Оптовая продажа самая низкая цена машина для сублимационной

- Категория: Передача тепла >>>

- Поставщик: Guangzhou,Xin,Flying,Digital,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 10591.70 $* | 11121.67 $* |

| Aug-18-2025 | 10502.36 $* | 11027.13 $* |

| Jul-18-2025 | 8811.68 $* | 9252.81 $* |

| Jun-18-2025 | 10324.11 $* | 10840.13 $* |

| May-18-2025 | 8989.41 $* | 9438.88 $* |

| Apr-18-2025 | 10146.52 $* | 10653.72 $* |

| Mar-18-2025 | 10057.61 $* | 10560.41 $* |

| Feb-18-2025 | 9968.13 $* | 10466.49 $* |

| Jan-18-2025 | 9879.36 $* | 10373.75 $* |

Характеристики

Parameter:

Product model | InkFa 4217 | InkFa 6017 |

Specification | 420*1700mm | 600*1700mm |

Roller diameter | 420mm | 600mm |

Transfer width | 1600mm | |

Voltage | 3 phase 220V/380V | |

Operation power | 28kw | 34kw |

Transfer speed | 100-200m/h | 150-280m/h |

Heating type | Oil heating | |

Working table | 3m | |

Heating type | Oil heating | |

Temperature range | 0-399°C | |

Operate method | Three putting,two receiving | |

Transfer model | Both roll and sheet fabric | |

Pressure | With pressure strengthen system | |

Packing size | 1150*1280*2880mm | 1300*1530*2880mm |

Weight | 1400kg | 1800kg |

Features:

1.High-end composite steel roller with Teflon surface coated,Uniform drum temperature and lower energy consumption;

2.Equipped with adjustable pneumatic pressure system, adjust the pressure according to different

transfer materials, the transfer speed is faster, the color is more gorgeous;

3.Self-developed equipment control system, using high-end electrical components, high-precision parts, equipment transfer more stable;

4.The blanket is separated automatically and the high-precision silicone pressure balance bar is

used to adjust the pressure between the blanket and the roller to effectively reduce the tension of the blanket and extend the service life of the blanket;

5.Adopt scientific design, three putting and two rewinding(three putting: putting fabric,transfer paper,

and protection paper; two rewinding; rewinding fabric and protection paper) ,equipment operation is more convenient,labor saving;

Double layer oil drum,100% full heating oil,the surface temperature is ±1-2ºC;

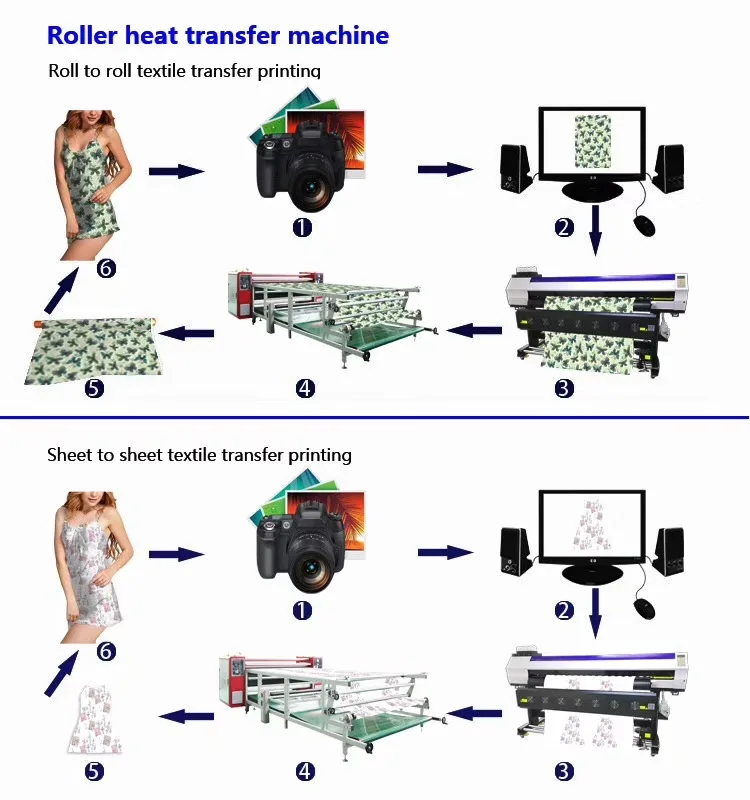

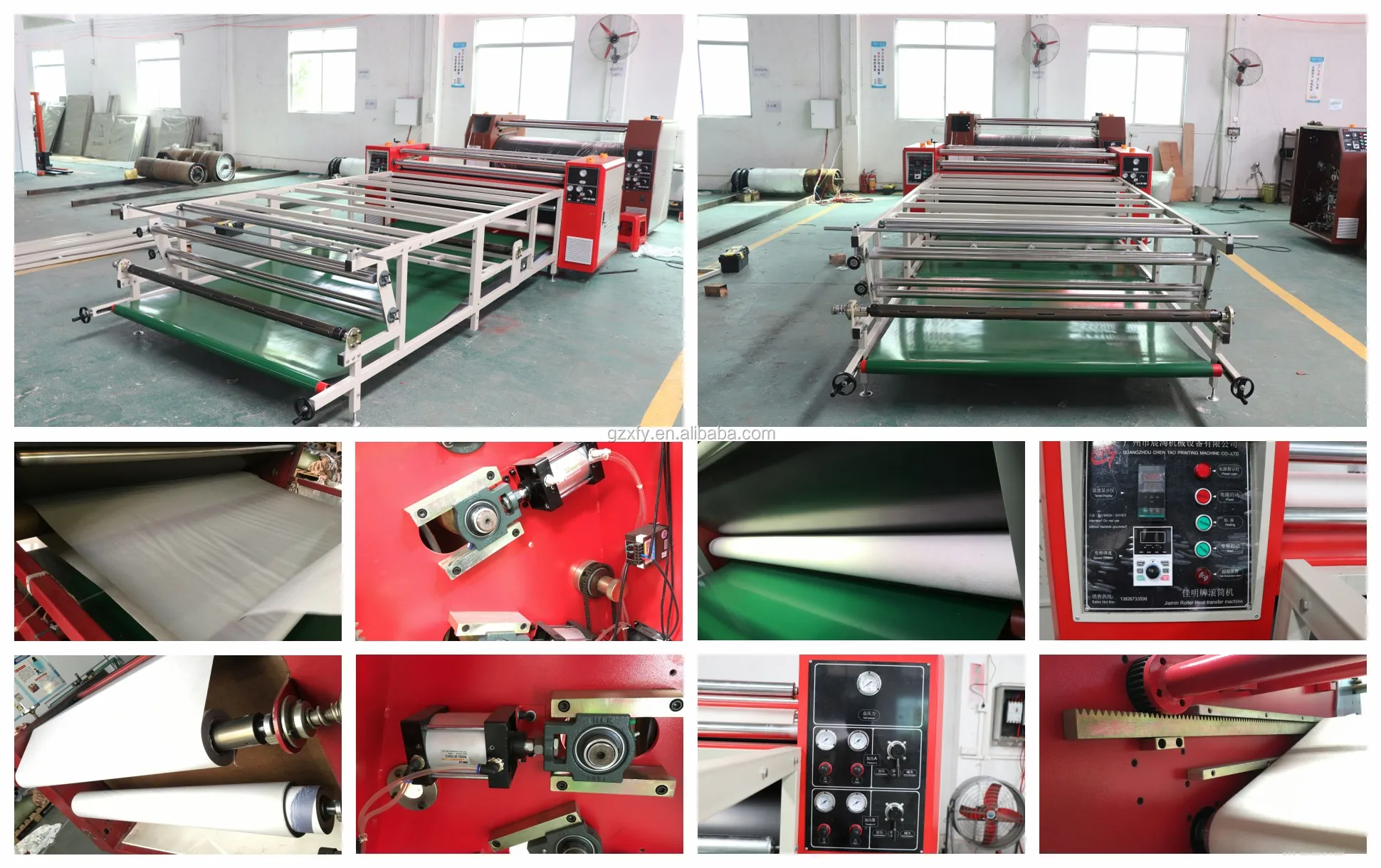

Roller heat transfer machine details

1. Protect paper controller which is adjsuting collecting speed.

2. External pressure system independent switch, pressure control button, easy to operate

3. Emergency stop device. If there is an emergency, press the emergency stop device, the machine will stop immediately, safety is higher.

4. The cylinder pressurizing device is that the cloth and the blanket are closely attached to the roller, and the blanket is not easy to be deflected.

5.Carbon brush type collector ring, which can work continuously for 24 hours, stable current transmission and high safety

6.Adopting DuPont full aramid blanket, the blanket is resistant to high temperature, not easy to deform, the surface is smooth, and the fabric transfer has no color difference.

Appliciton:

It is suitable for sublimation transfer large banners , flags,T-shirt,non-woven fabrics, apparel fabrics, towels, blankets,

mouse pads and other products in the piece, especially the continuous transfer of the cloth.Capable of continuous printing speed,

to meet the needs of large volume printing the customer.