Прямая продажа с фабрики рекламная оптовая машина для нанесения покрытия на таблетки и

- Категория: Coating Machines >>>

- Поставщик: Changsha,Samy,Instrument,&,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 1499.79 $* | 1574.91 $* |

| Aug-15-2025 | 1487.86 $* | 1561.14 $* |

| Jul-15-2025 | 1247.79 $* | 1309.72 $* |

| Jun-15-2025 | 1462.98 $* | 1535.64 $* |

| May-15-2025 | 1273.85 $* | 1337.99 $* |

| Apr-15-2025 | 1436.95 $* | 1508.93 $* |

| Mar-15-2025 | 1424.77 $* | 1495.23 $* |

| Feb-15-2025 | 1411.66 $* | 1482.9 $* |

| Jan-15-2025 | 1399.93 $* | 1469.24 $* |

Характеристики

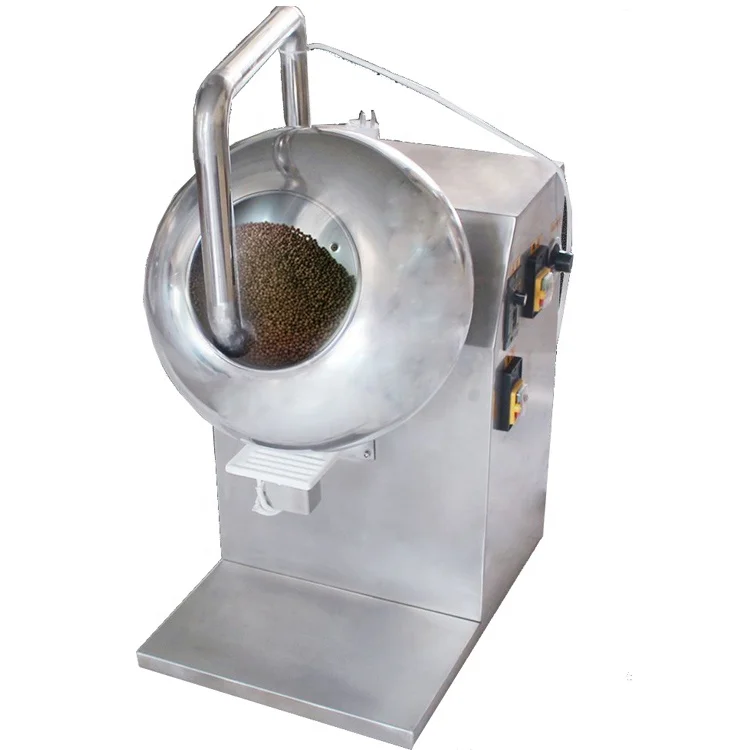

Factory direct promotional wholesale BY-600 Pill Polishing Machine for pills and tablets

The candy coating machine is used in the pharmaceutical industry to make molded chip be coated uniformly and polished, also can be used in food industry for candy pills or coating.

The coated tablet after polishing has the bright color surface, and the complete fixed structure covering, which produced from crystal sugar of the surface, can prevent the tablet chip from oxidation, moisture or volatile, also can cover the uncomfortable taste when take the tablet, it has some effect with easy to identify the tablet and neutralize the solution in the intestines and stomach and other.

The candy coating machine can make all kind of candy and tablet covered different colors as you want.

Control button.

The control button on the machine can adjust the heating fan and cooling fan speed

Ventilation fan.

Safe explosion - proof, adjustable speed, easy to use, low noise features

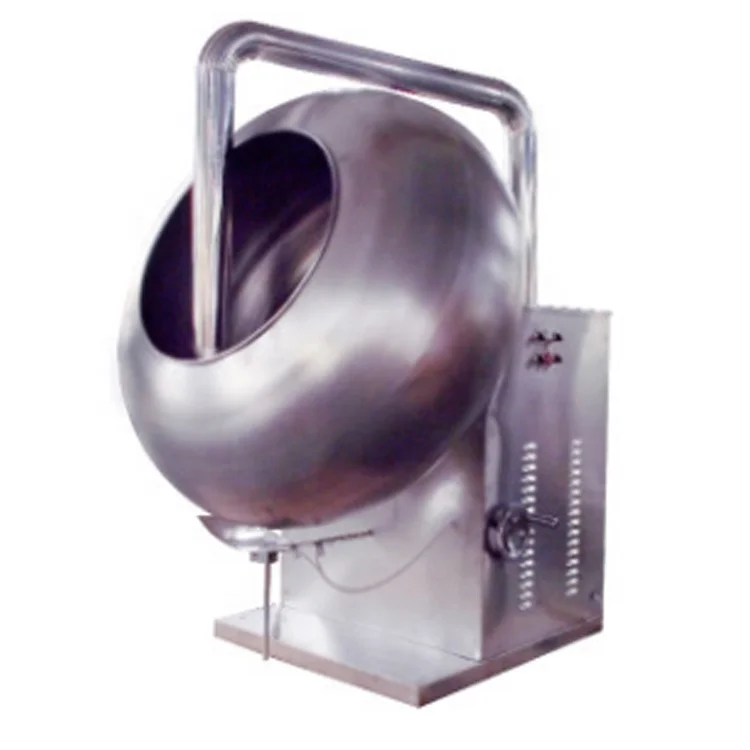

Stainless steel candy drum.

The drum is tilted at an Angle of 30 degrees up horizontally, turning smoothly and exchanging frequently, avoiding debris and collision

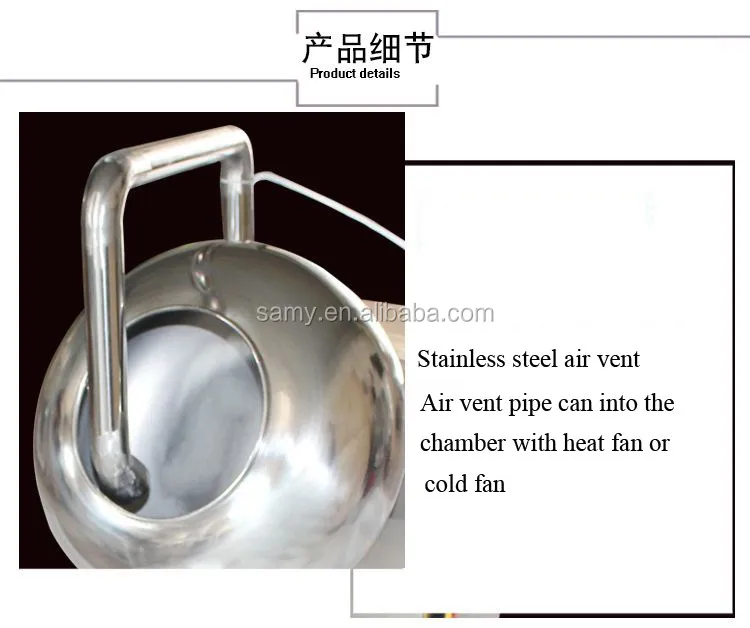

Stainless steel vent pipe.

The air outlet pipe can be extended into the ball for heating or cooling air.

Diameter of sugarcoating diameter | 600 mm | Capacity | 5-15㎏/time |

The power of main motor | 120W | Roataion speed of sugarcoating dish | 8-80r/min |

Air Volume of blowing machine | 1.1m3/min | Fan power | 60W |

Hot-blast outlet temperature | 30-80m℃ | Footprint area | 680×550x1120㎜ |

Height | 860㎜ | Weight | 100㎏ |

Compressed air pressure | 4-6kg/cm | Electric heating power | 900W |

Working principle.

In order to make the chip evenly coated crystal as soon as possible on the surface, and to achieve the objective of polishing, it must be with a manually operation to spray compound syrup and mixing element to the pot repeatedly recurringly. Sugar coated tablets roll in the pot through the clockwise of pot, the tablets are uniformly distributed in the whole chip, and then make the hot air to the pot to remove surface moisture of the tablet, get a qualified sugar coated chip finally.

The machine can provide the best pot for the coating process, it can It is in a stable line speed to ensure the best logistics in the form of tablets curve, to meet process requirements which are the thickness of coating uniformly, bright color, no pitting.

Before order

Professional technical advice

According to customer need to select the appropriate Product Type, OEM\\ODM available

Product testing program proposal

Order confirmation & contract based on customer requirements

During Production

Customer communication, progress reported

Instructions for installation, commissioning, testing, etc.

After Service

Regular on-line advisory

Simple faults online consultation

E-mail consultation feedback within 24hours

Lifetime offer replacement parts but need to be paid

Engineer available to service machinery overseas but need extra cost