mar-16-2025 | 319159.47 $* | 335117.40 $* |

| Feb-16-2025 | 316335.22 $* | 332152.42 $* |

| Jan-16-2025 | 313511.97 $* | 329187.58 $* |

Характеристики

300 liters cosmetic production line hydraulic lifting vacuum emulsifying mixer cream ointment mixer

Brief introduction

The machine is mainly composed of water pot, oil pot, emulsifying pot, vacuum system, lifting system (optional), electric control system (PLC is optional),operation platform. Vacuum homogenizing emulsifier means that when the materials are under the vacuum condition,it makes use of the emulsifier to extruding,impacting,breaking and turbulence for over 100 thousand times per minute,after reciprocating circulation at high frequency, the fine finished products of stable and high quality without bubbles will be achieved.

Features

1. Native emulsification device at the bottom, can use the emulsifying head circulate in high and low position to choose to use emulsion or the outer loop emulsification. Using to use emulsion or the outer loop emulsification. Using high-speed emulsification equipment collocation slowly scraping edge effect, raw materials can form powerful circulationg water flow, no dead Angle, the product can fully be blended, emulsification, dispersion and homogeneous, forming good uniform molecular structure.This type of emulsion system than traditional emulsification effect is better.

2.This device is composition by Oil tank,Water tank, Vacuum homogenizing emulsifying tank, Water cycle vacuum pump, Heating system, Lifting system, Operation Cabinet, Control system etc. It is the most applicable cream equipment for produce high grade skin care products .

3.Continuous working processing quantity is big and it can produce material circularly and homogenized and also can put positive pressure to produce material on main boiler which is convenient and fast.

4. The homogenizing structure made through German technology adopts the imported double-end mechanical seal effect.The maximum emulsifying rotation speed can reach 3000rpm and the highest shearing fineness can reach 0.2-5 μm.

5. The emulsifying pot lid can adopt hydraulic lifting system, easy to clean and the cleaning effect is more obvious, the emulsifying pot can adopt tilt discharge.

Technical parameter

| Model | Capacity(L) | mixing power(kw) | Mixing Speed(r/min) | Homogenizing power(kw) | Homogenizing speed(r/min) | Heating method |

| JT-E-20 | 20 | 0.37 | 0-40 | 0.75 | 0-3000 | Steam Heating or Electric Heating (optional) |

| JT-E-50 | 50 | 0.37 | 0-40 | 2.2 | 0-3000 | |

| JT-E-100 | 100 | 1.5 | 0-40 | 3 | 0-3000 | |

| JT-E-150 | 150 | 1.5 | 0-40 | 3 | 0-3000 | |

| JT-E-200 | 200 | 1.5 | 0-40 | 4 | 0-3000 | |

| JT-E-350 | 350 | 2.2 | 0-40 | 4 | 0-3000 | |

| JT-E-500 | 500 | 2.2 | 0-40 | 5.5 | 0-3000 | |

Note: In case of inconformity of the data in the table due to technical improvement or customization, the real object shall prevail. |

||||||

Product pictures

Water pot and oil pot: made of high quality stainless steel, there are three layers, inner is SUS316L, middle and outer are SUS304. Also with heating and mixing functions.

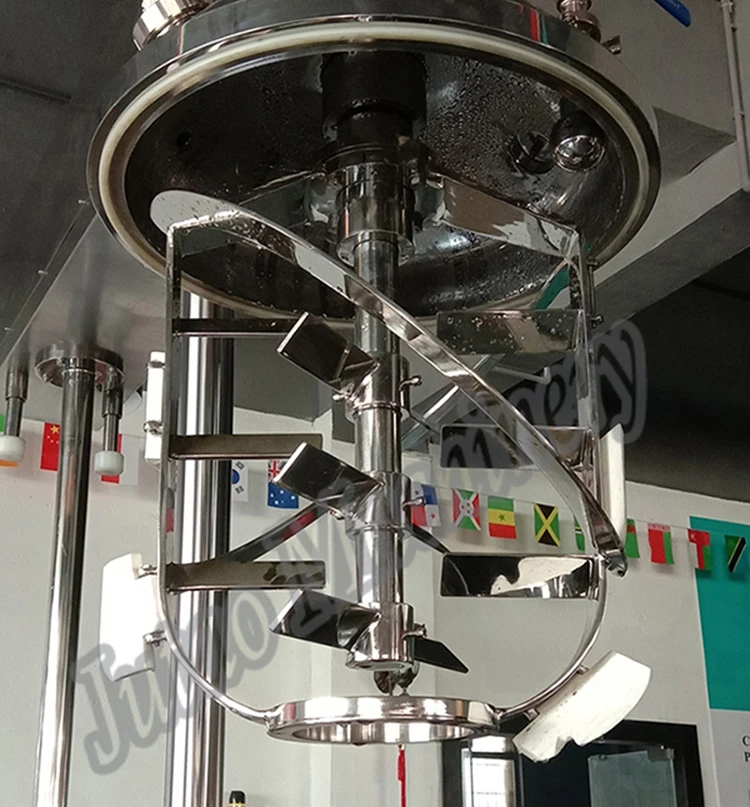

Mixing paddle made of SUS316L stainless steel. the mixing can be single way mixing or double way mixing.

Emulsifying pot lid, there is view window, spice inlet, material inlet, air filter, sight glass light.

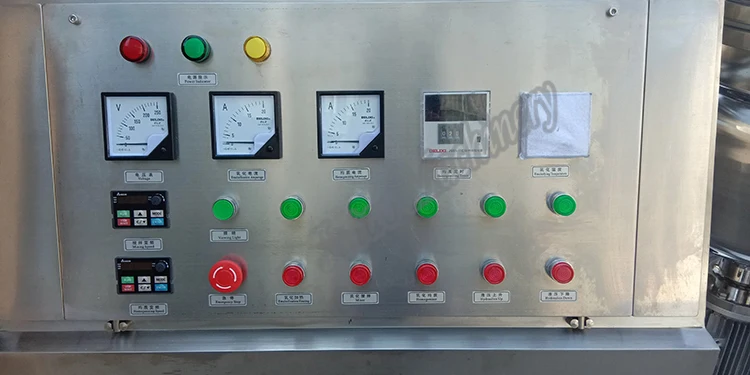

Button control panel, push the button, easy to operate and learn.

High speed homogenizer, made of SUS316L, the rotation speed is 0-3000 round per minute.

Application

Recommend products

Liquid washing homogenizing mixer

Automatic filling and capping machine

Automatic labeling machine

Company Profile

Jutao Machinery is a professional manufacturer of chemical machinery and equipment, accumulating more than ten years of manufacturing experience since its establishment in 1997. Our wide range of products can meet diversified demands of customers. The products include vacuum homogenizing and emulsifying pot series, liquid mixer series, reverse osmosis treatment series, various types of ointment filling machines, liquid filling machines, powder filling machines, labeling machines and other color cosmetic equipment and perfume manufacturing equipment. Our company adheres to the quality concept of "advanced technology and quality foremost", and implements scientific management and continuous improvement. We have won trust from customers with advanced performance, excellent quality, reasonable price and considerate service.

Our factory

Exhibition Center

Certifications

Project Case

We have exported our machine to lots of countries and have world-wide customers over 45 countries. We supply the whole production line, such as cream, ointment, liquid soap, shampoo, hand wash, lotion, detergent etc. And if you only need the single machine, we can also accept.

Our Visitor

We have exported our machine to lots of countries and have world-wide customers over 45 countries, such as United States, Mexico, Thailand, Korea, Malaysia, Vietnam, Spain, Germany, Canada, United Arab Emirates, France, India etc.

Product Packaging

We use the wooden case to pack the machine. It looks beautiful and safe. It is good way to transport the machine to further place. The wooden case can protect the machine during the shippment. And it is suitable for long distance ocean transportation.

FAQ

Our factory is located in Jiangsu province and the showroom is in Guangzhou, China. We have over 10 years experience on cosmetic machinery making.

2.What do we do if we encounter problem about the machine ?

Show us the picture or video of the problem. If the problem can be solved by your workers, we will send you solution by video or pictures. If the problem is out of your control, our engineer will be sent to your factory (customer will pay for the fee during the trip).

3.What about after sale service?

We provide one year warranty period for all equipment, such as vacuum emulsifying mixer machine, liquid washing mixer machine, automatic filling machine, semi auto filling machine, etc. During the warranty time, if you have some questions about the machine, you can contact us and we will try our best to help you.

4. How to finish installing?

Our engineer can be sent to your country. but customer should pay the air tickets. besides, customer should arrange the accommodation for them during the trip.

5. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise that our wooden packaging is strong enough and safety for long delivery.

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com